Yoghourt with sleeping effect and making method of yoghourt

A yogurt and action technology, applied in milk preparations, other dairy products, applications, etc., can solve the problem of preparing yogurt without peanut vines, and achieve the effects of reducing the increase in acidity, uniform organization, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

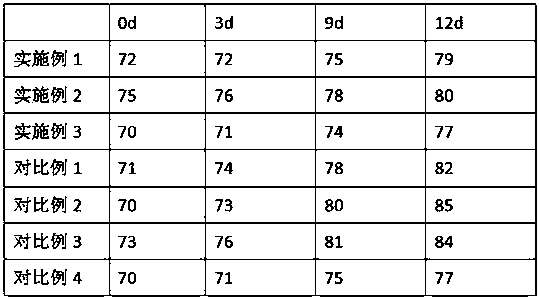

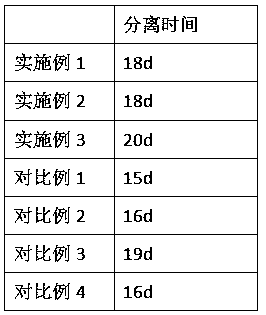

Examples

Embodiment 1

[0022] (1) Select 11 parts of fresh peanut vines free from diseases and pests, blanching at 70-80°C for 3 minutes, cut the blanched peanut vines into sections, add 5 times the volume of ice water, 3 parts of seafood mushroom superfine powder, and homogenate 10min, the homogenate was firstly hydrolyzed by 1% of its mass with neutral protease for 30min; then added with 0.2% of its mass by cellulase for 30min; finally added with 0.2% of its mass by pectinase for 30min

[0023] , then utilize non-woven fabric to filter and remove slag, add 0.01 part of flavoring agent, 0.015 part of glycyrrhizic acid and 0.01 part of cysteine to the filtrate, mix evenly to obtain peanut vine juice;

[0024] The flavoring agent is composed of citric acid, sodium pyrophosphate and calcium citrate in a mass ratio of 2:0.1:1;

[0025] (2) Mix peanut vine juice with 80 parts of milk and 12 parts of white sugar, and sterilize and cool the mixture;

[0026] (3) After cooling, inoculate the mixed solut...

Embodiment 2

[0028] (1) Select 10 parts of fresh peanut vines free from diseases and pests, blanching at 70-80°C for 3 minutes, cut the blanched peanut vines into sections, add 5 times the volume of ice water, 4 parts of seafood mushroom superfine powder, and homogenate 10min, the homogenate was firstly hydrolyzed by 2% of its mass with neutral protease for 20min; then added with 0.2% of its mass by cellulase for 20min; finally added with 0.2% of its mass by pectinase for 30min

[0029] , then utilize non-woven fabric to filter and remove slag, add 0.02 part of flavoring agent (same as Example 1), 0.02 part of glycyrrhizic acid and 0.01 part of cysteine to the filtrate, mix evenly to obtain peanut vine juice;

[0030] (2) Mix peanut vine juice with 90 parts of milk and 15 parts of white sugar, and sterilize and cool the mixture;

[0031] (3) After cooling, inoculate the mixed solution with lactic acid bacteria, then cultivate and check the acidity of the product at 42±2°C until the acidi...

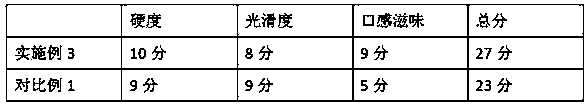

Embodiment 3

[0033] (1) Select 12 parts of fresh peanut vines free from diseases and pests, blanching at 70-80°C for 3 minutes, cut the blanched peanut vines into sections, add 5 times the volume of ice water, 5 parts of seafood mushroom superfine powder, and homogenate 10min, the homogenate was first added with 2% of its mass by neutral protease for 20min; then added with 0.2% of its mass by cellulase for 20min; finally added with 0.2% of its mass by pectinase for 30min, Then use non-woven fabric to filter and remove slag, add 0.03 part of flavoring agent (same as Example 1), 0.02 part of glycyrrhizic acid and 0.012 part of cysteine to the filtrate, mix evenly to obtain peanut vine juice;

[0034] (2) Mix peanut vine juice with 100 parts of milk and 10 parts of white sugar, and sterilize and cool the mixture;

[0035] (3) After cooling, inoculate the mixed liquid with lactic acid bacteria, then cultivate and check the acidity of the product at 42±2°C until the acidity is 70°T, then take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com