Efficient preparation method and application of aerogel

An airgel and high-efficiency technology, applied in chemical instruments and methods, silica, inorganic chemistry, etc., can solve the problems of unsatisfactory product drying process, long production cycle, complicated process, etc., and achieve the reduction of chemical waste gas pollution , short production cycle and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

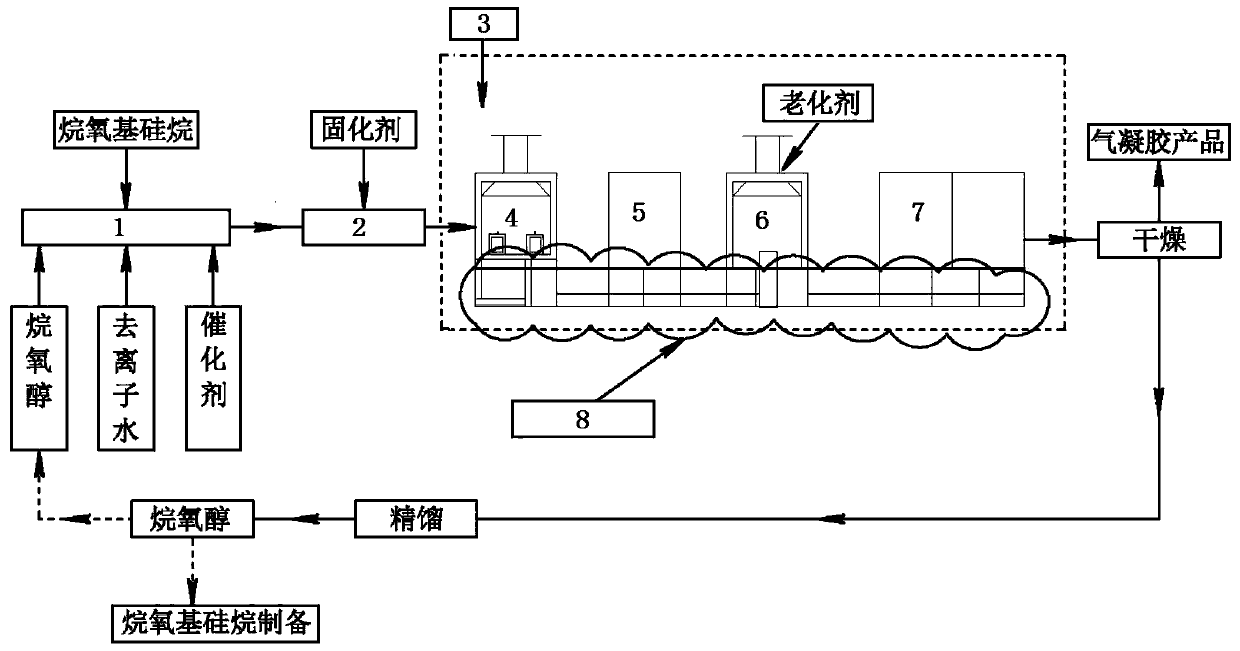

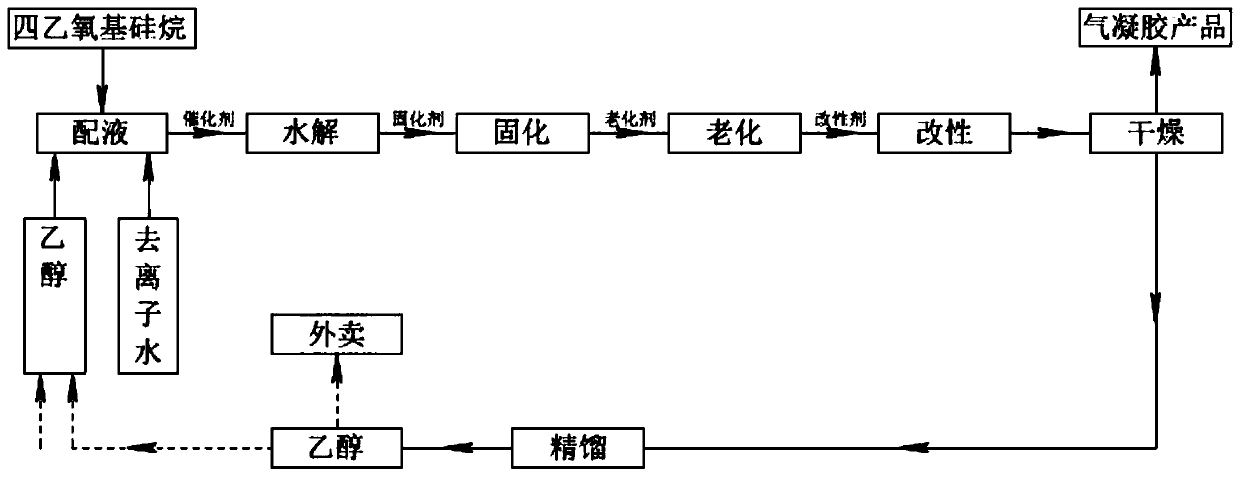

[0041] Such as figure 1 A high-efficiency preparation method of an airgel shown, comprising the following steps:

[0042] a. Add alkoxysilane, alkoxy alcohol, deionized water and acidic catalyst to reactor 1 to prepare mixed solution, and obtain silica sol after hydrolysis in reactor 1;

[0043] b. The silica sol is transported to the material mixer 2, and at the same time, a curing agent is added to the material mixer 2, and the mixture is uniformly mixed to obtain a mixed material;

[0044] c. The mixed material is transported to the glue spray cabin 4 in the airgel intelligent production integrated system 3. The airgel intelligent production integrated system 3 also includes a heating insulation cover I5, a liquid spray cabin 6, a heating insulation cover II7, and glue spraying Cabin 4, heating and heat preservation cover I5, liquid spraying cabin 6, and heating and heat preservation cover II7 are connected through a transmission device 8; the mixed material is sprayed in...

Embodiment 1

