Method for controlling post-acid of yoghurt

A technology of yogurt and acidity, applied in the direction of milk preservation, bacteria used in food preparation, dairy products, etc., can solve the problems of product flavor texture influence, high adjustment dependence, and post-acidity, so as to avoid product state Not good, long shelf life, extended shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

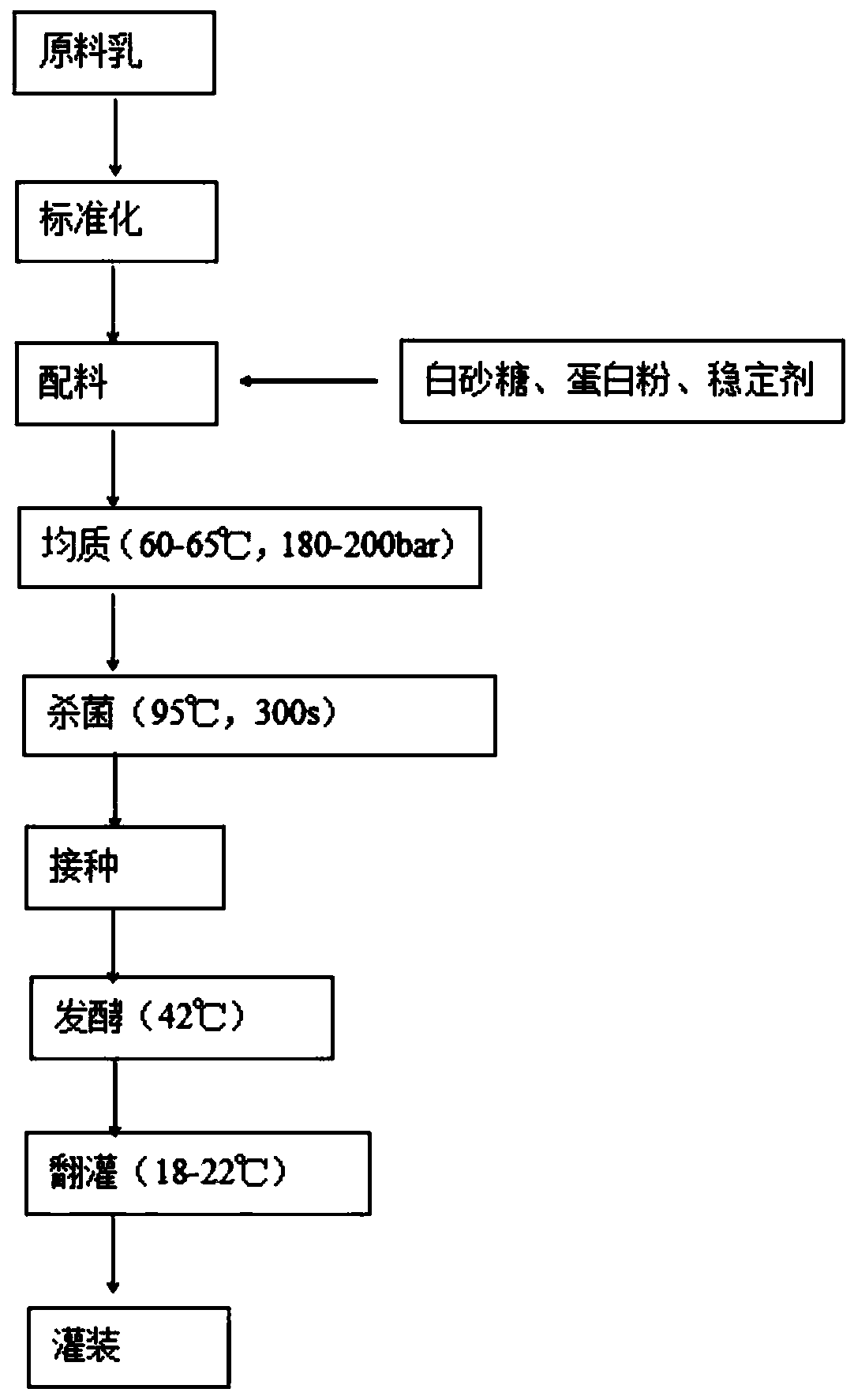

Method used

Image

Examples

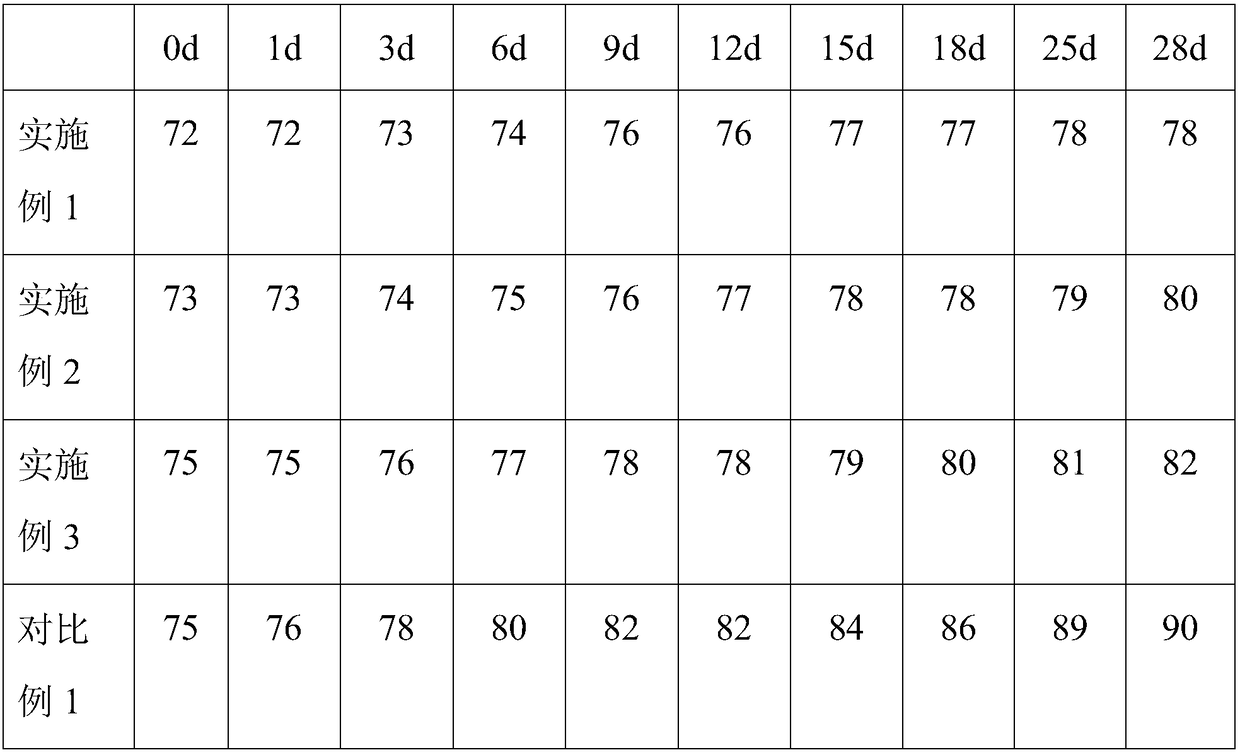

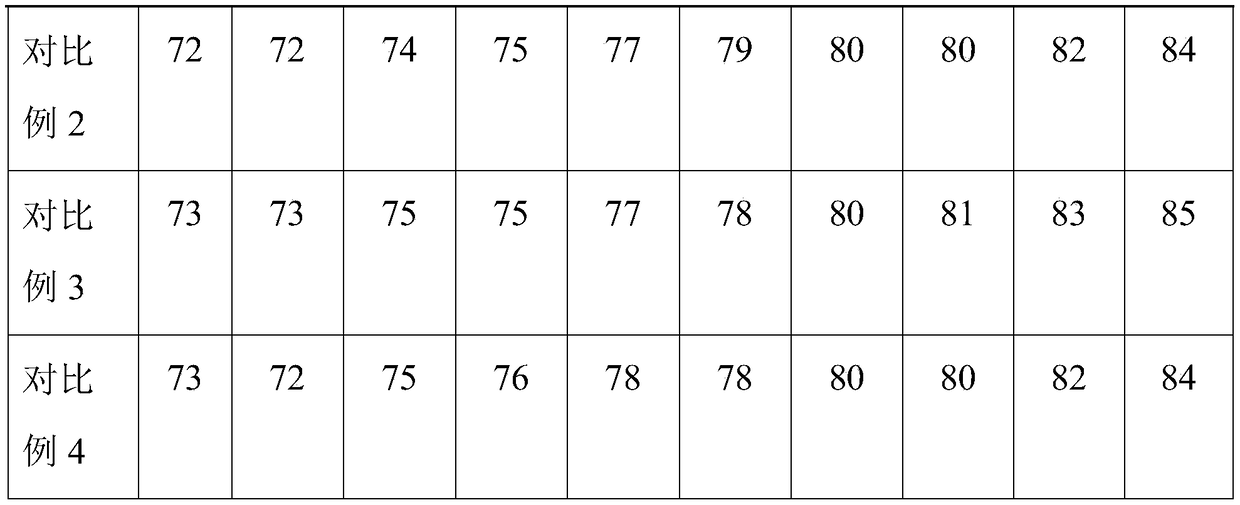

Embodiment 1

[0045]This embodiment specifically discloses a yogurt product prepared by using the method of controlling the post-acidity of yogurt according to the present invention. The yogurt is made of the following raw materials in mass percentages: white granulated sugar 7.2%; whey protein powder 1%; cream 2%; Sweetened condensed milk 0.2%, starch 0.2%, Lactobacillus bulgaricus 0.01%; Streptococcus thermophilus 0.015%; the balance is raw milk. Its concrete preparation steps are as follows:

[0046] A. Preparation of product base materials

