Biodegradable medical polymer tubing and preparation method thereof

A biodegradable polymer technology, applied in the field of biodegradable medical polymer tubing and its preparation, can solve the problems of difficult biodegradable polymer processing high-precision tubing, etc., to save production costs, simple operation, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

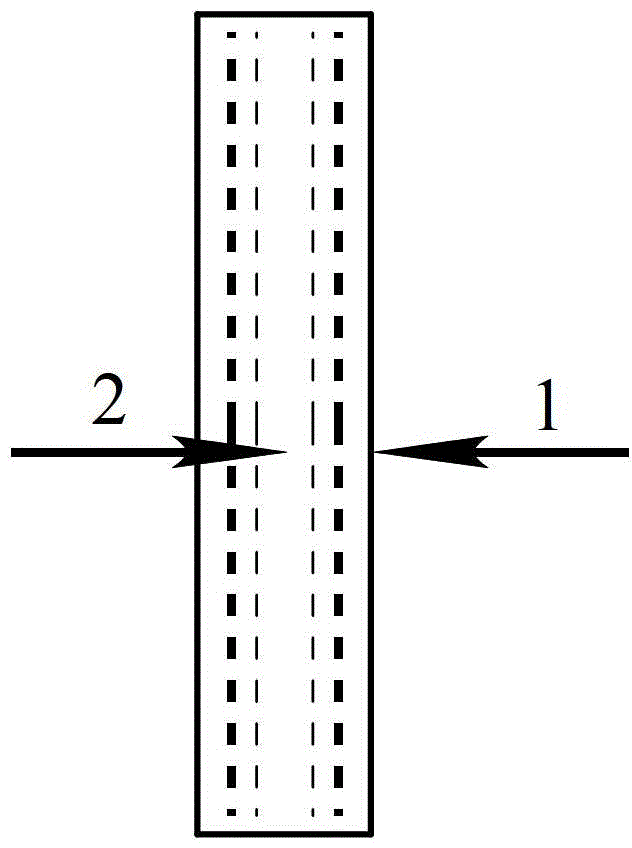

Image

Examples

Embodiment 1

[0040] Assemble the PTFE mold core with an outer diameter of 2mm and the PTFE shell with an inner diameter of 3mm concentrically and coaxially, place them in the reactor, add 0.1mol trimethylene carbonate at the same time, and vacuumize for 3 Add stannous octoate as a catalyst after the first time, the molar ratio of trimethylene carbonate to catalyst is 1000:1, vacuumize 3 times under reduced pressure (vacuum degree <15Pa), seal the tube under vacuum conditions, and perform bulk polymerization reaction at 130°C for 24h After taking it out, cooling and demolding can obtain a polytrimethylene carbonate pipe material with an inner diameter of 2 mm and a wall thickness of 0.5 mm.

Embodiment 2

[0042] After treating the stainless steel mold core with an outer diameter of 3mm and the stainless steel shell with an inner diameter of 5mm with a fluorine release agent, assemble them together concentrically and coaxially and place them in a reactor. After vacuuming for 3 times, stannous octoate was added as a catalyst, the molar ratio of caprolactone to catalyst was 3000:1, vacuum was pumped for 3 times under reduced pressure (vacuum degree <15Pa), and the tube was sealed under vacuum conditions. After bulk polymerization at 150° C. for 48 hours, take it out, cool and demould to obtain a polycaprolactone pipe with an inner diameter of 3 mm and a wall thickness of 1 mm.

Embodiment 3

[0044] After the glass mold core with an outer diameter of 5mm and the glass shell with an inner diameter of 10mm are silanized, they are assembled together concentrically and coaxially and placed in a reactor, and 0.3mol of trimethylene carbonate and 0.7mol of caprolactone are added at the same time And 0.001mol cross-linking agent 5,5'-(propane-diyl)dioxepan-2-one, add stannous octoate as a catalyst after decompression and vacuuming for 3 times, the addition amount is 0.0002mol, decompression Vacuum 3 times (vacuum degree <15Pa), seal the tube under vacuum condition. Take it out after bulk polymerization at 110°C for 36 hours, cool and demould to obtain a trimethylene carbonate-caprolactone cross-linked copolymer pipe with an inner diameter of 5 mm, a wall thickness of 2.5 mm, and a cross-linking density of 0.2%. According to the preparation method of Example 3, adjusting the copolymerization ratio of TMC and CL and the usage amount of the crosslinking agent BTB can obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com