Method for preparing bionic skeletal muscle composite tissue through multi-channel extrusion 3D biological printing

A bioprinting, composite tissue technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of providing bone lesions, inability to combine, muscles without function, etc., and achieves simple preparation method, small fibrosis, and comprehensive performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

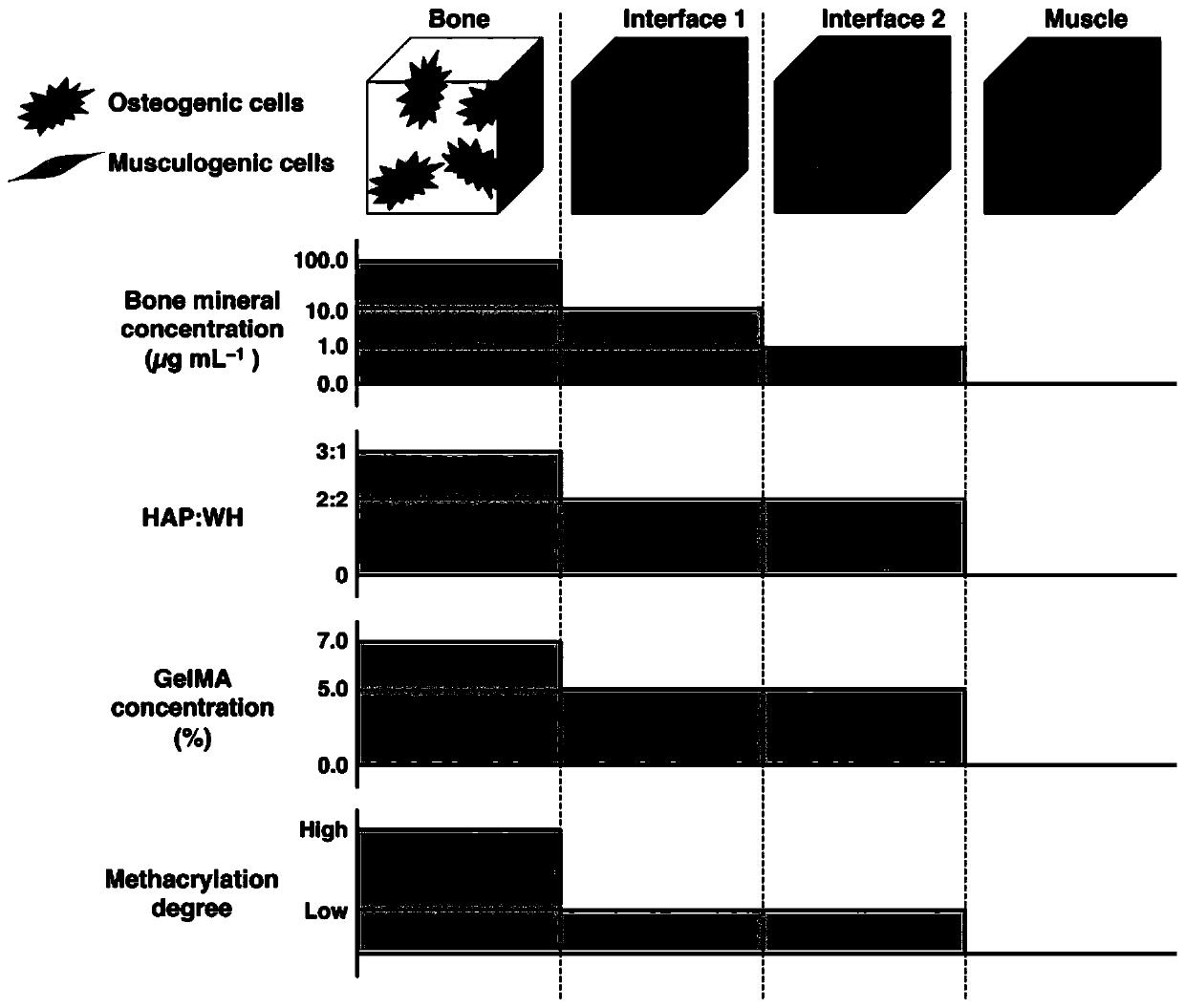

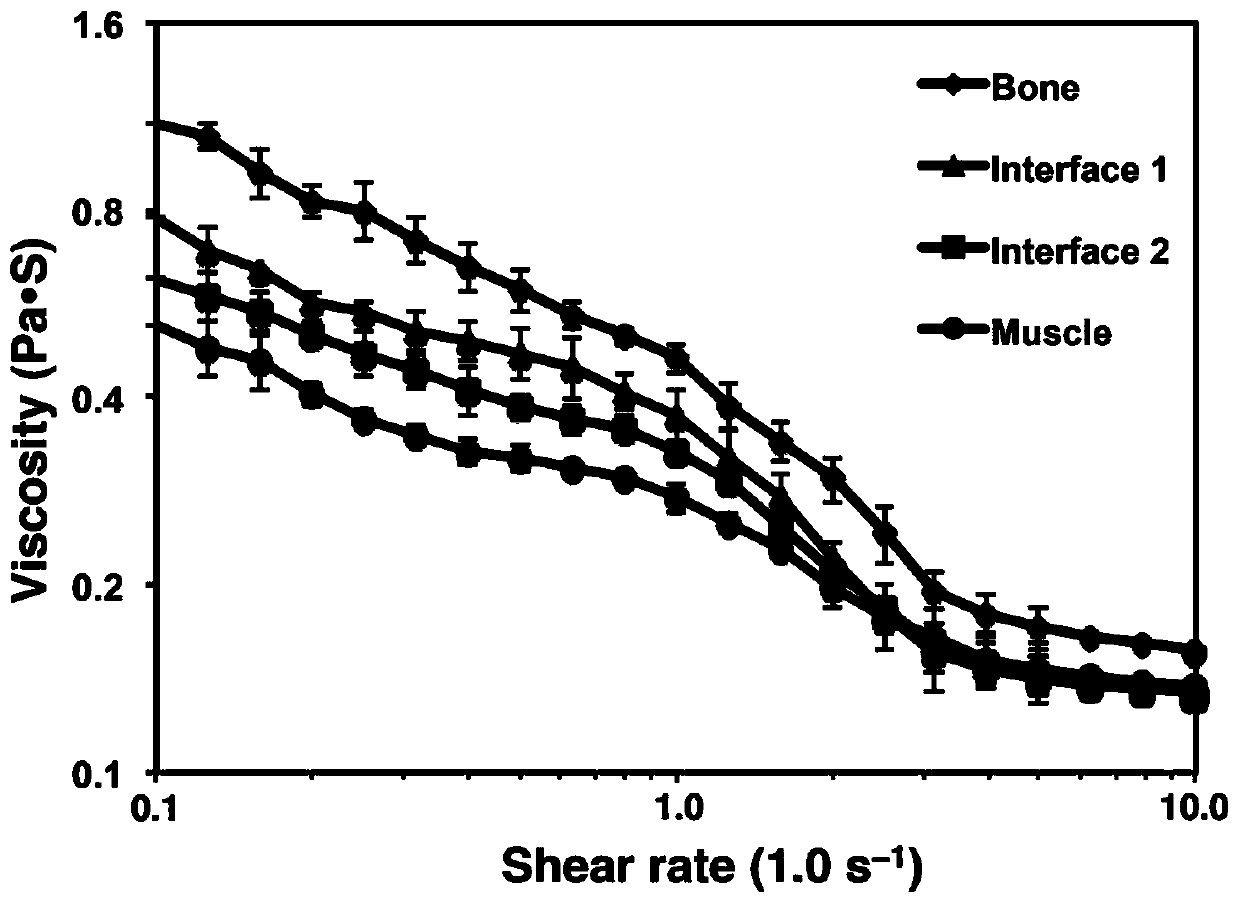

[0066] A bionic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting, prepared by the following preparation method:

[0067] S1. By dropping MA into the gelatin aqueous solution, the degree of substitution of MA in the bionic bone is 81.4%, that of the bionic periosteum is 19.7%, that of the bionic muscle fiber membrane is 19.7%, and that of the bionic muscle is 19.7%.

