Preparation method and application of a composite biomass airgel photothermal conversion material

A light-to-heat conversion material and biomass material technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve problems that restrict human survival and development, by-products are harmful to the environment, and fresh water resources are limited and other problems, to achieve good light absorption performance, efficient water evaporation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Compositing of 300°C carbonized pomelo peel powder and chitosan

[0033] A preparation method of a composite biomass airgel light-to-heat conversion material, the method comprising the following steps:

[0034] 1) First put the discarded pomelo peel into a blast drying oven at a constant temperature of 60-100°C to dry, weigh 5-10 g of dried pomelo peel and place it in a vacuum tube furnace, feed nitrogen gas as a protective gas at a flow rate of 20 sccm, Carbonize the pomelo peel at 300°C, the heating rate is 1-5°C / min, and keep warm for 3-5 hours; grind the carbonized pomelo peel with an agate mortar, and sieve it with a 120-mesh (125 μm) stainless steel screen to obtain biomass carbon powder;

[0035] 2) 4.5g chitosan powder is poured in the 300ml acetic acid solution of 2wt%, is placed in the chitosan solution of the preparation 1.5wt% of magnetic stirrer stirring;

[0036] 3) Mix 0.1 g of the biomass carbon powder obtained in step 1) and the solution obt...

Embodiment 2

[0043] Referring to Example 1, the difference is that step 1) carbonization temperature is 500°C.

