Chlorine ion curing agent for reinforced concrete and preparation method and applications thereof

A technology of reinforced concrete and curing agent, which is applied in the field of chloride ion curing agent for reinforced concrete and its preparation, can solve the problems of high cost of replacing steel bars, high desorption rate, poor adhesion and toughness, etc. stability, complete crystal structure, and the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

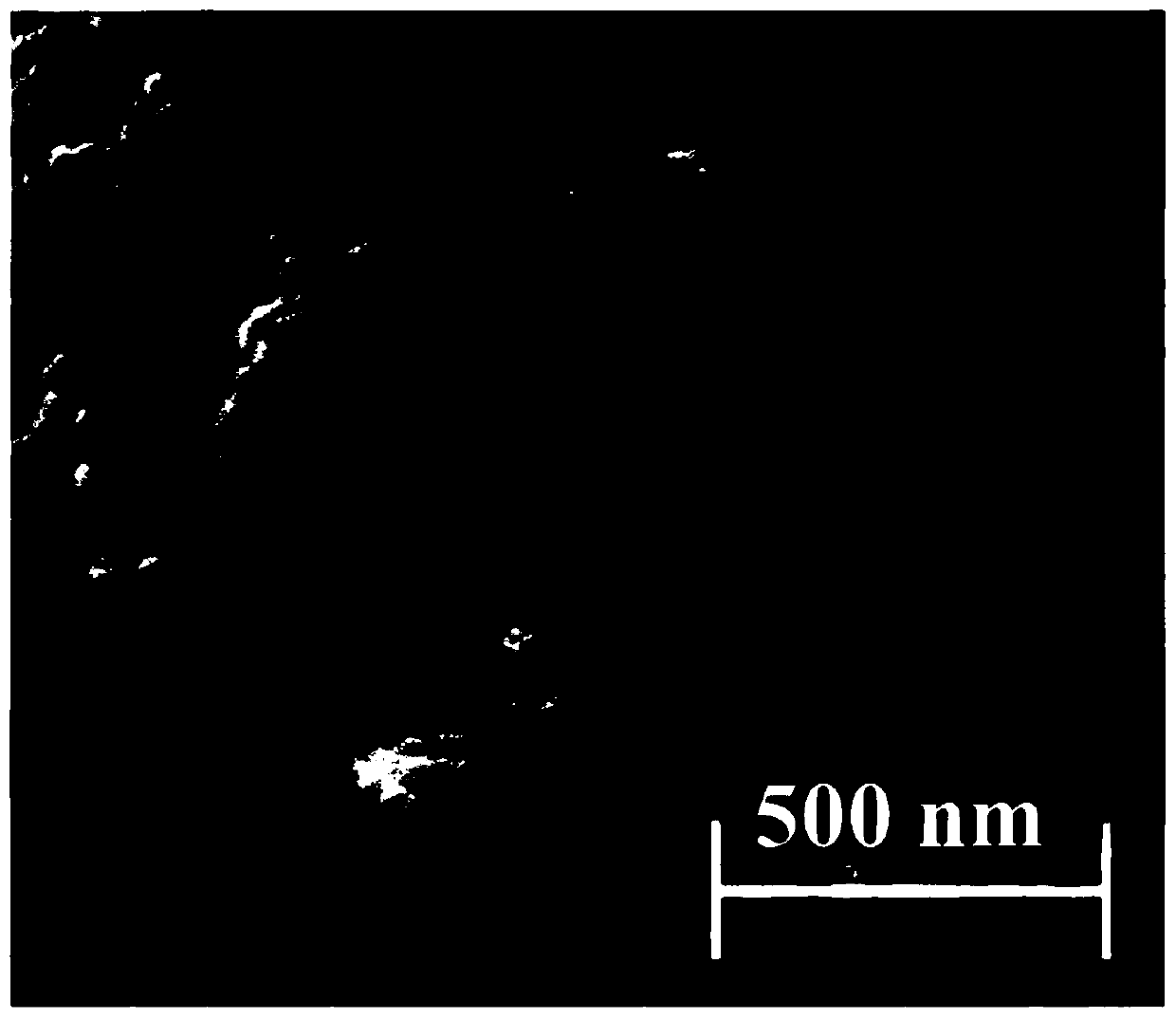

Image

Examples

Embodiment 1

[0041] A preparation method of a chloride ion curing agent for reinforced concrete, comprising the steps of:

[0042] 1. CaFe-NO 3 Synthesis and preparation of LDHs: Dissolve 10mmol of calcium nitrate and 5mmol of ferric nitrate in 100mL of distilled water to make solution A; add solution A dropwise into 30mL of 1mol / L sodium hydroxide solution (air flow rate is 100ml / min Nitrogen protection), magnetic stirring for 36 hours after the titration is completed, then filtered to neutral, dried in a vacuum oven at 80°C for 12 hours, and the obtained product was ground into powder to obtain the final product.

[0043] 2. CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 100mmol of calcium nitrate, 10mmol of iron nitrate, and 40mmol of aluminum nitrate in 100mL of distilled water to prepare solution B; dissolve 240mmol of sodium hydroxide and 120mmol of sodium nitrate in 100mL of distilled water to prepare C solution; add B solution and C solution dropwise into a three-necke...

Embodiment 2

[0045] A preparation method of a chloride ion curing agent for reinforced concrete, comprising the steps of:

[0046] 1. CaFe-NO 3 Synthesis and preparation of LDHs: Dissolve 40mmol of calcium nitrate and 15mmol of ferric nitrate in 100mL of distilled water to make solution A; add solution A dropwise to 100mL of 1mol / L sodium hydroxide solution (air flow rate is 100ml / min Nitrogen protection), magnetic stirring for 12 hours after the titration, then filtering to neutrality, drying in a vacuum oven at 60°C for 24 hours, and grinding the obtained product into powder to obtain the final product.

[0047] 2. CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 30mmol of calcium nitrate, 5mmol of iron nitrate, and 10mmol of aluminum nitrate in 120mL of distilled water to prepare solution B; dissolve 80mmol of sodium hydroxide and 100mmol of sodium nitrate in 120mL of distilled water to prepare C solution; add B solution and C solution dropwise into a three-necked flask at th...

Embodiment 3

[0049] A preparation method of a chloride ion curing agent for reinforced concrete, comprising the steps of:

[0050] 1. CaFeL-NO 3 Synthesis and preparation of DHs: Dissolve 50mmol of calcium nitrate and 25mmol of ferric nitrate in 120mL of distilled water to form solution A; add solution A dropwise into 140mL of 1mol / L sodium hydroxide solution (air flow rate is 100ml / min Nitrogen protection), magnetically stirred for 48 hours after the titration, filtered until neutral, dried in a vacuum oven at 120°C for 6 hours, and ground the obtained product into powder.

[0051] 2. CaFeAl-NO 3 Synthesis and preparation of LDHs: Dissolve 150mmol of calcium nitrate, 20mmol of iron nitrate, and 50mmol of aluminum nitrate in 150mL of distilled water to prepare solution B; dissolve 300mmol of sodium hydroxide and 200mmol of sodium nitrate in 150mL of distilled water to prepare C solution; add B solution and C solution dropwise into a three-necked flask at the same time, stir for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com