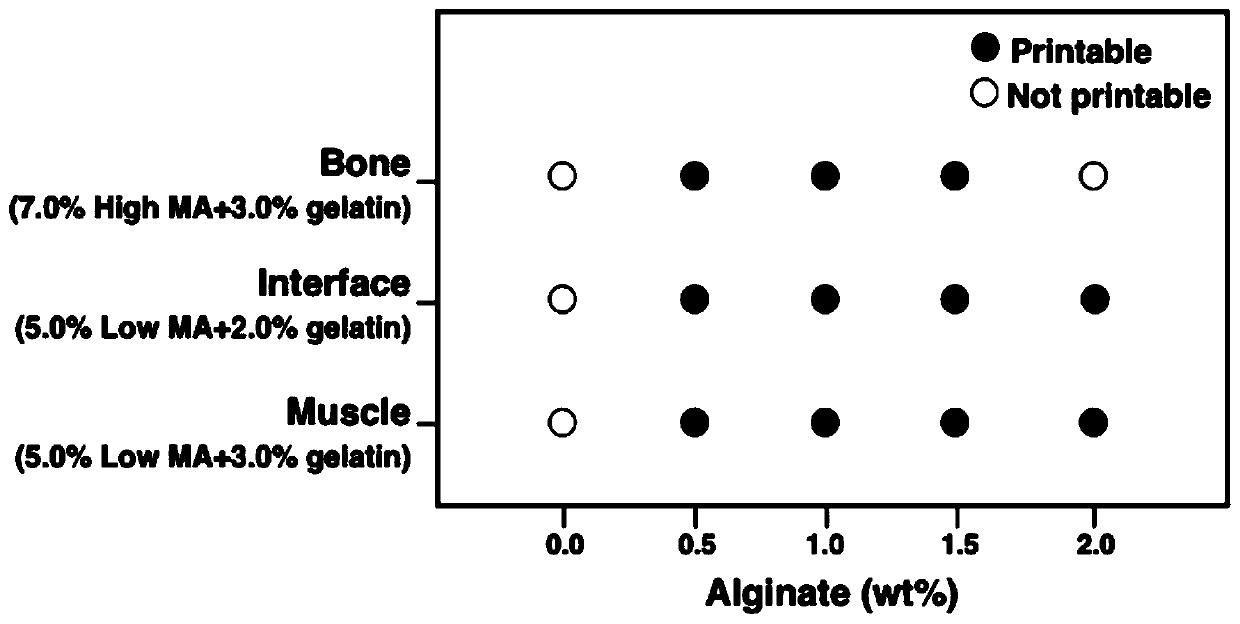

[0068] S2. The concentration of GelMA in the bionic bone is 7.0% (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 3.0% (W / V); the concentration of GelMA in the bionic periosteum scaffold is 5.0 % (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 2.0% (W / V); the concentration of GelMA in the biomimetic sarcolemma scaffold is 5.0% (W / V), the concentration of SA The concentration is 0.5% (W / V) and the concentration of gelatin is 2.0% (W / V); the concentration of GelMA in the bionic muscle scaffold is 5.0% (W / V), the conce...

Embodiment 2

[0075] A bionic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting, prepared by the following preparation method:

[0076] S1. By adding MA dropwise to the gelatin aqueous solution, the substitution degree of MA in the bionic bone is 90.0%, that of the bionic periosteum is 25.0%, that of the bionic muscle fiber membrane is 25.0%, and that of the bionic muscle is 25.0%.

[0077] S2. The concentration of GelMA in the bionic bone is 6.0% (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 3.0% (W / V); the concentration of GelMA in the bionic periosteum scaffold is 4.0 % (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 2.0% (W / V); the concentration of GelMA in the biomimetic sarcolemma scaffold is 4.0% (W / V), the concentration of SA The concentration is 0.5% (W / V) and the concentration of gelatin is 2.0% (W / V); the concentration of GelMA in the bionic muscle scaffold is 4.0% (W / V), the con...

Embodiment 3

[0084] A bionic skeletal muscle composite tissue prepared by multi-channel extrusion 3D bioprinting, prepared by the following preparation method:

[0085] S1. By dropping MA into the gelatin aqueous solution, the degree of substitution of MA in the bionic bone is 81.4%, that of the bionic periosteum is 19.7%, that of the bionic muscle fiber membrane is 19.7%, and that of the bionic muscle is 19.7%.

[0086] S2. The concentration of GelMA in the bionic bone is 7.0% (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 4.0% (W / V); the concentration of GelMA in the bionic periosteum scaffold is 5.0 % (W / V), the concentration of SA is 0.5% (W / V) and the concentration of gelatin is 3.0% (W / V); the concentration of GelMA in the biomimetic sarcolemma scaffold is 5.0% (W / V), the concentration of SA The concentration is 0.5% (W / V) and the concentration of gelatin is 3.0% (W / V); the concentration of GelMA in the bionic muscle scaffold is 5.0% (W / V), the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com