Preparation method of novel phosphate composite ceramic solidified body material

A technology of composite ceramics and phosphate, which is applied in the solidification treatment of high-radioactive nuclear waste and the preparation of new phosphate composite ceramic solidified body, which can solve the problems of long and shortened preparation cycle, so as to save the energy consumption of the mill and shorten the production time. The effect of fine grinding time and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

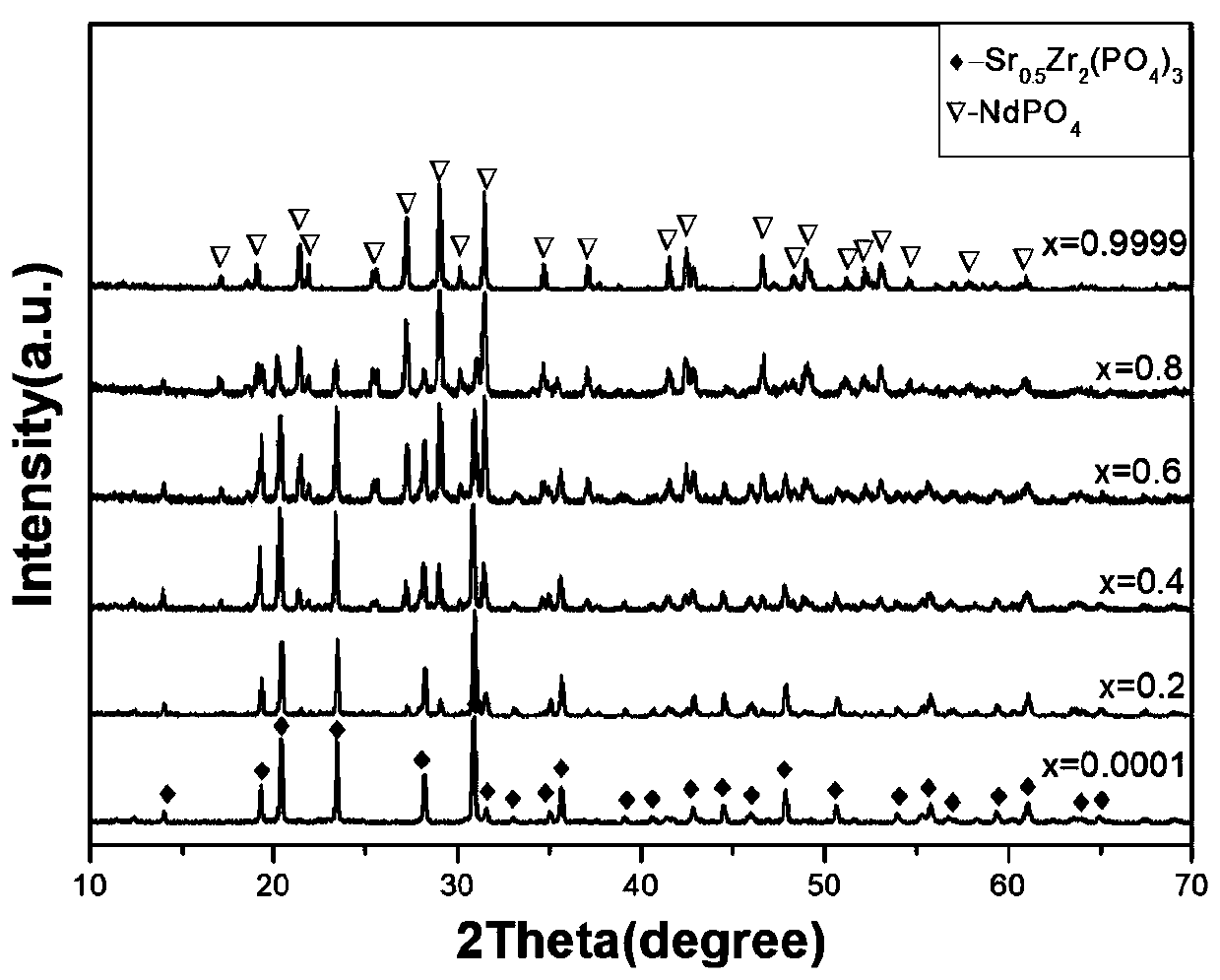

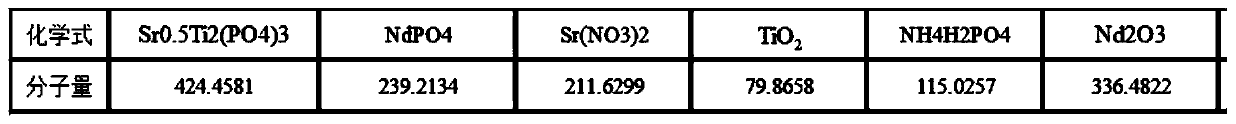

[0040] A 0.5 B 2 (PO 4 ) 3 -(Ln,An)PO 4 The general formula of the chemical composition of the type phosphate composite ceramic solidified body is (1-x)Sr 0.5 Ti 2 (PO 4 ) 3 -xNdPO 4 , wherein x is 0.0001; its preparation process comprises the following steps:

[0041] (1) Ingredients: TiO 2 , NH 4 h 2 PO 4 , Sr(NO 3 ) 2 、Nd 2 o 3 As the raw material, according to the stoichiometric ratio of the cured body, such as Figure 4 shown;

[0042] (2) Mixing and pre-sintering treatment: After mixing each raw material with a ball mill for 4 hours, pre-sinter at 600°C for 8 hours in a muffle furnace;

[0043] (3) Add 1wt% ZnO to the calcined powder as a sintering aid, and use a planetary ball mill to mill again for 24 hours for mechanical activation;

[0044] (4) Molding and molding: the obtained powder is granulated and shaped, and isostatically pressed under a pressure of 200MPa, and then the molded green body is kept at 700°C for 1 hour in a muffle furnace for moldi...

Embodiment 2

[0047] A 0.5 B 2 (PO 4 ) 3 -(Ln,An)PO 4 The general formula of the chemical composition of the type phosphate composite ceramic solidified body is (1-x)Sr 0.5 Ti 2 (PO 4 ) 3 -xNdPO 4 , wherein x is 0.2; its preparation process comprises the following steps:

