Method for modifying water-based lubricating fluid with wood flour-soybean lecithin

A technology of soybean lecithin and water-based lubricating fluid, applied in the field of lubricating fluid, can solve problems such as insufficient lubrication performance and poor wear resistance, and achieve the effect of improving compatibility and antirust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

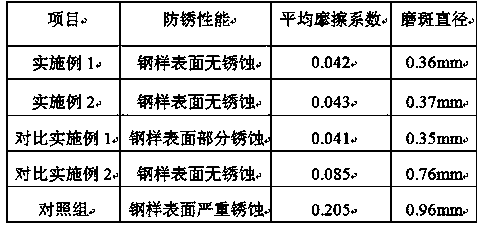

Examples

Embodiment 1

[0030] A method for modifying water-based lubricating liquid with wood flour-soybean lecithin is characterized in that it comprises the following steps, and the following raw materials are by weight:

[0031] (1) Compound modification of wood flour:

[0032] Put 4 parts of wood flour into a high-speed mixer, add 0.1 part of KH550, treat at 105°C for 10 minutes, then add potassium hydroxide solution at 1:5, stir for 1 hour, let stand, wash with water until neutral, dry and pulverize, Obtain composite modified wood flour;

[0033] Wherein, the potassium hydroxide solution mass concentration is 5%;

[0034] (2) Modification of soybean lecithin:

[0035] Heat 6 parts of soybean lecithin to 70°C, stir with nitrogen gas for 10 minutes, add 1 part of lactic acid and 1 part of hydrogen peroxide, and react at constant temperature for 2 hours to obtain hydroxylated modified soybean lecithin;

[0036] Wherein, the hydrogen peroxide concentration is 25%;

[0037] (3) Modification of w...

Embodiment 2

[0042] A method for modifying water-based lubricating liquid with wood flour-soybean lecithin is characterized in that it comprises the following steps, and the following raw materials are by weight:

[0043] (1) Compound modification of wood flour:

[0044] Put 7 parts of wood flour into a high-speed mixer, add 0.2 parts of KH550, treat at 110°C for 5 minutes, add 1:5 into potassium hydroxide solution, stir for 2 hours, let stand, wash with water until neutral, dry and pulverize, Obtain composite modified wood flour;

[0045] Wherein, potassium hydroxide solution mass concentration is 10%;

[0046] (2) Modification of soybean lecithin:

[0047] Heat 9 parts of soybean lecithin to 75°C, stir for 10 minutes with nitrogen gas, add 2 parts of lactic acid and 2 parts of hydrogen peroxide, and react at constant temperature for 1 hour to obtain hydroxylated modified soybean lecithin;

[0048] Among them, the concentration of hydrogen peroxide is 35%;

[0049] (3) Modification of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com