Three-dimensional curved surface roll forming device

A technology of roll forming and three-dimensional curved surface, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large manpower, material resources and time consumption, poor forming quality, small torque, etc., and achieve manpower saving and continuous forming , Increase the effect of the transmitted torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

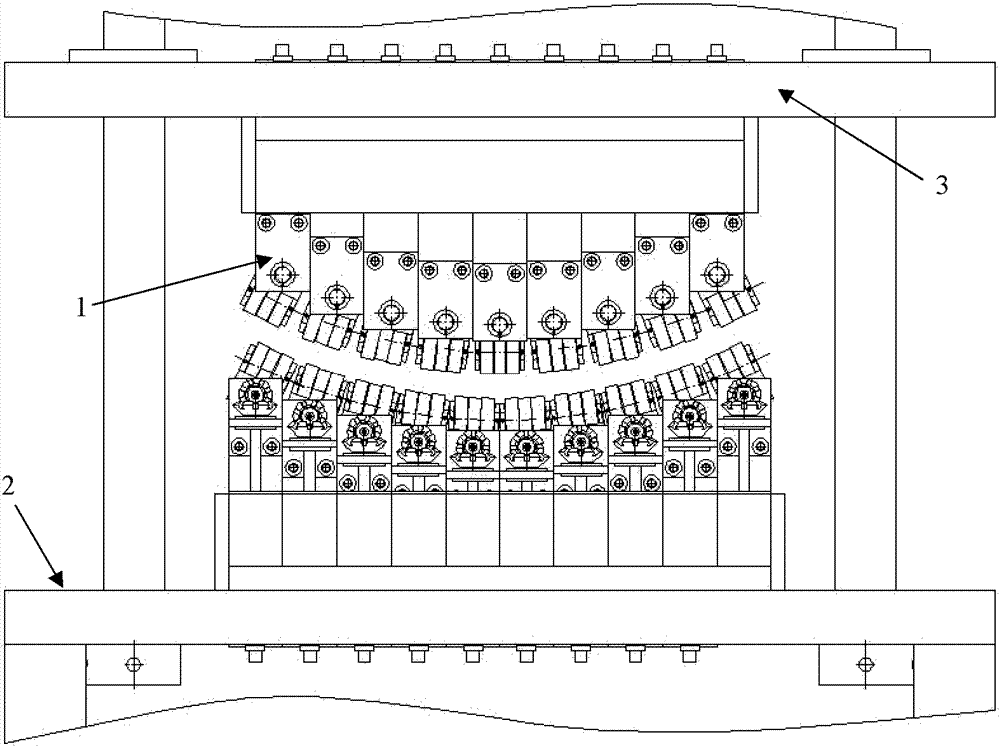

[0027] figure 1 It is a schematic diagram of the core part of the three-dimensional curved surface roll forming device. A row of 9 rolling units 1 is arranged in the upper part of the figure, and two rows of 10 rolling units 1 are arranged in parallel in the lower part. Of course, two or more rows of rolling units 1 can be arranged in the upper part; the number of rows of rolling units 1 arranged in the lower part is usually one row more than that in the upper part. According to the shape of the three-dimensional curved surface to be processed, first, adjust the height of the work rolls 9 in each rolling unit 1 by computer or manually, so that the work rolls 9 are arranged into the required curve; secondly, by adjusting the height of the movable beam 3 A certain amount of pressing is generated, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com