Continuous feeding laser welding machine for super capacitor

A laser welding machine, super capacitor technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of reducing the working efficiency of laser welding machine, unable to weld welding parts, etc., to achieve continuous production and processing, improve work efficiency The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

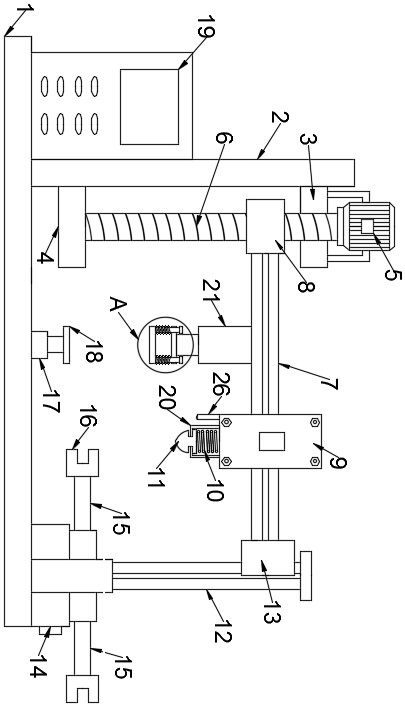

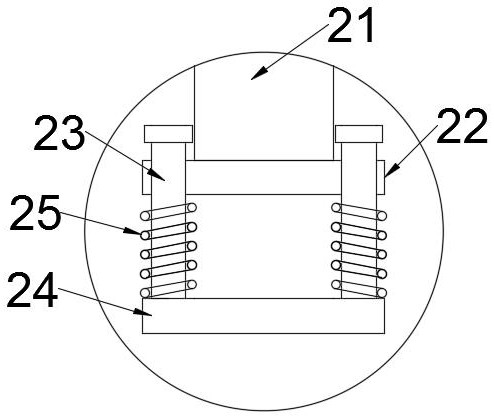

[0021] Embodiment 1: When in use, the external power supply is connected and controlled by the control box 19. The operator fixes the weldment to be processed through the clamp 16, and the rotary table 14 rotates to transfer the weldment to be processed to the bottom of the laser welding head 11, and the hydraulic telescopic The cylinder 17 makes the support plate 18 rise to touch the weldment. At the laser welding head 11, the pressure plate 24 presses and fixes the fixture 16. The laser welding head 11 starts welding. After the processing is completed, the pressure plate 24 moves up and the support plate 18 moves down to loosen. When the weldment is opened, the rotary table 14 rotates to move the next weldment to be processed under the laser welding head 11 for welding again. During this process, the operator removes the processed weldment and replaces it with a new one to be welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com