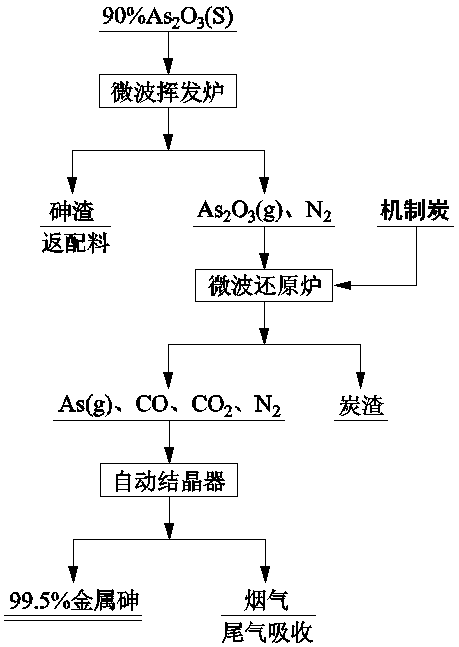

Technology and device for preparing metal arsenic from crude white arsenic

A metal arsenic and coarse white technology, which is applied in the process and equipment field of preparing metal arsenic from crude white arsenic, can solve the problems of poor working environment, high labor intensity, high production cost, etc., to reduce production cost, prolong the life of the furnace, Effect of preventing oxidation of metal arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The following elements are taken as an example for crude white arsenic, and the content of the elements is shown in Table 1:

[0024]

[0025] Take the following process steps:

[0026] a. Microwave distillation:

[0027] When the volatile section of the microwave distillation furnace has reached 660°C in advance, the outlet pressure of the distillation furnace is -5Pa, and the nitrogen flow through the feeding port and slag discharge port is controlled at 0.6L / min, 240kg of crude white arsenic (containing As 2 o 3 92%) is spread on the transmission chain plate of the distillation furnace through the feeding auger, and the coarse white arsenic enters the volatilization area along with the chain plate transmission, and the As in the coarse white arsenic 2 o 3 Gradually volatilize and enter the reduction furnace in gaseous form; after volatilization, the residual arsenic slag reaches the slag discharge section at the furnace tail, is cooled by a water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com