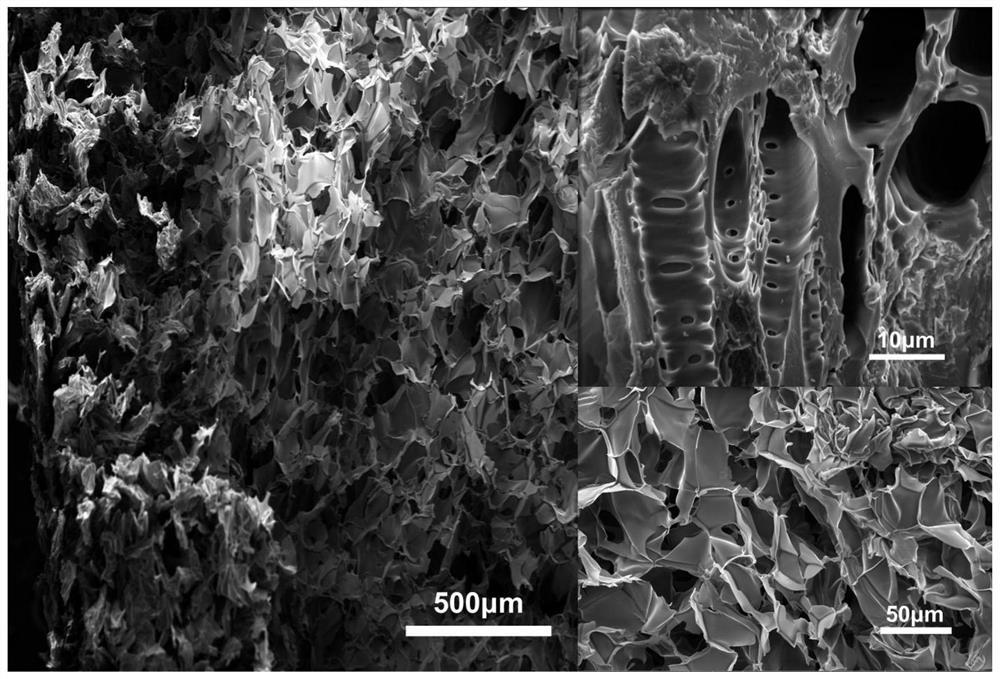

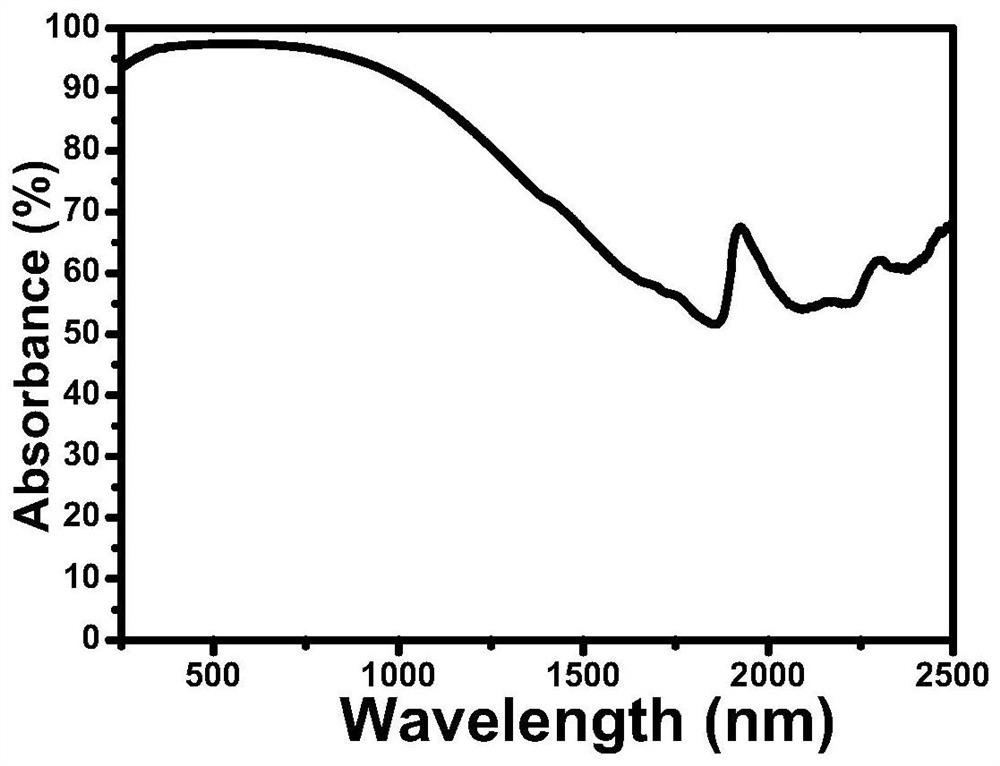

[0044] The prepared composite biomass airgel light-to-heat conversion material can see obvious layering phenomenon. The light-absorbing layer is a self-assembled porous structure and multi-level structure of disordered biomass carbonized powder, and the pores of plants are retained inside the carbon powder particles. The structure is conducive to the escape of water vapor, and the chitosan layer is an ordered three-dimensional honeycomb porous structure (such as image 3), the solar light absorption rate of the composite airgel is 96.26% in the range of 250-2500nm (such as Figure 4 shown).

Embodiment 3

[0046] Referring to Example 1, the difference is that step 1) carbonization temperature is 700°C.

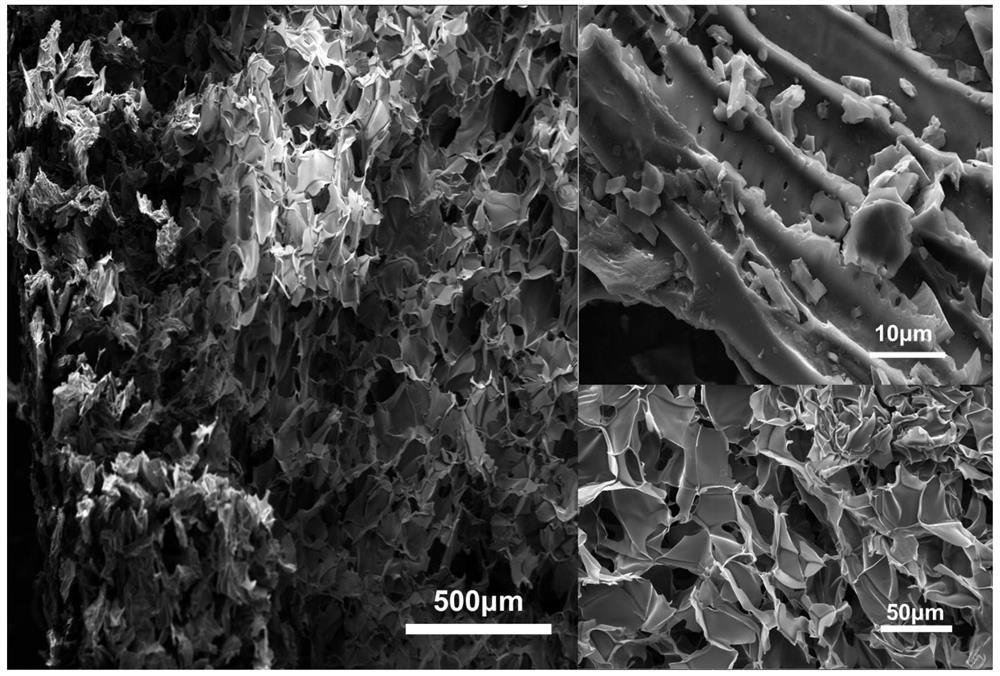

[0047] The prepared composite biomass airgel light-to-heat conversion material can be seen to have obvious layering phenomenon. The light-absorbing layer is a disordered biomass carbonized powder, and the original pipe of the plant is retained inside, which is a three-dimensional honeycomb porous structure. The layer is an ordered three-dimensional honeycomb porous structure (such as Figure 5 ), the solar light absorption rate of the composite airgel is 95.42% in the range of 250-2500nm (such as Image 6 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com