Thermochromic indicator for reagent gas vessel

An indicator and thermal discoloration technology, applied in the direction of container discharge, gas treatment/storage purpose, installation device of container structure, etc., can solve problems such as damage to equipment or manufactured items, loss of time and productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

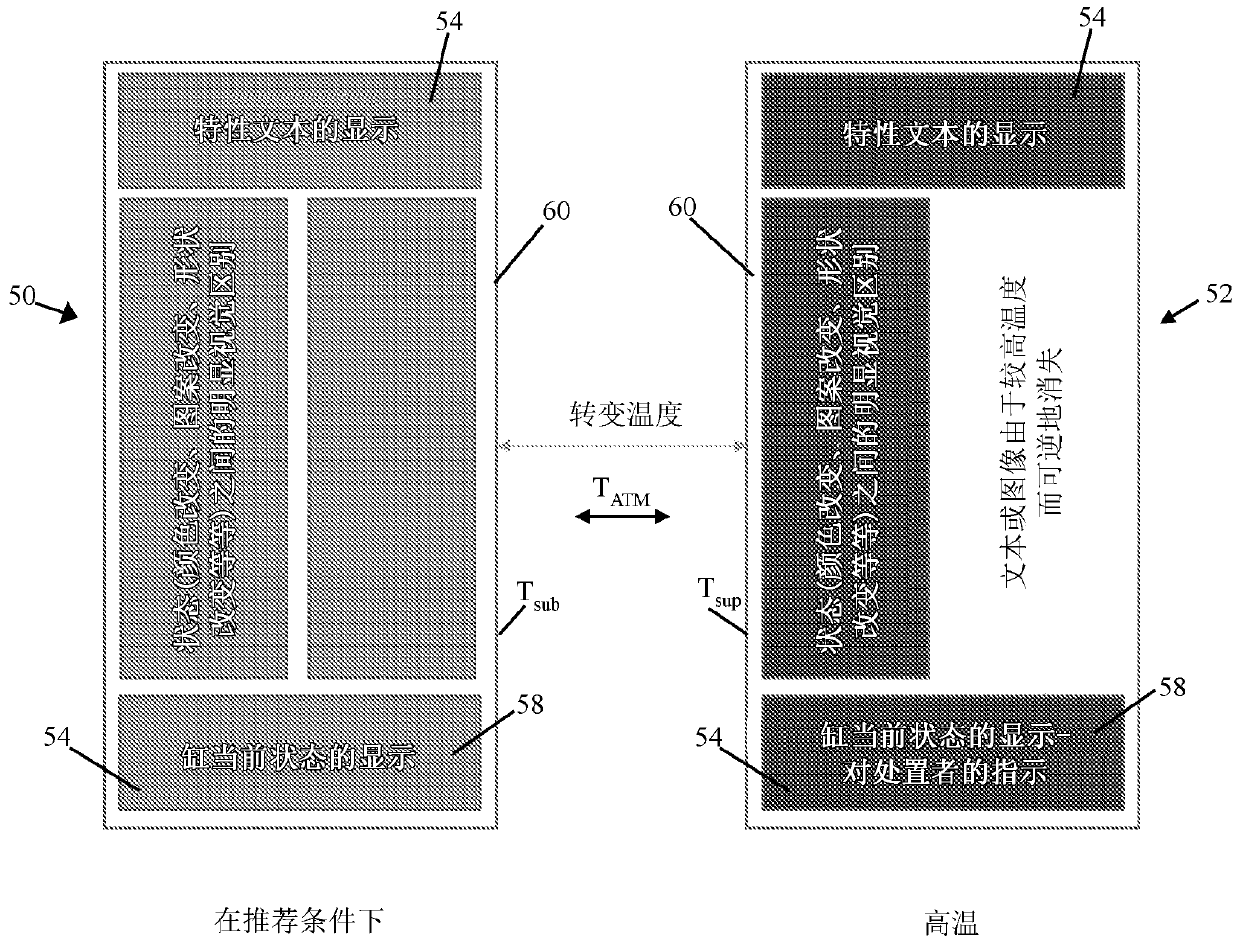

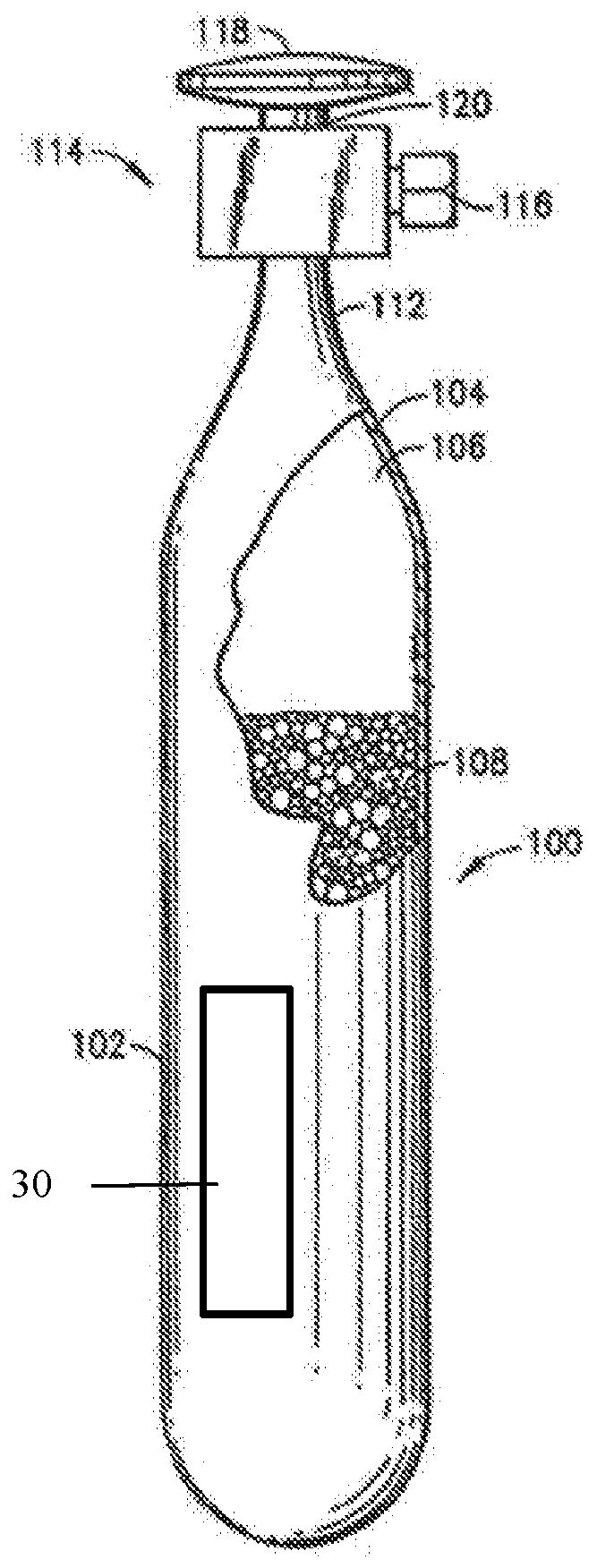

[0031] The present description relates to novel storage containers and methods of use thereof. The container contains a thermochromic indicator effective to communicate information about the pressure of the gaseous contents within the container to a location external to the container. Thermochromic indicators