Production process of copper aluminum composite decorative material

A decorative material, copper-aluminum composite technology, applied in manufacturing tools, rolling mill control devices, metal processing equipment, etc. Low strength and other problems, to achieve the effect of improving interface bonding and electrical conductivity, beautiful appearance, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

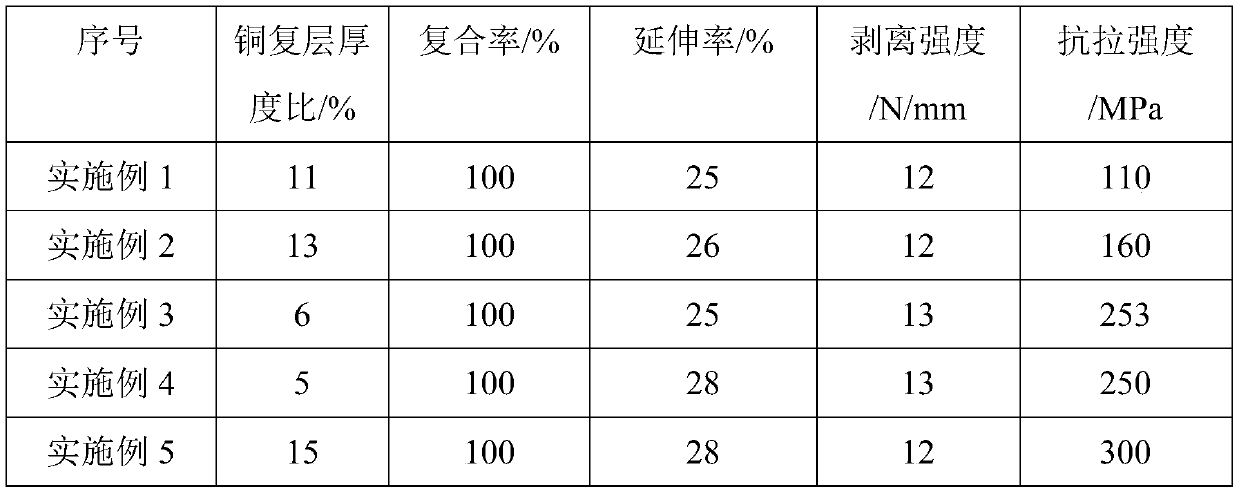

Examples

Embodiment 1

[0023] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0024] (1) One side surface of the T2 copper plate with a width of 1200mm and a thickness of 1.0mm is electroplated with tin to obtain a copper plate blank with a tin-plated layer, and the thickness of the tin-plated layer is 0.003mm; Tin sulfamate, 0.8% sulfuric acid, 0.9% AlCl 3 and 6% trisodium phosphate, the solvent is water; the temperature of electroplating tin is 200°C, the voltage is 380V, the current is 600A, and the current density is 0.5A / dm 2 ;

[0025] (2) Facing the aluminum plate with the tin-plated layer of the copper plate blank with the tin-plated layer, it is hot-rolled and compounded with 1060 aluminum plates with a thickness of 8 mm, annealed and heat-treated, and cold-rolled to obtain a copper-aluminum composite decorative material; the temperature of the hot-rolled compound is 300° C. The rolling speed of hot-roll...

Embodiment 2

[0027] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0028] (1) One side surface of the T2 copper plate with a width of 1500mm and a thickness of 1.2mm is electroplated with tin to obtain a copper plate blank with a tin-plated layer, and the thickness of the tin-plated layer is 0.010mm; Tin sulfamate, 2% sulfuric acid, 1.1% AlCl 3 and 6.5% trisodium phosphate, the solvent is water; the temperature of tin plating is 280°C, the voltage is 380V, the current is 800A, and the current density is 3.0A / dm 2 ;

[0029] (2) Facing the aluminum plate with the tin-plated layer of the copper plate blank with the tin-plated layer, hot-rolling and compounding with 8mm thick 3004 aluminum plate, annealing heat treatment, cold-rolling, to obtain the copper-aluminum composite decorative material; the temperature of hot-rolling and compounding is 350 DEG C, The rolling speed of hot-rolling cladding is 6m / mi...

Embodiment 3

[0031] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0032] (1) The both sides surfaces of T2 copper plate of 1800mm wide 1.0mm thickness are electroplated tin, obtain the copper plate blank with two-layer tin-plated layer, the thickness of each layer of tin-plated layer is 0.020mm; Fraction 3% tin sulfamate, 3% sulfuric acid, 2% AlCl 3 and 4% trisodium phosphate, the solvent is water; the temperature of electroplating tin is 320°C, the voltage is 380V, the current is 700A, and the current density is 4.5A / dm 2 ;

[0033] (2) With the tin-plated layer of the copper plate blank with the tin-plated layer facing the aluminum plate, hot rolling and compounding with two 8mm thick 4343 aluminum plates, annealing heat treatment, cold rolling, obtain copper-aluminum composite decorative material; the temperature of hot-rolling compounding is 350 ℃, the rolling speed of hot rolling composite is 6m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com