Conveying belt deflection mechanism, conveying belt gypsum product molding device and production line

A conveyor belt and deflection correction technology, which is applied to conveyors, forming conveyors, transportation and packaging, etc., can solve the problems of high labor intensity for operators, occupy a large space, and low production efficiency, and achieve improved quality and appearance. The effect of high production efficiency and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

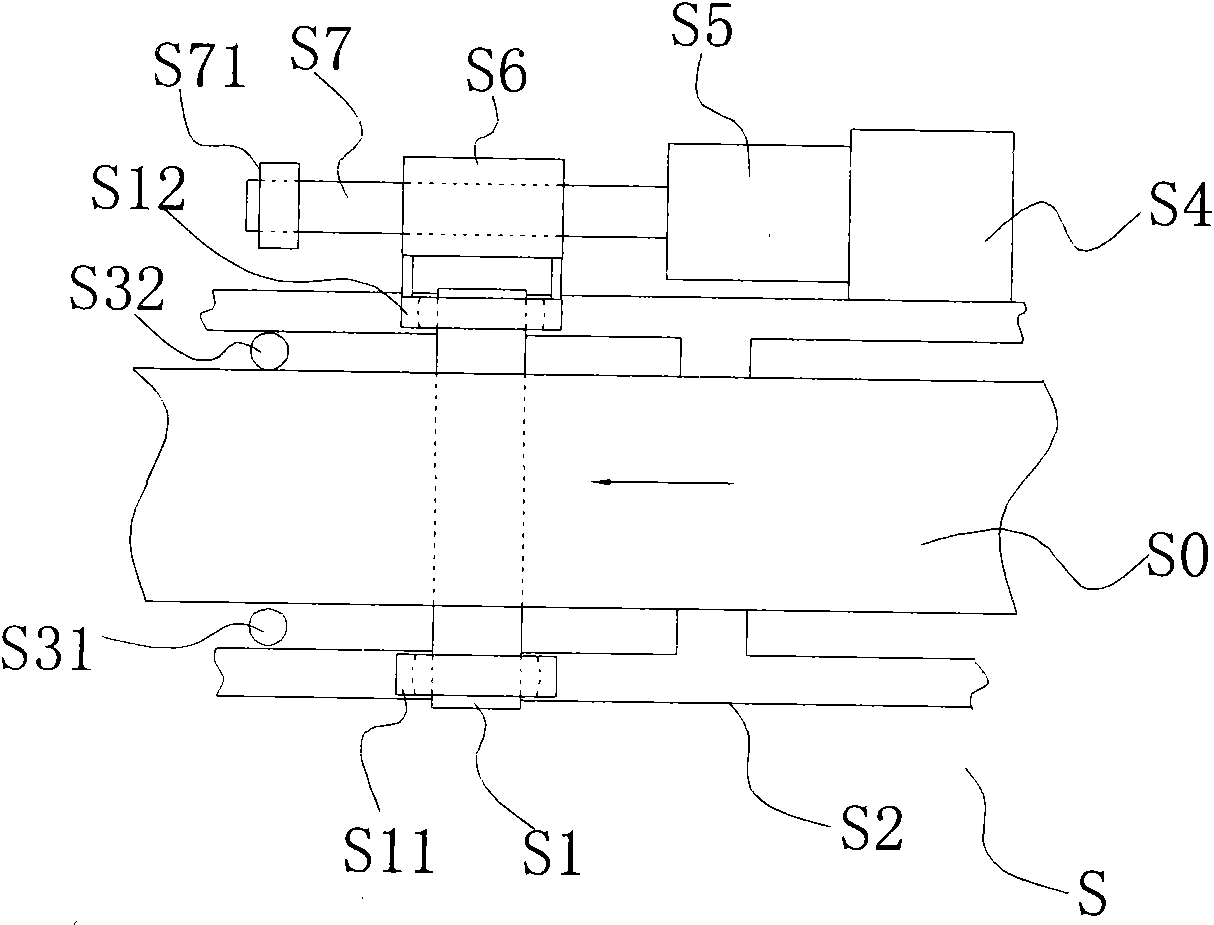

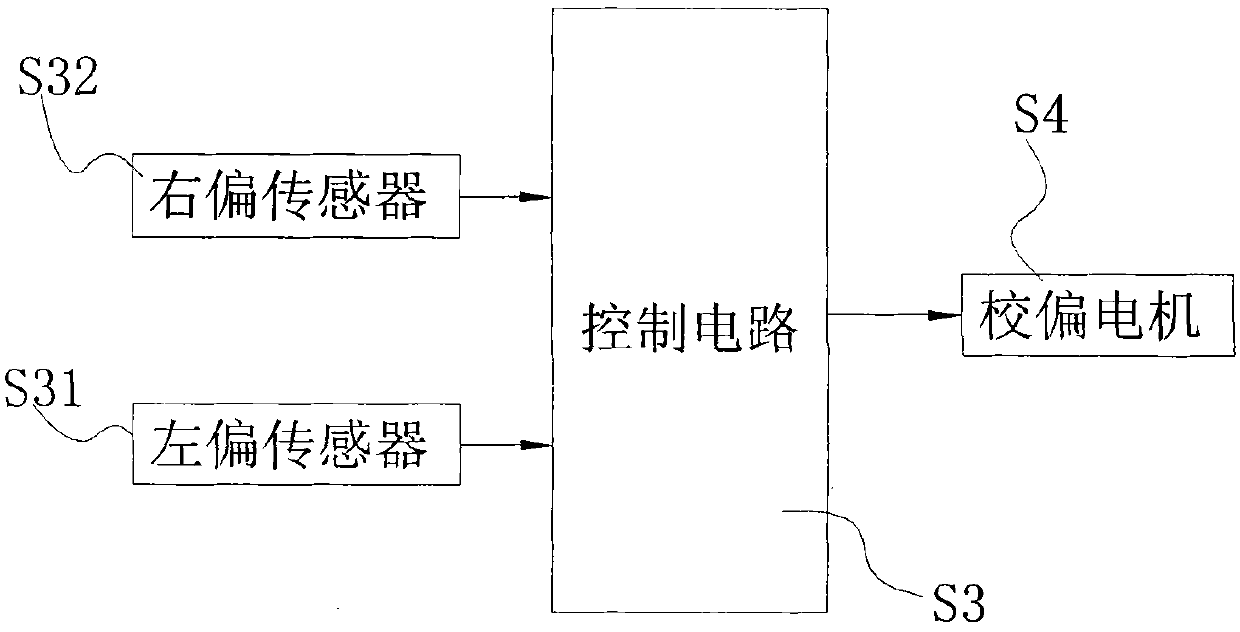

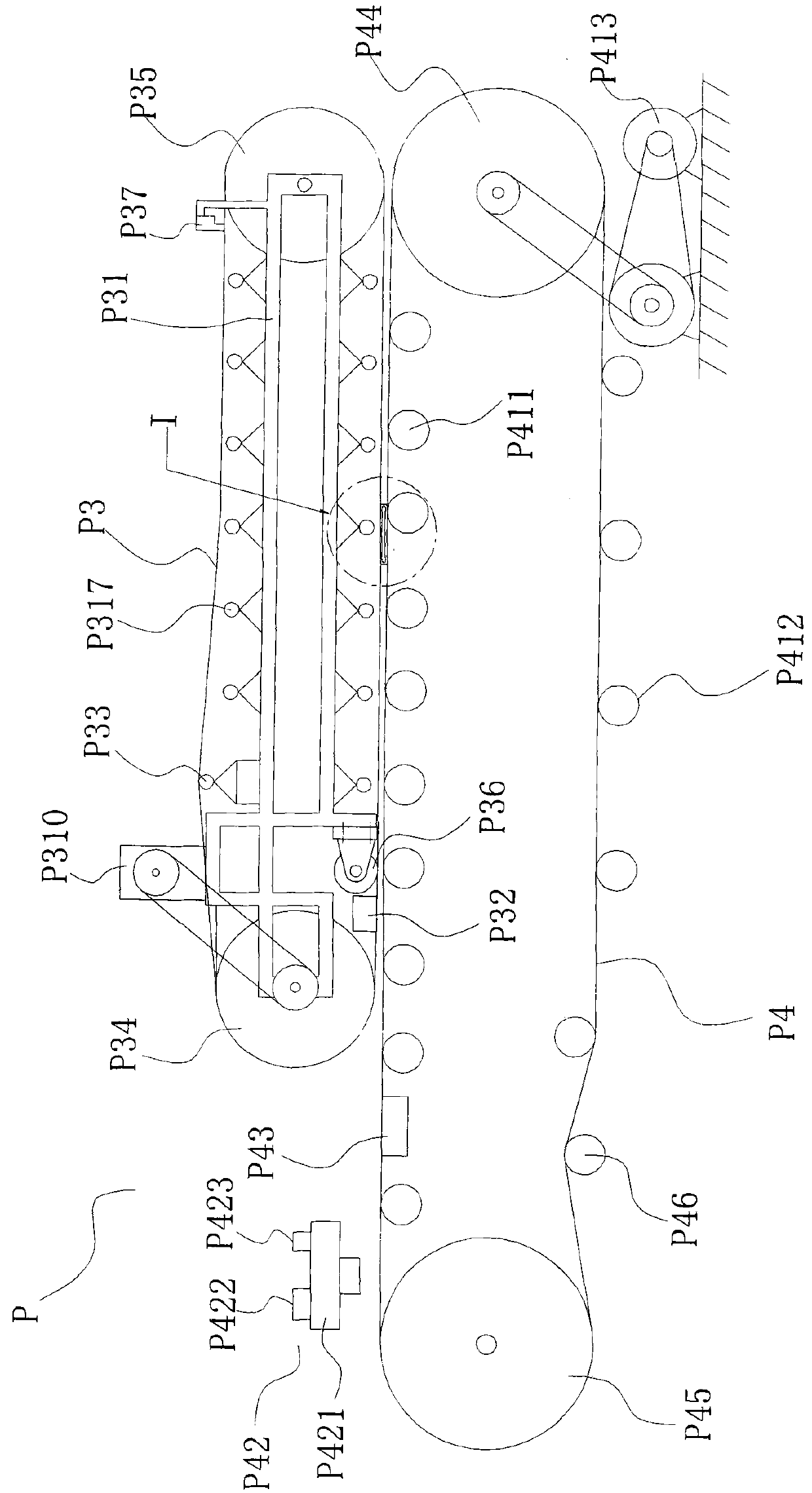

[0099] Such as Figure 1A to Figure 1B As shown, a conveyor belt deflection correction mechanism S of the present invention includes a deflection correction roller S1 for tensioning the conveyor belt S0. The deflection correction roller S1 is fixed on the frame S2, and also includes a control circuit S3 and is connected to the control circuit S3. The left deviation sensor S31, the right deviation sensor S32, the left deviation sensor S31, the right deviation sensor S32 (using a photoelectric switch, output a detection signal when an object approaches) are respectively located on the left outer side and the right outer side of the conveyor belt S0; The deviation correction motor S4 electrically connected with the circuit S3, the devia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com