can be used in methods for handling, storing, using, and supplying gases (e.g., hazardous reagent gases) by using a change in appearance to identify whether the pressure of the gas stored in the container exceeds a predetermined maximum pressure, so Said gas is stored by the container with an increased level of safety.

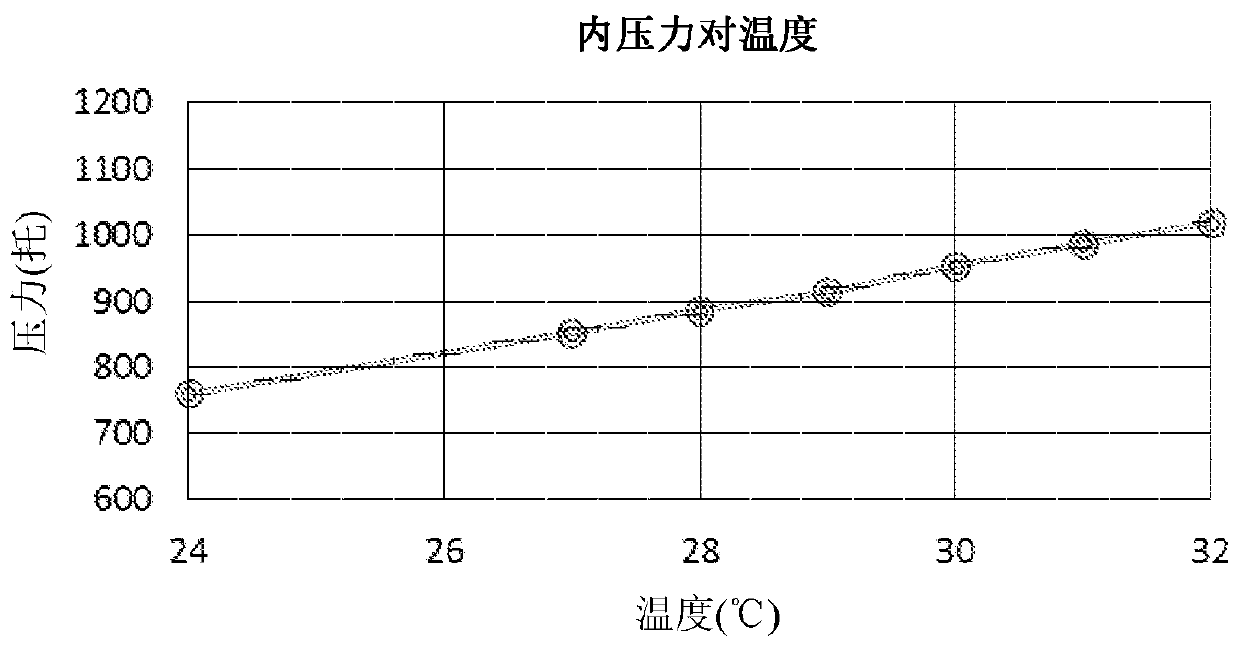

[0032] Gases stored by storage and delivery containers may desirably be stored in said containers, wherein said gas is present at a pressure below a predetermined desired maximum pressure. A predetermined desired maximum pressure is understood to occur at a particular temperature (which may be referred to herein as a "transition temperature", see above)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com