Antibacterial and bacteria-isolation SMMS composite non-woven fabric

A technology of non-woven fabrics and spun-bonded non-woven fabrics, which is applied in the direction of textiles and papermaking, synthetic resin layered products, fire-resistant and flame-retardant filaments, etc. It can solve the problems of poor air permeability, bacterial resistance, and waterproof penetration To improve the breaking strength and elongation at break, improve the antibacterial ability, and improve the anti-seepage and isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

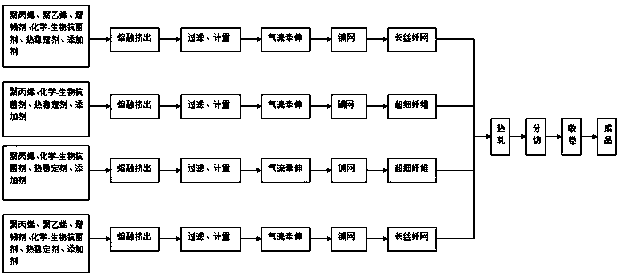

Method used

Image

Examples

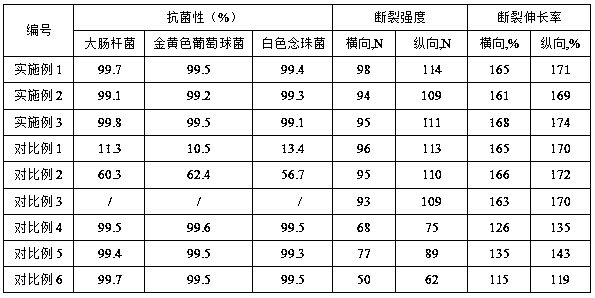

Embodiment 1

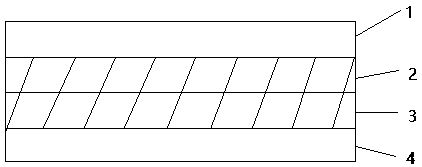

[0042] An antibacterial bacteria-retaining SMMS composite nonwoven fabric, comprising a first spunbonded nonwoven fabric layer, a first meltblown layer, a second meltblown layer, and a second spunbonded nonwoven fabric layer. The first spunbonded nonwoven fabric The cloth layer and the second spunbonded non-woven fabric layer are an upper surface layer and a lower layer, respectively, and the first meltblown layer and the second meltblown layer are intermediate layers.

[0043] Both the first spunbond non-woven fabric layer and the second spunbonded non-woven fabric layer include the following components by mass:

[0044] Polypropylene (melt index is 35g / 10min) 99

[0045] Polyethylene 1

[0046] Polyolefin elastomer 0.5

[0047] Polyhexamethyleneguanidine hydrochloride 0.5

[0048] γ-polyglutamic acid 0.5

[0049] Phenolic heat stabilizer 1010 0.5

[0050] Masterbatch 1

[0051] Ammonium polyphosphate flame retardant 1

[0052] Both the first meltblown layer and the second meltblown layer ...

Embodiment 2

[0064] An antibacterial bacteria-retaining SMMS composite nonwoven fabric, comprising a first spunbonded nonwoven fabric layer, a first meltblown layer, a second meltblown layer, and a second spunbonded nonwoven fabric layer. The first spunbonded nonwoven fabric The cloth layer and the second spunbonded non-woven fabric layer are an upper surface layer and a lower layer, respectively, and the first meltblown layer and the second meltblown layer are intermediate layers.

[0065] Both the first spunbond non-woven fabric layer and the second spunbonded non-woven fabric layer include the following components by mass:

[0066] Polypropylene (melt index is 35g / 10min) 99

[0067] Polyethylene 1

[0068] Polyolefin elastomer 0.5

[0069] Polyhexamethyleneguanidine phosphate 0.5

[0070] γ-polyglutamic acid 0.5

[0071] Phenolic heat stabilizer 1010 0.5

[0072] Masterbatch 1

[0073] Ammonium polyphosphate melamine flame retardant 1

[0074] Both the first meltblown layer and the second meltblown l...

Embodiment 3

[0086] An antibacterial bacteria-retaining SMMS composite nonwoven fabric, comprising a first spunbonded nonwoven fabric layer, a first meltblown layer, a second meltblown layer, and a second spunbonded nonwoven fabric layer. The first spunbonded nonwoven fabric The cloth layer and the second spunbonded non-woven fabric layer are an upper surface layer and a lower layer, respectively, and the first meltblown layer and the second meltblown layer are intermediate layers.

[0087] Both the first spunbond non-woven fabric layer and the second spunbonded non-woven fabric layer include the following components by mass:

[0088] Polypropylene (melt index is 35g / 10min) 99

[0089] Polyethylene 1

[0090] Polyolefin elastomer 0.5

[0091] Polyhexamethyleneguanidine hydrochloride 0.5

[0092] γ-polyglutamic acid 0.5

[0093] Thioester heat stabilizer 412S 0.5

[0094] Masterbatch 1

[0095] Ammonium polyphosphate flame retardant 1

[0096] Both the first meltblown layer and the second meltblown layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com