Multi-core-shell structure nickel-based catalyst applied to carbon dioxide reforming reaction, and preparation method and use of multi-core-shell structure nickel-based catalyst

A nickel-based catalyst and carbon dioxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as environmental pollution, waste of resources, and low utilization rate , to reduce costs, save resources, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

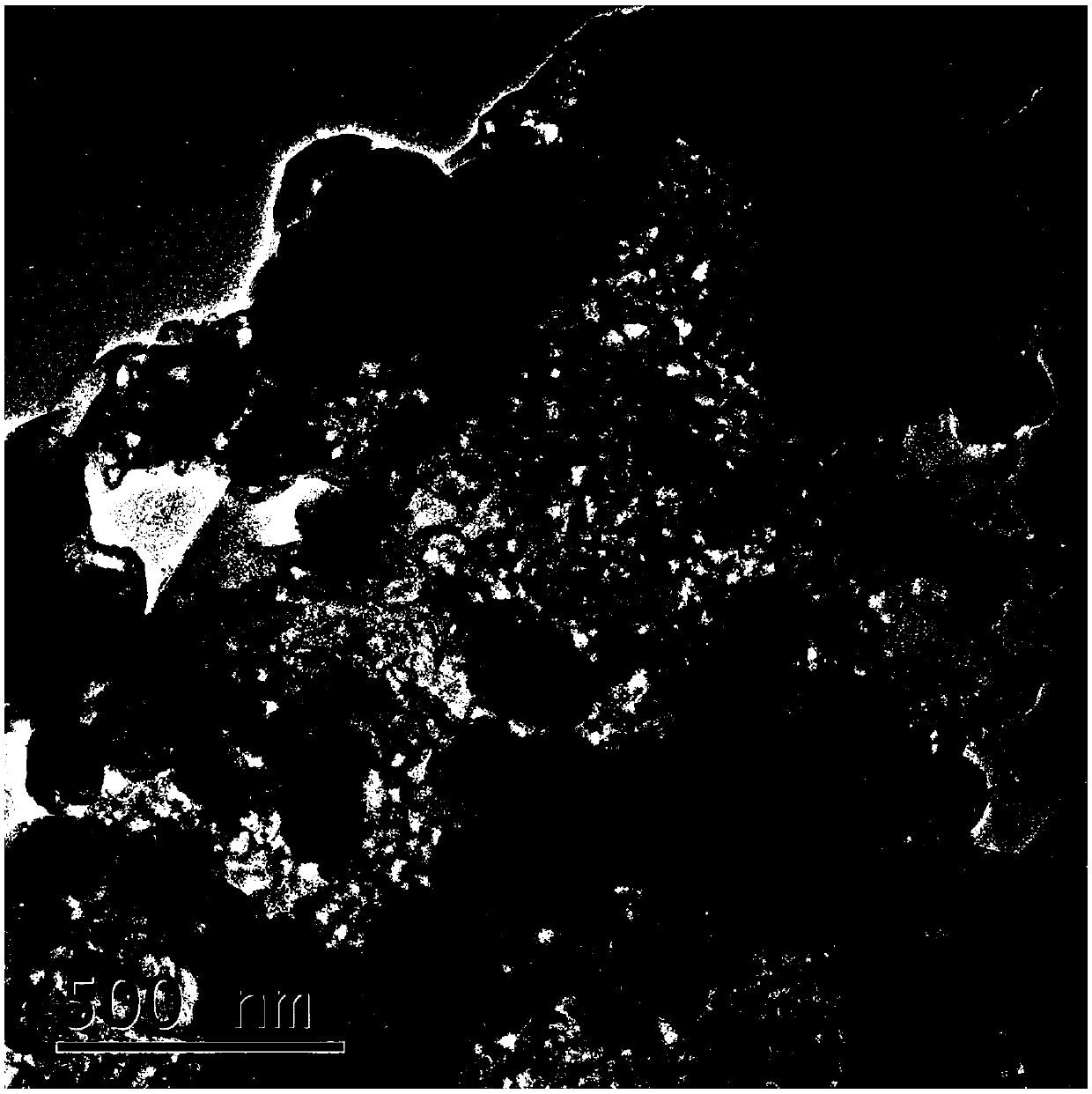

Image

Examples

Embodiment 1

[0064] Preparation of catalyst:

[0065] (1) Take 13.612 g of nickel sulfate hexahydrate and dissolve it in 100 mL of deionized water to prepare 0.52 mol / L solution A.

[0066] (2) Take 6.162 g of magnesium sulfate heptahydrate, dissolve it in 100 mL of deionized water to prepare a 0.25 mol / L solution, mix it with solution A and make solution B.

[0067] (3) Dehydrate and crush the bagasse to 10-20 mesh, take 150g into a flat-bottomed flask containing 1000mL 0.2mol / L hydrochloric acid solution, reflux for 12 hours at a temperature of 90℃ and a rotation speed of 700RPM, and then deionize The supernatant was washed with water until the pH of the supernatant was 7, and then it was placed in a drying cabinet and dried at 110°C for 15 hours to obtain solid C. The solid C was further treated with hydrothermal carbonization reaction maintained at 180°C for 18 hours, washed with deionized water, and dried at 110°C for 15 hours to obtain 20 g of a porous core-shell carbon material.

[0068] (...

Embodiment 2

[0076] Preparation of catalyst:

[0077] (1) Dissolve 13.612 g of nickel sulfate hexahydrate in 100 mL of deionized water to prepare solution A with a concentration of 0.52 mol / L.

[0078] (2) Take 12.324g of magnesium sulfate heptahydrate and dissolve it in 100 mL of deionized water to prepare a 0.50mol / L solution, mix it with solution A and make solution B.

[0079] (3) After the bagasse is dehydrated and crushed to 10-20 mesh, take 200g into a flat-bottomed flask containing 1000mL 0.2mol / L phosphoric acid solution, reflux for 10 hours at a temperature of 90°C and a rotation speed of 700RPM, and then deionize The supernatant was washed with water to pH=7, and then dried at 110°C for 15 hours to obtain solid B. After the solid B was subjected to hydrothermal treatment maintained at 200°C for 20 hours, it was washed with deionized water, and dried at 110°C for 15 hours to obtain 18.75 g of porous core-shell carbon material.

[0080] (4) Add the porous core-shell structured carbon mat...

Embodiment 3

[0087] Preparation of catalyst:

[0088] (1) Dissolve 13.612 g of nickel nitrate hexahydrate in 100 mL of deionized water, stir until completely dissolved, and prepare solution A with a concentration of 0.52 mol / L.

[0089] (2) Take 19.2 g of magnesium nitrate hexahydrate, dissolve it in 100 mL of deionized water to prepare a 0.75 mol / L solution, mix it with solution A and make solution B.

[0090] (3) Add 15 g of activated carbon to solution B, immerse it at room temperature for 24 hours, and then dry it at 110°C for 15 hours to obtain 30 g of solids.

[0091] (4) Take the solid solid obtained in step (3) and send it into a quartz reaction tube with an outer diameter of 10 mm, and use a program-controlled temperature heating tube furnace. The heating rate is controlled at 20 °C / min, and heated to a temperature of 150 mL / min in a nitrogen gas stream. After keeping the temperature at 900°C for 1.5 hours, wait until the temperature drops to room temperature to obtain 20 g of the require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com