Permanent antistatic polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene modification, can solve the problems of high cost, poor material mechanical properties, antistatic performance environment dependence and timeliness, etc., to reduce the amount of addition, improve tensile strength and bending modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

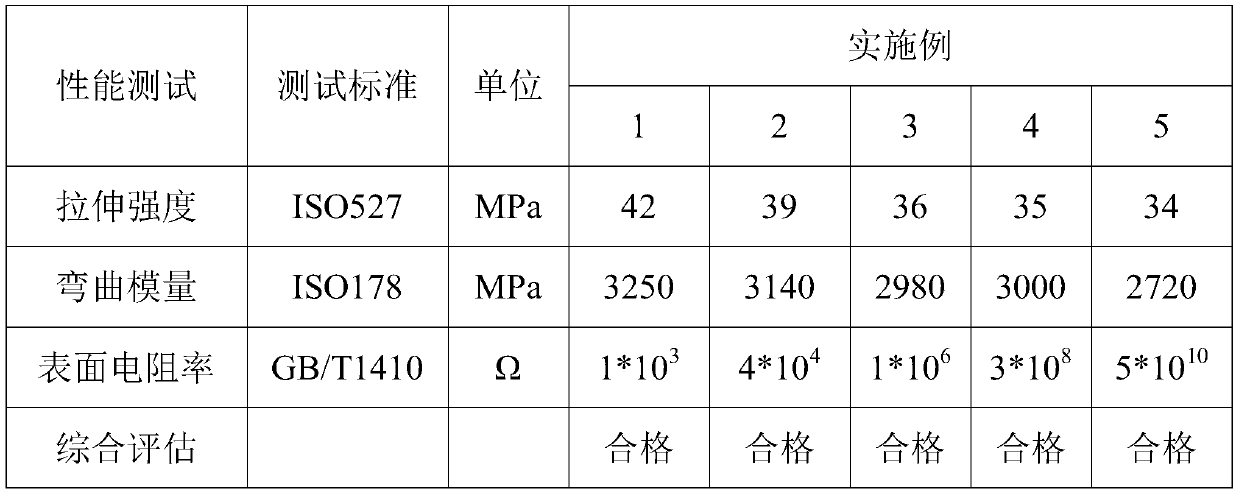

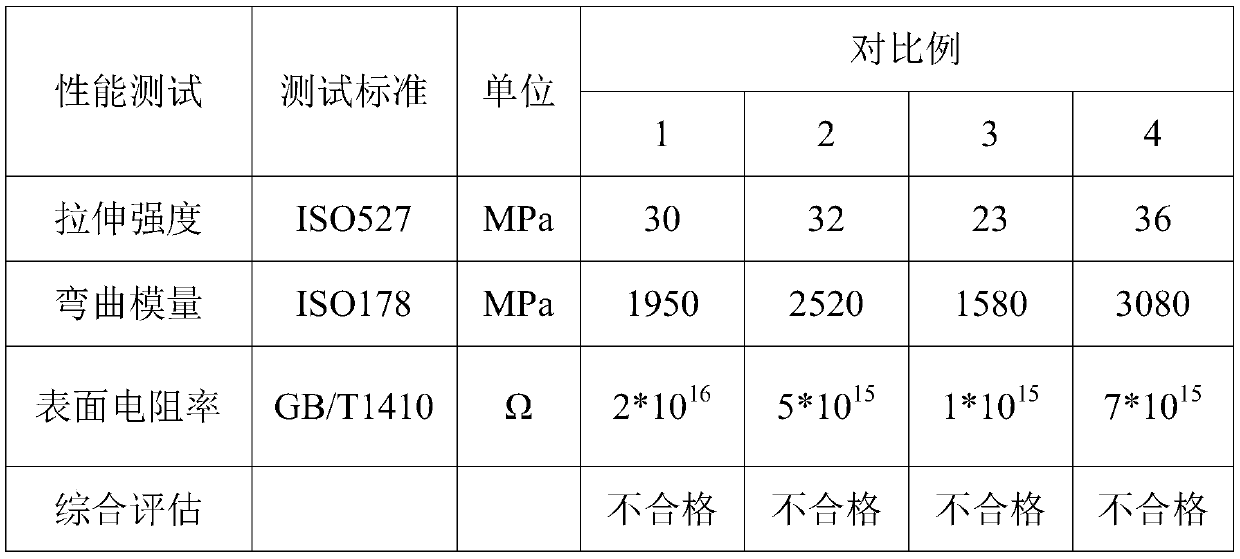

Examples

Embodiment 1

[0045] (1) Mix 150g of wollastonite W625 and 450mL of deionized water, add 3.0g of polyethylene glycol, stir well in a constant temperature water bath at 90°C, and set aside; slowly drop 20% of wollastonite into the suspension Hydrochloric acid solution, control the pH value to 2, let stand, react for 5 hours, wash with water three times, and dry at 120°C to obtain acid-treated wollastonite. Dissolve 5.0g of epoxy resin in 200mL of acetone, pour it into a beaker filled with 150g of acid-treated wollastonite, cover it with wollastonite powder, let it stand, and react for 4 hours, then dry it at 120°C and dry it at 700°C In a tube furnace, carbonize for 5 hours under a nitrogen atmosphere to obtain a carbon / wollastonite composite material.

[0046] (2) Take 100 g of superconducting carbon black AX-015 and 500 mL of nitric acid with a mass fraction of 0.35 in a beaker, stir at room temperature, and after reacting for 5 hours, wash the carbon black with deionized water until the p...

Embodiment 2

[0051] (1) Mix 120g of wollastonite W625 with 400mL of deionized water, add 2.0g of polyethylene glycol, stir well in a constant temperature water bath at 100°C, and set aside; slowly drop 20% of wollastonite into the suspension Hydrochloric acid solution, control the pH value to 3, let stand, react for 4 hours, wash with water three times, and dry at 100°C to obtain acid-treated wollastonite. Dissolve 4.0g of epoxy resin in 160mL of acetone, pour it into a beaker filled with 120g of wollastonite that has been treated with acid, cover it with wollastonite powder, let it stand for 3 hours, and then dry it at 120°C. In a type furnace, carbonize for 4 hours under a nitrogen atmosphere to obtain a carbon / wollastonite composite material.

[0052] (2) Take 80 g of superconducting carbon black AX-015 and 480 mL of nitric acid with a mass fraction of 0.35 in a beaker, stir at room temperature, and after reacting for 4 hours, wash the carbon black with deionized water until the pH valu...

Embodiment 3

[0057] (1) Mix 100g of wollastonite W625 and 350mL of deionized water, add 1.5g of polyethylene glycol, stir well in a constant temperature water bath at 80°C, and set aside; slowly drop 20% of wollastonite into the suspension Hydrochloric acid solution, control the pH value to 2, let stand, react for 3 hours, wash with water 3 times, and dry at 120°C to obtain acid-treated wollastonite. Dissolve 2.5g of epoxy resin in 120mL of acetone, pour it into a beaker filled with 100g of acid-treated wollastonite, cover it with wollastonite powder, let it stand, react for 2 hours and then dry it at 120°C. In a type furnace, carbonize for 3 hours under a nitrogen atmosphere to obtain a carbon / wollastonite composite material.

[0058] (2) Take 70g of superconducting carbon black AX-015 and 450mL of nitric acid with a mass fraction of 0.35 in a beaker, stir at room temperature, and after reacting for 3 hours, wash the carbon black with deionized water until the pH value of the washing solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com