[0048] (1) Ingredients: TiO 2 , NH 4 h 2 PO 4 , Sr(NO 3 ) 2 、Nd 2 o 3 As the raw material, according to the stoichiometric ratio of the cured body, such as Figure 5 shown;

[0049] (2) Mixing and pre-sintering treatment: After mixing each raw material with a ball mill for 4 hours, pre-sinter at 600°C for 8 hours in a muffle furnace;

[0050] (3) Add 1wt% ZnO to the calcined powder as a sintering aid, and use a planetary ball mill to mill again for 24 hours for mechanical activation;

[0051] (4) Molding and molding: the obtained powder is granulated and shaped, and isostatically pressed under a pressure of 200MPa, and then the molded green body is kept at 700°C for 1 hour in a muffle furnace for moldin...

Embodiment 3

[0054] The chemical composition of a NZP type-monazite type phosphate composite ceramic solidified body is (1-x)Sr 0.5 Ti 2 (PO 4 ) 3 -xNdPO 4 , x is 0.4; Its preparation process comprises the following steps:

[0055] (1) Ingredients: TiO 2 , NH 4 h 2 PO 4 , Sr(NO 3 ) 2 、Nd 2 o 3 As the raw material, according to the stoichiometric ratio of the cured body, such as Figure 6 shown;

[0056] (2) Mixing and pre-sintering treatment: After mixing each raw material with a ball mill for 4 hours, pre-sinter at 600°C for 8 hours in a muffle furnace;

[0057] (3) Add 1wt% ZnO to the calcined powder as a sintering aid, and use a planetary ball mill to mill again for 24 hours for mechanical activation;

[0058] (4) Molding and molding: the obtained powder is granulated and shaped, and isostatically pressed under a pressure of 200MPa, and then the molded green body is kept at 700°C for 1 hour in a muffle furnace for molding;

[0059] (5) Sintering: The green body is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com