Preparation method of magnetic response dynamic coating

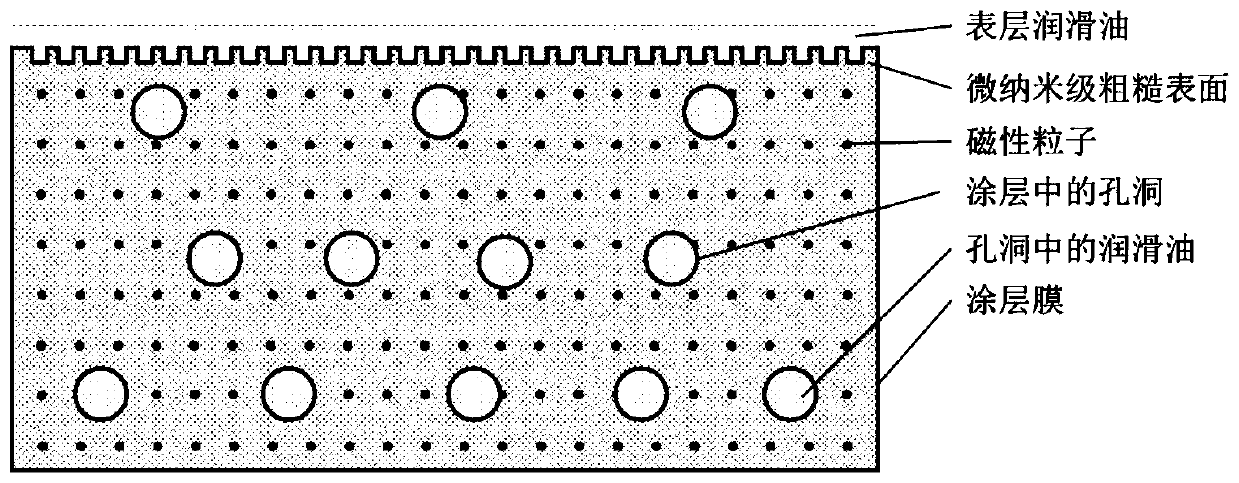

A dynamic coating, magnetic response technology, applied in coatings, magnetic coatings, devices for coating liquids on surfaces, etc., can solve the problem that the protection process is no longer controlled, and achieve long-term excellent self-cleaning and anti-fouling performance, the effect of preventing surface scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Magnetic particle modification

[0037] Mix 10 mL of ethanol with a volume fraction of 92% and 0.1 mL of silane coupling agent, stir for 30 minutes, and after the solution is uniformly mixed and hydrolyzed, select 1 g of carbonyl iron powder with a particle size of 1200 mesh and add it to the mixed solution. Introduce nitrogen gas to remove oxygen in the solution, and stir in nitrogen atmosphere to prevent oxidation of magnetic particles. After stirring for 6 hours at a rotational speed of 1200r / min, the carbonyl iron particles were adsorbed to the bottom of the beaker with a magnet, the supernatant was poured off, washed with ethanol three times, and the carbonyl iron particles were dried in a vacuum.

[0038] (2) Preparation of magnetically responsive porous substrates

[0039] Take 8g of PDMS, 6g of modified carbonyl iron and mix evenly, and stir at 600r / min for 2 hours; take 2g of ammonium carbonate, grind it, and use a 300-mesh fine sieve to screen 0.5g of sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com