Bacterial cellulose/emu oil composite membrane and preparation method thereof

A technology of bacterial cellulose film and bacterial cellulose, which is applied in the field of bacterial cellulose/emu oil composite film and its preparation, can solve the problem that hydrophobic emu oil is difficult to compound completely, and achieve good biocompatibility, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

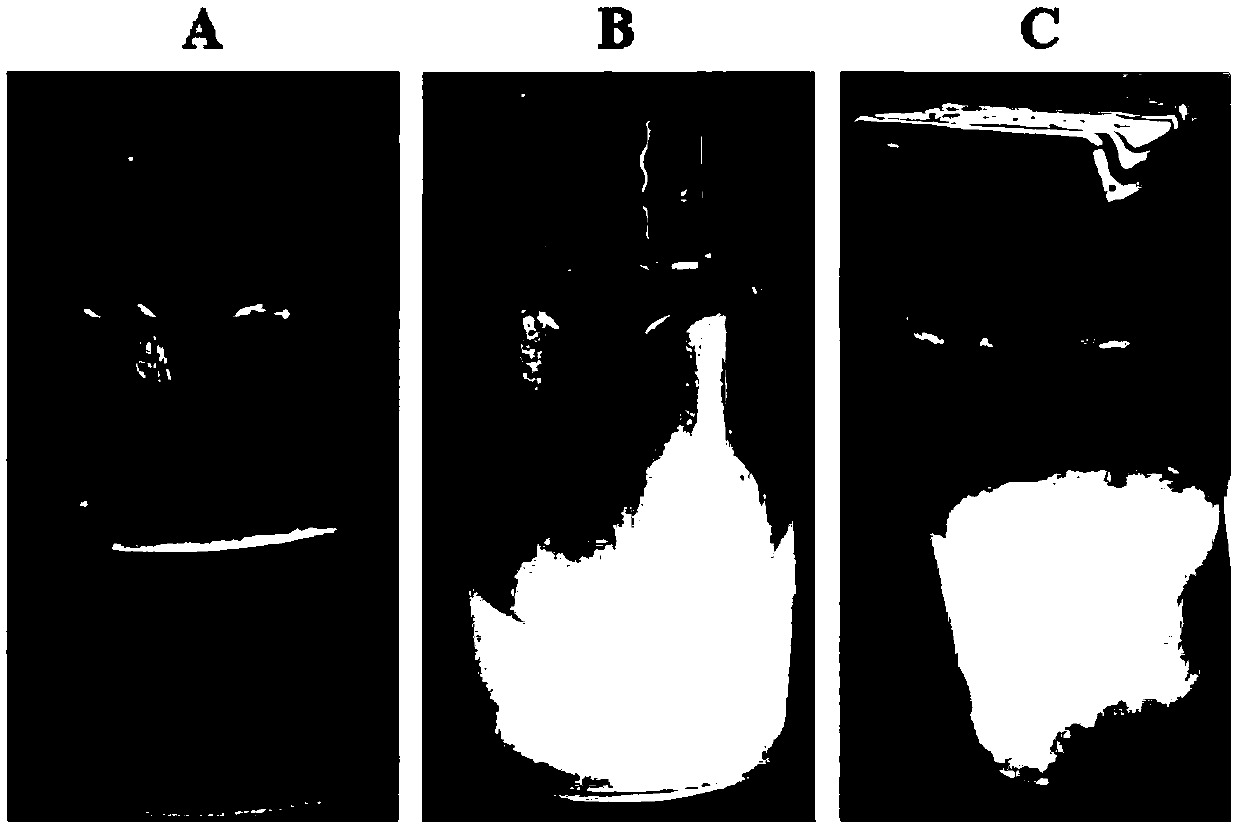

Image

Examples

Embodiment 1

[0029] After the emu oil is liquefied at 40-60°C, it is slowly dropped into the emulsifier cetyltrimethylammonium bromide solution, and the mass ratio of the emu oil to the emu oil is 0.1:5, 40-60 Stir and emulsify at ℃ to obtain a stable and uniform emu oil emulsion, then place the bacterial cellulose membrane in the emulsion to fully soak, stir and mix at 40-60℃, take out the mixed bacterial cellulose membrane, wash it with water, and remove the residual emulsion on the surface Freeze-dried for 12 hours to prepare bacterial cellulose / emu oil composite film.

Embodiment 2

[0031] After the emu oil is liquefied at 40-60°C, it is slowly dropped into the emulsifier cetyltrimethylammonium bromide solution, and the mass ratio of the emu oil to the emu oil is 0.9:5, 40-60 Stir and emulsify at ℃ to obtain a stable and uniform emu oil emulsion, then place the bacterial cellulose membrane in the emulsion to fully soak, stir and mix at 40-60℃, take out the mixed bacterial cellulose membrane, wash it with water, and remove the residual emulsion on the surface Freeze-dried to prepare bacterial cellulose / emu oil composite film.

Embodiment 3

[0033] After the emu oil is liquefied at 40-60°C, it is slowly dropped into the emulsifier cetyltrimethylammonium bromide solution, and the mass ratio of the emu oil to the emu oil is 2:5, 40-60 Stir and emulsify at ℃ to obtain a stable and uniform emu oil emulsion, then place the bacterial cellulose membrane in the emulsion to fully soak, stir and mix at 40-60℃, take out the mixed bacterial cellulose membrane, wash it with water, and remove the residual emulsion on the surface Freeze-dried to prepare bacterial cellulose / emu oil composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com