[0063] Add tetraethoxysilane, ethanol, deionized water and hydrochloric acid to Reactor 1 to prepare a mixed solution. The molar ratio between tetraethoxysilane, ethanol, deionized water and hydrochloric acid is 1:12:4: 0.001, the temperature of reactor 1 is controlled to be 90°C; tetraethoxysilane is hydrolyzed in reactor 1 for 10 minutes, and after completion, it is transported to material mixer 2, and at the same time, curing agent ammonia water is added to material mixer 2 to obtain The homogeneous mixture of silica sol and curing agent ammonia water; then it is quickly transported to the glue spray cabin 4 in the airgel intelligent production integrated system 3, and the mixed material is sprayed into the forming mold, and the forming mold and the mixed material inside are transported to the In the heating and heat preservation cover I5, control the temperature in the heating and heat preservation cover I5 to 60°C, keep the temperature for 5 minutes, and realize the curing...

Embodiment 2

[0066] Trimethoxysilane, methanol, deionized water and CH 3 COOH was added to Reactor 1 to prepare a mixed solution, trimethoxysilane, methanol, deionized water and CH 3 The molar ratio between COOH is 1:30:18:0.01, and the temperature of reactor 1 is controlled at 50°C; trimethoxysilane is hydrolyzed in reactor 1 for 20 minutes, and is transported to material mixer 2 after hydrolysis is completed. , add the curing agent KOH into the material mixer 2, and then quickly transport it to the glue spray cabin 4 in the airgel intelligent production integrated system 3, spray the mixed material into the forming mold, and the forming mold is transported with the mixed material inside Go to the heating and heat preservation cover I5, control the temperature in the heating and heat preservation cover I5 to 50°C, keep it warm for 30 minutes, and realize the curing of the silica sol under heating conditions to obtain a gel; after curing, the forming mold and the mixed material inside are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com