Polyamide material for improving adhesion effect of paint as well as preparation method and application of polyamide material

A polyamide and coating technology, which is applied in the field of polyamide materials and their preparation for improving the adhesion effect of coatings, can solve the problems of poor adhesion effect of coatings, poor fluidity, poor adhesion of coatings in wet and dry states, etc. The effect of maintaining fluidity, enhancing wetting and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0041] (1) Put semi-crystalline polyamide, ionic polymer, plasticizer, lubricant, long-term thermal aging resistance agent and antioxidant into a low-speed mixer, mix at a speed of 100r / min for 5min, and mix well to form the main ingredient ,spare;

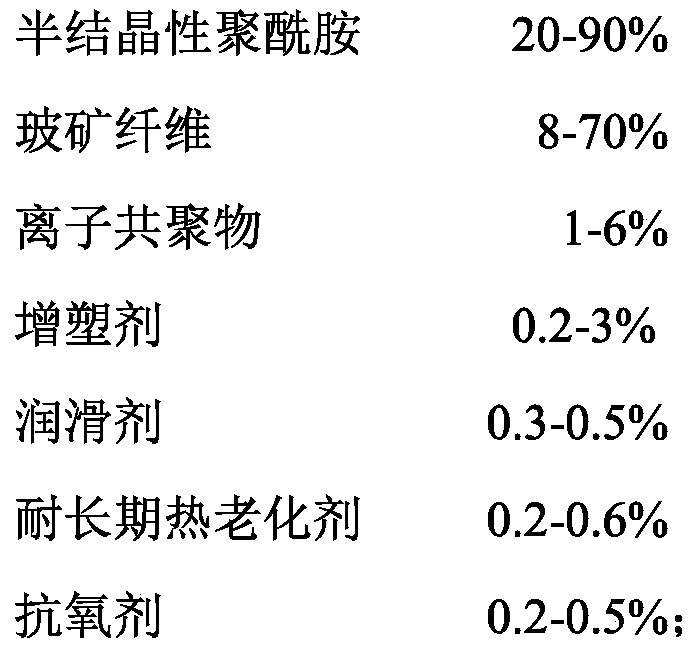

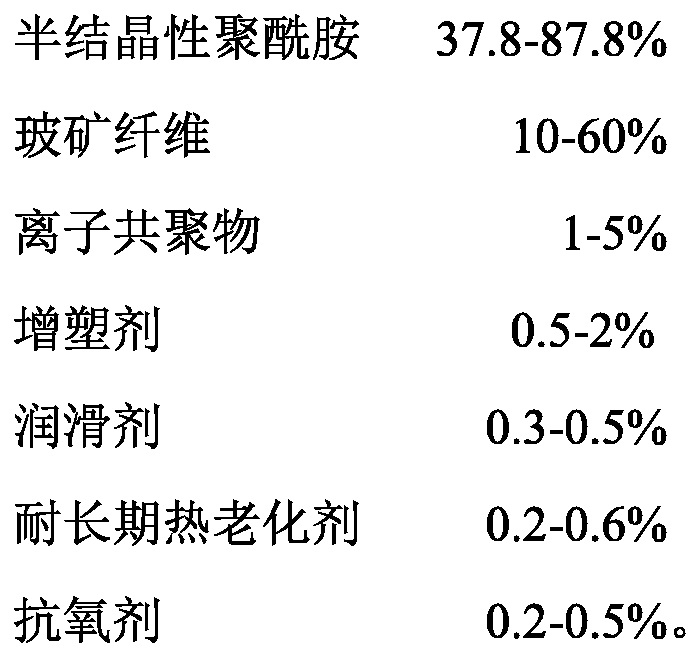

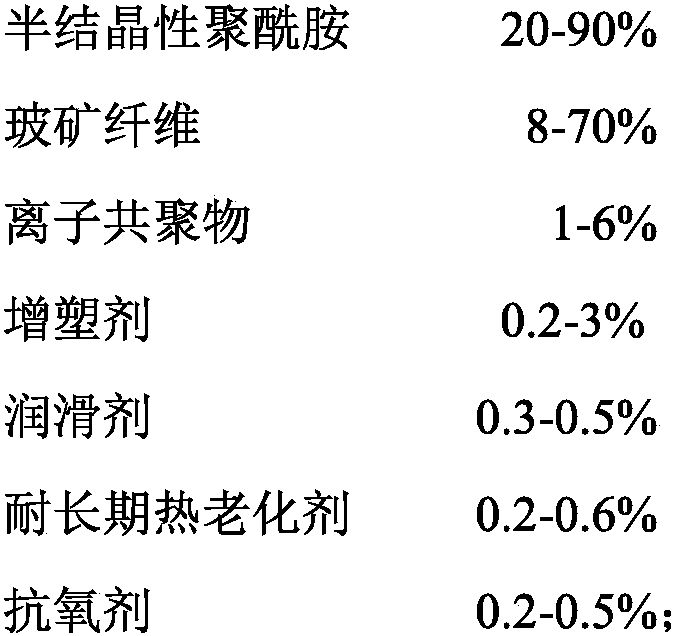

[0042](2) The above-mentioned main material is metered and fed through the loss-in-weight scale from the main feed port of the twin-screw extruder, and the chopped glass fiber is metered and fed through the weight-loss scale from the side feed port of the twin-screw extruder; The temperature of each section of the screw extruder is: 230°C, 265°C, 270°C, 270°C, 265°C, 255°C, 255°C, 245°C, 245°C, 245°C, the head temperature is 270°C, the screw speed The speed is 400r / min; the material is fully fused under the shearing, mixing and conveying of the screw, and finally it is extruded, drawn, cooled by water, and pelletized to make polyamide material pellets to improve the coating adhesion effect. Wherein, the consumption of each compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com