High-speed foot cutting die for LED lead frame

A lead frame, high-speed technology, applied in the field of LED lead frame high-speed cutting dies, can solve the problems of unstable stamping production quality, no oil supply, and high quality requirements for LED lead frames.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

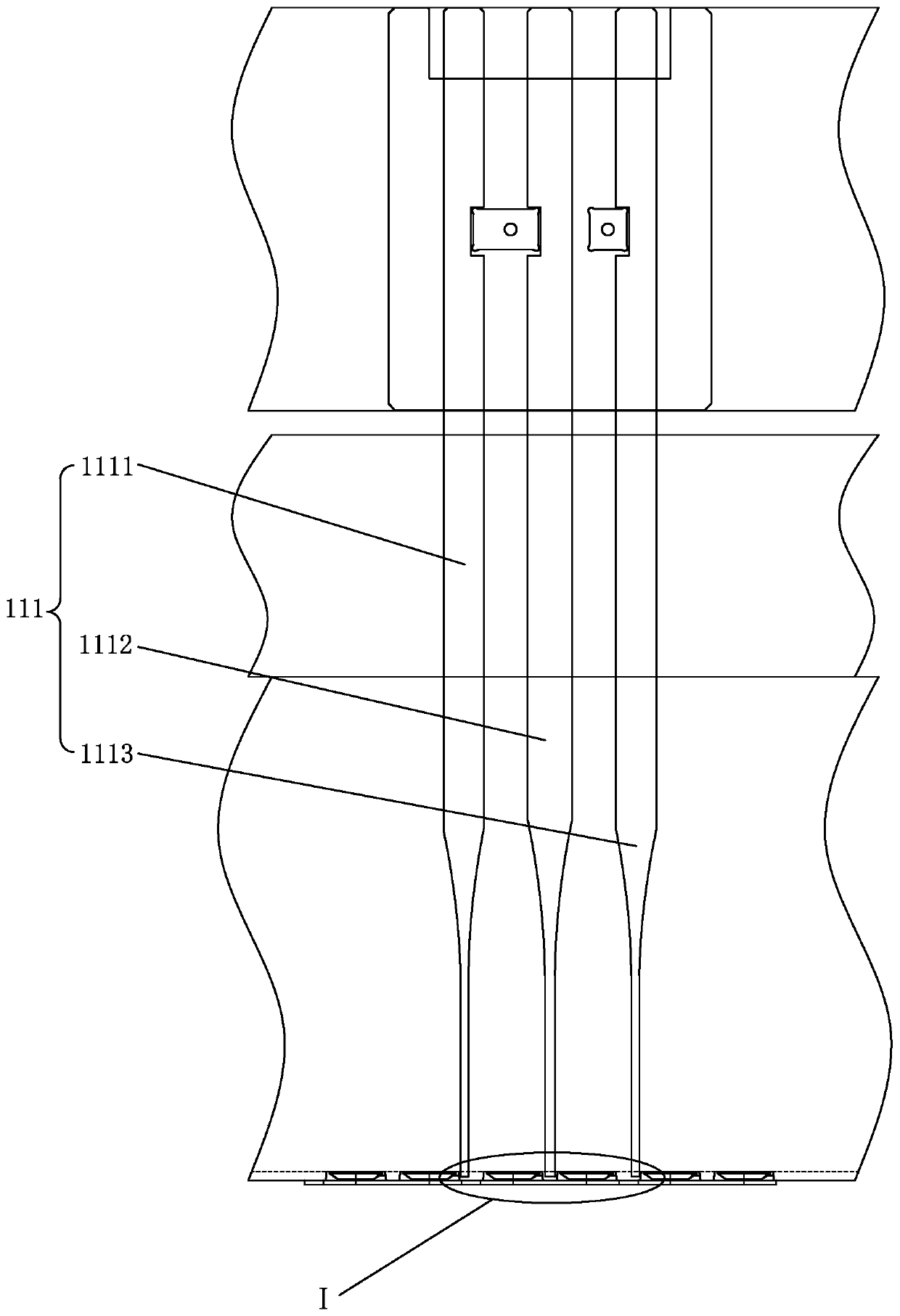

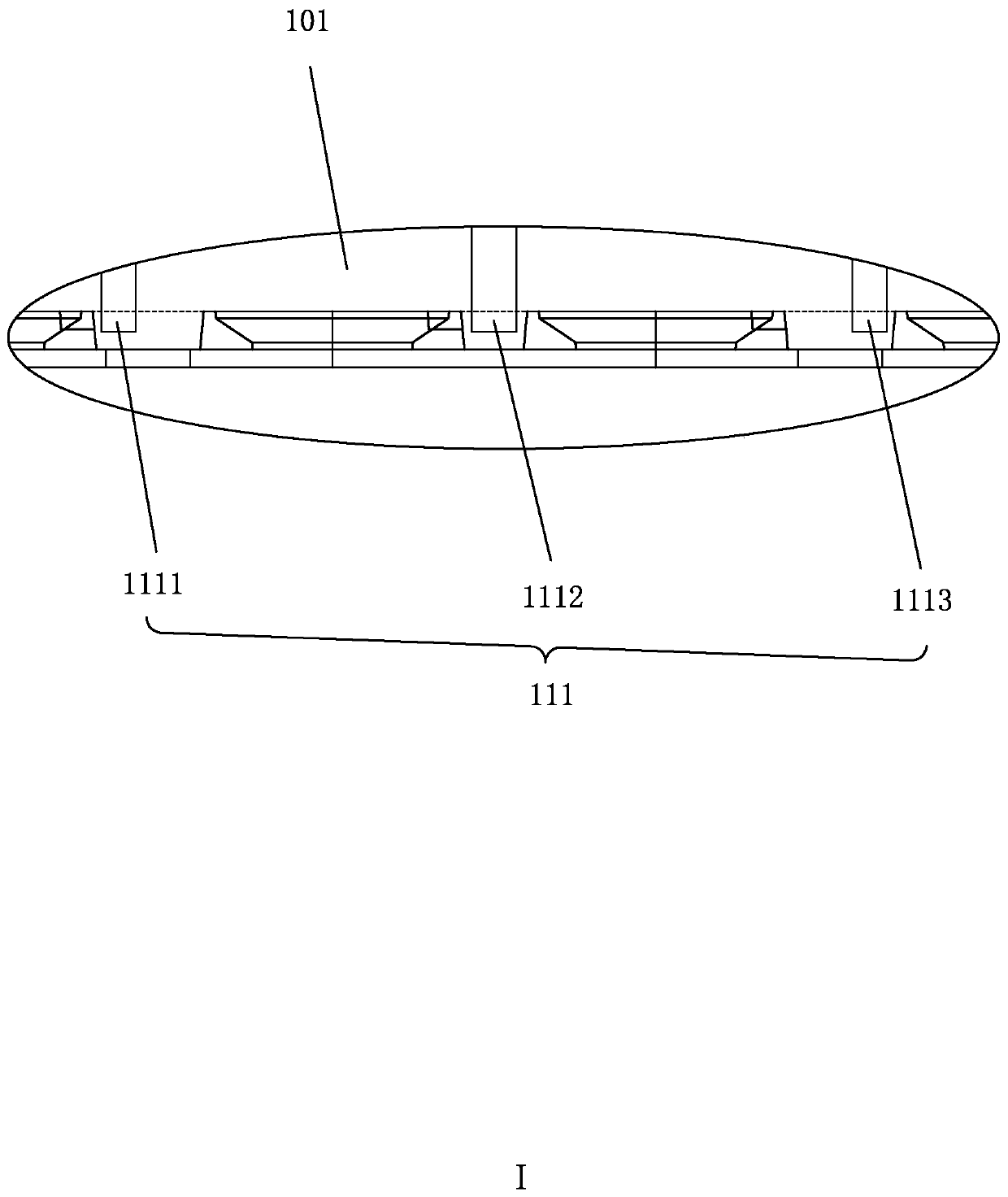

[0038] Such as Figure 1-15 As shown, the LED lead frame high-speed foot cutting die includes an upper die set 1 and a lower die set 2 adapted to the upper die set 1 .

[0039]Specifically, the upper die set 1 is provided with a first punch group 11 and a second punch group 12 located on one side of the first punch group 11, and the first punch group 11 includes at least one set of the first punch group 12. A punch group 111, the second punch group 12 includes at least one set of second punch groups 121, the first punch group 111 and the second punch group 121 are along the longitudinal direction of the upper die group 1 The directions are staggered, and the punching ends of the first punch group 111 and the second punch group 121 protrude from the lower side of the upper die group 1;

[0040] The lower die group 2 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com