Method for recovering and utilizing metal resources by using Bacillus extracellular polymer

A technology of bacillus and heavy metals, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems that cannot be realized, and achieve the reduction of harm, increase of production efficiency, and simple extraction method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Bacillus megaterium was used as the bacillus in this embodiment.

[0044]The EPS of Bacillus megaterium is prepared by the following steps:

[0045] (1) Adjust the pH value of the Luria-Bertani liquid medium to 7-8, place it at a temperature of 100-121°C for 30-40 minutes and then prepare it as a Luria-Bertani liquid fermentation medium, using solid Luria-Bertani Culture medium, after activating and culturing Bacillus megaterium for 24-36 hours, inoculate it into Luria-Bertani liquid fermentation medium, and culture it at 23-25°C for 24-36 hours to obtain a microbial fermentation broth made of Bacillus megaterium;

[0046] In the aforementioned steps, the choice of pH value and fermentation temperature provides the best environment for the fermentation of Bacillus megaterium to produce a large amount of beneficial ingredients.

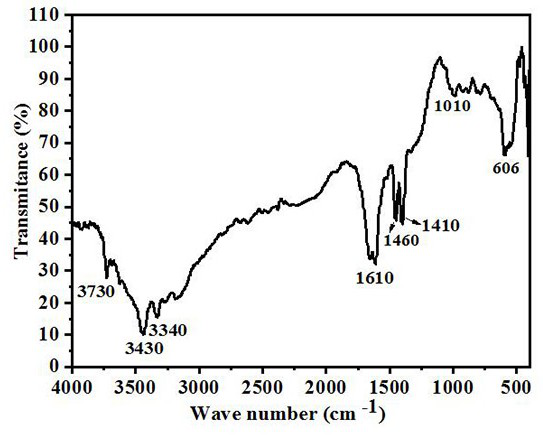

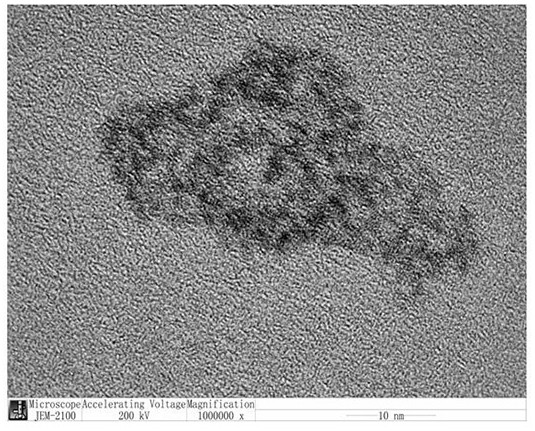

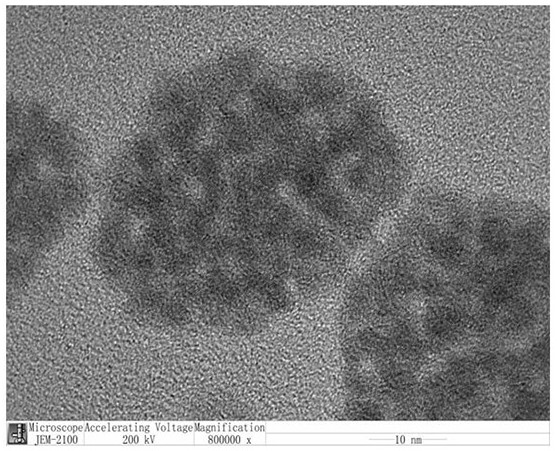

[0047] (2) Centrifuge the microbial fermentation liquid in step (1) at 5-7°C and 3000-8000r / min, let it stand after centrifugation, take the s...

Embodiment 2

[0069] In this example, Bacillus subtilis was used as the microorganism belonging to the genus Bacillus.

[0070] The EPS of Bacillus subtilis is prepared by the following steps:

[0071] (1) Adjust the pH value of the Luria-Bertani liquid medium to 7-8, place it at a temperature of 100-121°C for 30-40 minutes and then prepare it as a Luria-Bertani liquid fermentation medium, using solid Luria-Bertani Culture medium, after activating and culturing Bacillus subtilis for 26 hours, inoculate it into Luria-Bertani liquid fermentation medium, and culture it at 23-25°C for 24-36 hours to obtain a microbial fermentation broth made of Bacillus subtilis;

[0072] In the aforementioned steps, the choice of pH value and fermentation temperature provides the best environment for the fermentation of Bacillus subtilis to produce a large amount of beneficial ingredients.

[0073] (2) Centrifuge the microbial fermentation liquid in step (1) at 5-7°C and 3000-8000r / min, let it stand after cen...

Embodiment 3

[0095] In this example, Bacillus genus microorganisms adopt Bacillus cereus

[0096] The EPS of Bacillus cereus is prepared by the following steps:

[0097] (1) Adjust the pH value of the Luria-Bertani liquid medium to 7-8, place it at a temperature of 100-121°C for 30-40 minutes and then prepare it as a Luria-Bertani liquid fermentation medium, using solid Luria-Bertani Culture medium, after activating and culturing Bacillus cereus for 24-48 hours, inoculate it into Luria-Bertani liquid fermentation medium, and culture it at 23-25°C for 24-36 hours to obtain a microbial fermentation broth made of Bacillus cereus;

[0098] In the aforementioned steps, the choice of pH value and fermentation temperature provides the best environment for the fermentation of Bacillus cereus to produce a large amount of beneficial ingredients.

[0099] (2) Centrifuge the microbial fermentation liquid in step (1) at 5-7°C and 3000-8000r / min, let it stand after centrifugation, take the supernatant,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com