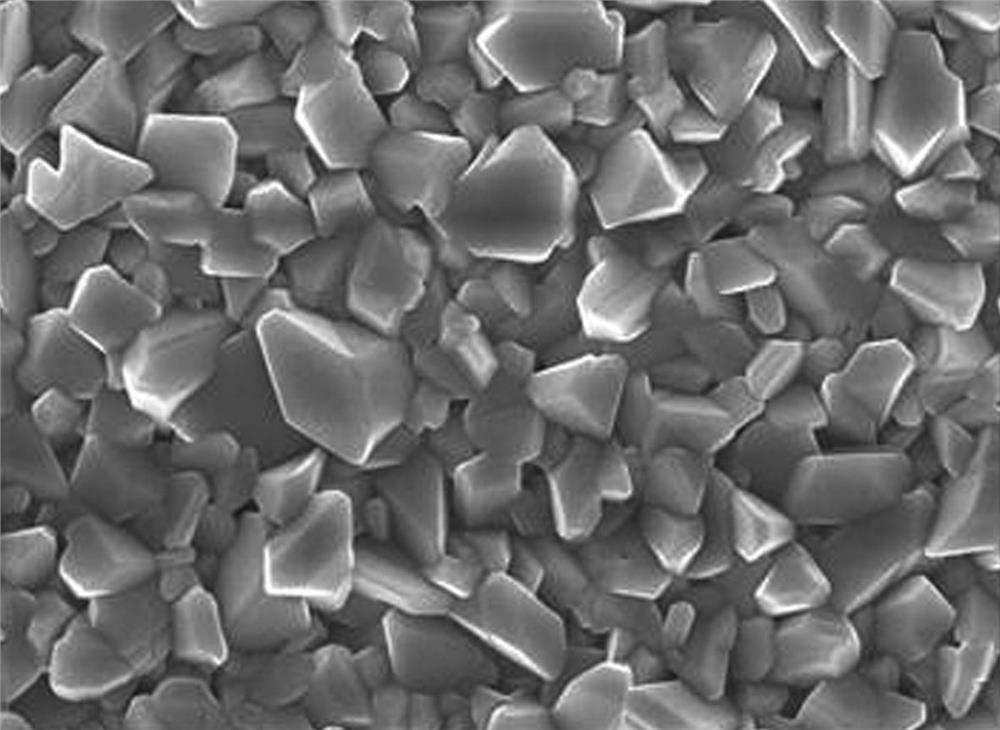

A method to improve the efficiency of flexible copper indium gallium selenide thin film solar cells

A solar cell and copper indium gallium selenide technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of harsh preparation conditions, high cost, and low photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

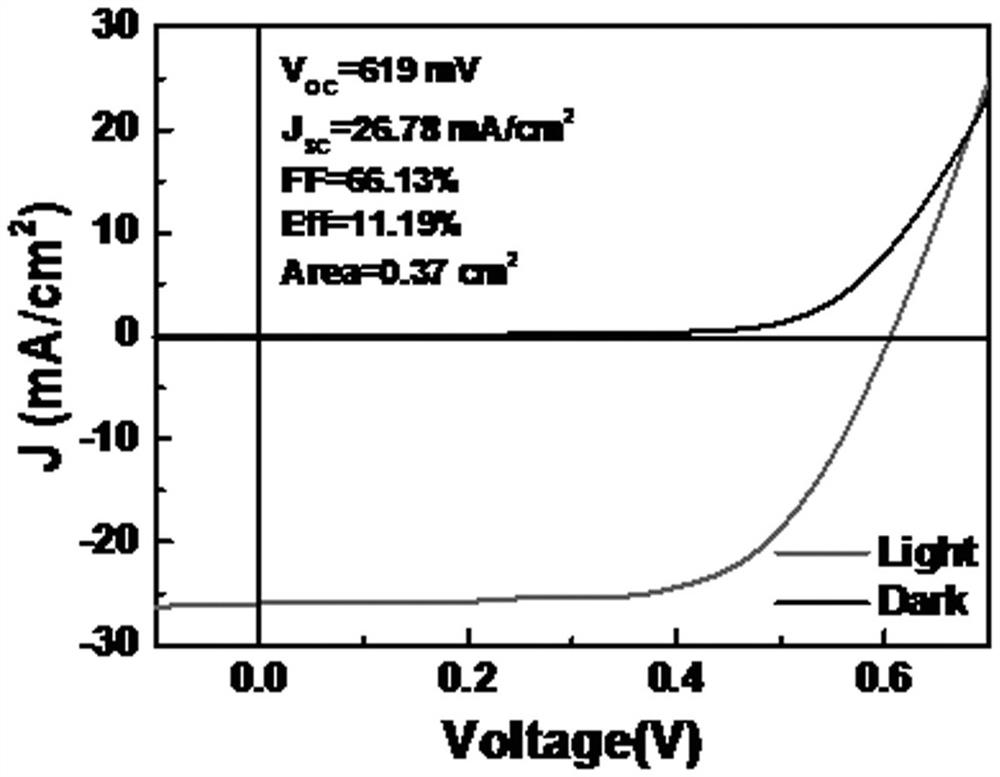

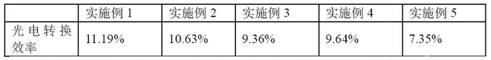

Examples

Embodiment 1

[0030] Step A. Sputter molybdenum electrodes on a clean polyimide / stainless steel substrate: when the pressure of argon gas reaches 2Pa, turn on the DC sputtering power supply, adjust the power to 200W, pre-sputter for 5 minutes, and then remove the metal The baffle was sputtered on the substrate for 30 minutes, then the argon pressure in the cavity was adjusted to 1 Pa, the sputtering was performed for 30 minutes, and the power was turned off to obtain a molybdenum electrode with good density and bonding force.

[0031] Step B. Preparation of CIGSe precursor solution: First, weigh copper powder (0.0699g, 1.10mmol), indium powder (0.0960g, 0.83mmol), gallium powder (0.0250g, 0.35mmol), selenium powder (0.1812g, 2.29 mmol), bismuth chloride powder (0.0104g, 0.0456mmol) and potassium chloride powder (0.0034g, 0.0456mmol) were added to a 25mL Erlenmeyer flask; then 5mL of ethylenediamine and 5mL of ethanedithiol were added. Finally, the round-bottomed flask was sealed and placed ...

Embodiment 2

[0041] Step A. Sputter molybdenum electrodes on a clean polyimide / stainless steel substrate: when the pressure of argon gas reaches 3Pa, turn on the DC sputtering power supply, adjust the power to 250W, pre-sputter for 5 minutes, and then remove the metal The baffle is sputtered on the substrate for 60 minutes, and then the argon pressure in the cavity is adjusted to 0.1 Pa, the sputtering is performed for 60 minutes, the power is turned off, and a molybdenum electrode with good density and bonding force is obtained.

[0042] Step B. Preparation of CIGSe precursor solution: First, weigh copper nitrate (0.206g, 1.10mmol), indium nitrate (0.250g, 0.83mmol), gallium nitrate (0.0895g, 0.35mmol), selenium dioxide (0.2541g, 2.29mmol), bismuth nitrate powder (0.193g, 0.4mmol) and potassium hydroxide powder (0.0228g, 0.4mmol) were added to a 25mL conical flask; then 5mL ethylenediamine and 5mL ethanedithiol were added. Finally, the round-bottomed flask was sealed and placed on a heati...

Embodiment 3

[0050] The steps in this example are roughly similar to those in Example 1, and the similarities will not be repeated. The difference is that no bismuth chloride powder is added in step B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com