A kind of internal combustion engine cylinder body surface treatment process

A technology of internal combustion engine cylinder and treatment process, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of large thermal shock, restricting the comprehensive performance of the generator set, and high working temperature, and achieves enhanced bonding force, safety and convenience. Excellent effect of cost and thermal shock strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

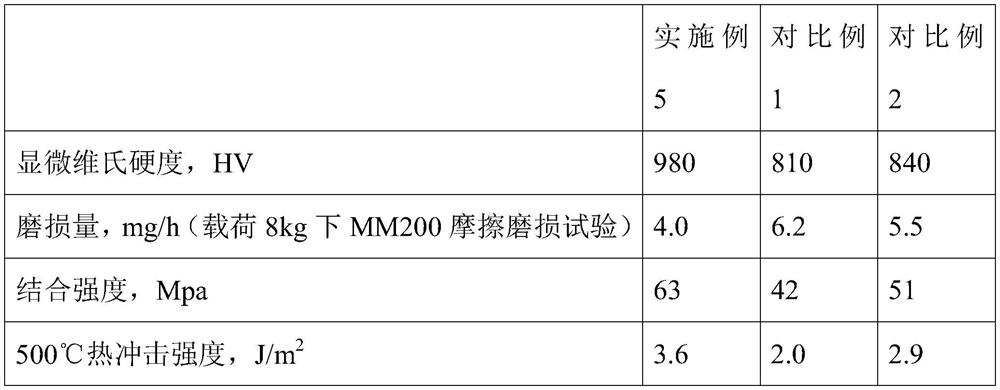

Examples

Embodiment 1

[0024] A surface treatment process for an internal combustion engine cylinder, comprising the steps of:

[0025] S1. Put sodium hexametaphosphate, sodium silicate, sodium carbonate, sodium tungstate, sodium aluminate, and disodium edetate into water and stir evenly to obtain an electrolytic solution with a pH value of 10.1; wherein sodium hexametaphosphate The concentration is 28g / L, the concentration of sodium silicate is 4g / L, the concentration of sodium carbonate is 10g / L, the concentration of sodium tungstate is 1g / L, the concentration of sodium aluminate is 1.8g / L, ethylenediaminetetra The concentration of disodium acetate is 1g / L;

[0026] S2. The aluminum alloy cylinder block of the internal combustion engine to be processed is used as an anode, and a stainless steel tube is placed inside the aluminum alloy cylinder block of the internal combustion engine to be processed as a cathode. First solution guide pipes are respectively provided at both ends of the aluminum allo...

Embodiment 2

[0030] A surface treatment process for an internal combustion engine cylinder, comprising the steps of:

[0031] S1. Put sodium hexametaphosphate, sodium silicate, sodium carbonate, sodium tungstate, sodium aluminate, and disodium edetate into water and stir evenly to obtain an electrolytic solution with a pH value of 13; wherein sodium hexametaphosphate The concentration is 22g / L, the concentration of sodium silicate is 8g / L, the concentration of sodium carbonate is 5g / L, the concentration of sodium tungstate is 4g / L, the concentration of sodium aluminate is 1g / L, ethylenediaminetetraacetic acid The concentration of disodium is 2g / L;

[0032] S2. The aluminum alloy cylinder block of the internal combustion engine to be processed is used as an anode, and a stainless steel tube is placed inside the aluminum alloy cylinder block of the internal combustion engine to be processed as a cathode. First solution guide pipes are respectively provided at both ends of the aluminum alloy ...

Embodiment 3

[0036] A surface treatment process for an internal combustion engine cylinder, comprising the steps of:

[0037] S1. Put sodium hexametaphosphate, sodium silicate, sodium carbonate, sodium tungstate, sodium aluminate, and disodium edetate into water and stir evenly to obtain an electrolytic solution with a pH value of 11; wherein sodium hexametaphosphate The concentration is 26g / L, the concentration of sodium silicate is 5g / L, the concentration of sodium carbonate is 8g / L, the concentration of sodium tungstate is 2g / L, the concentration of sodium aluminate is 1.6g / L, ethylenediaminetetra The concentration of disodium acetate is 1.3g / L;

[0038]S2. The aluminum alloy cylinder block of the internal combustion engine to be processed is used as an anode, and a stainless steel tube is placed inside the aluminum alloy cylinder block of the internal combustion engine to be processed as a cathode. First solution guide pipes are respectively provided at both ends of the aluminum alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com