[0047] According to the raw material formula of fermented milk, take the raw milk with the corresponding mass ratio, and after the raw milk is checked and accepted according to GB19301 and "Raw Milk Inspection Regulations", then add other ingredients except fermented lactic acid bacteria according to the formula, and mix the ingredients evenly , to produce a fermented base material; wherein, the raw milk is raw milk. This step specifically include...

Embodiment 2

[0065] This embodiment specifically discloses a yogurt product prepared by using the method of controlling the post-acidity of yogurt according to the present invention. The yogurt is made of the following raw materials in mass percentages: white granulated sugar 7.3%; whey protein powder 1%; cream 2%; Sweetened condensed milk 0.2%, starch 0.2%, Lactobacillus bulgaricus 0.01%; Streptococcus thermophilus 0.015%; Lactobacillus bifidum 0.01%; the balance is raw milk. Its concrete preparation steps are as follows:

[0066] A. Preparation of product base materials

[0067] According to the raw material formula of fermented milk, take the raw milk with the corresponding mass ratio, and after the raw milk is checked and accepted according to GB19301 and "Raw Milk Inspection Regulations", then add other ingredients except fermented lactic acid bacteria according to the formula, and mix the ingredients evenly , to produce a fermented base material; wherein, the raw milk is raw milk. ...

Embodiment 3

[0085] This embodiment specifically discloses a yogurt product prepared by using the method of controlling the post-acidity of yogurt according to the present invention. The yogurt is made of the following raw materials in mass percentages: 7.5% white sugar; 1% whey protein powder; 2% cream; Sweetened condensed milk 0.2%, starch 0.2%, Lactobacillus bulgaricus 0.01%; Streptococcus thermophilus 0.015%; Lactobacillus acidophilus 0.01%; the balance is raw milk. Its concrete preparation steps are as follows:

[0086] A. Preparation of product base materials

[0087] According to the raw material formula of fermented milk, take the raw milk with the corresponding mass ratio, and after the raw milk is checked and accepted according to GB19301 and "Raw Milk Inspection Regulations", then add other ingredients except fermented lactic acid bacteria according to the formula, and mix the ingredients evenly , to produce a fermented base material; wherein, the raw milk is raw milk. This st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com