Method for repairing heavy metal polluted soil

A technology of polluted soil and remediation method, applied in the restoration of polluted soil, etc., can solve problems such as adverse effects on soil fertility and unsatisfactory passivation effect, and achieve the goal of taking into account restoration efficiency, improving passivation rate, and taking into account passivation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

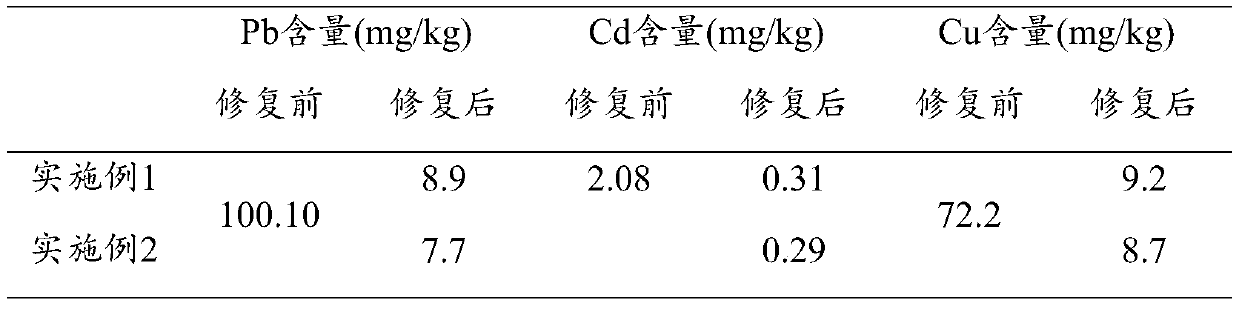

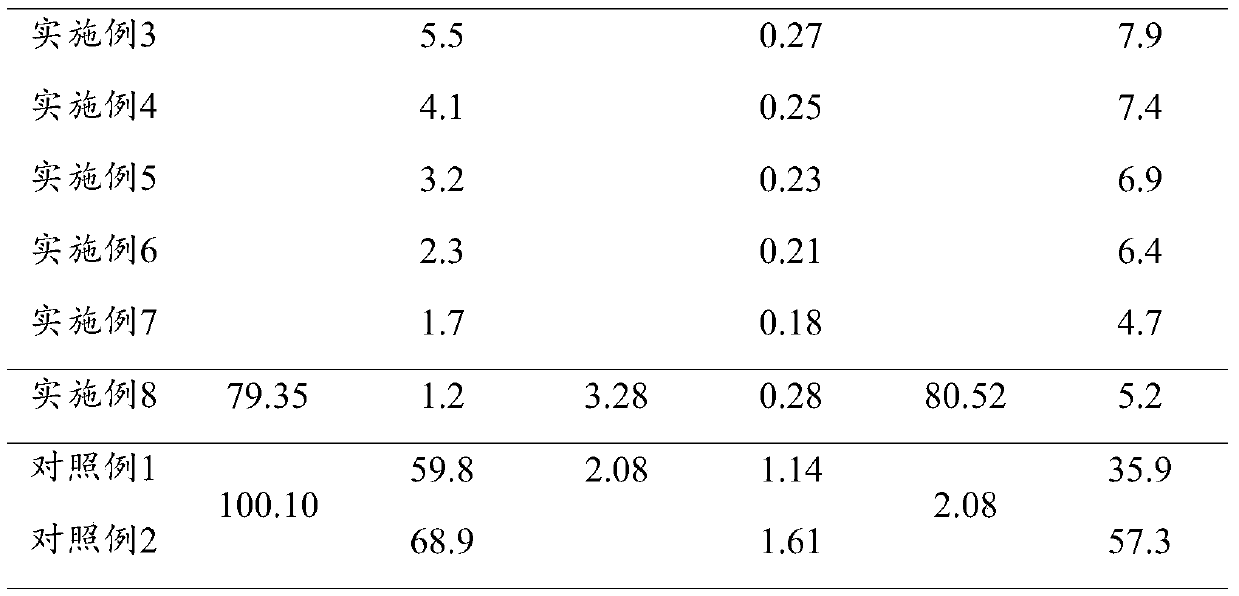

[0042] The soil in a titanium mining area was selected for restoration. The pollution of the soil is shown in Table 1.

[0043] Preparation of biochar:

[0044] Dry the rice straw, grind it into powder, put it into a horse boiling furnace, and heat it to 700°C for 2 hours to decompose.

[0045] Repair method:

[0046] first step,

[0047] Mix 1.5g / m of biochar into the soil 3 , while adding water until the water content reaches 45%, stir well, and cultivate for 40 days.

[0048] second step,

[0049] Then add bacteria solution 20L / m 3 Soil and calcium phosphate 5g / m 3 Soil, the concentration of bacteria solution is 2×10 8 CFU Escherichia coli / mL, continue to culture for 60 days, and turn over every other day during this period.

Embodiment 2

[0051] Contaminated soil and biochar sources are the same as in Example 1, and the remediation method is:

[0052] first step,

[0053] Mix 2.0g / m of biochar into the soil 3 , while adding water until the water content reaches 50%, stir well, and cultivate for 35 days.

[0054] second step,

[0055] Then add bacteria solution 35L / m 3 Soil and calcium phosphate 6.5g / m 3 Soil, the concentration of bacteria solution is 2.5×10 8 CFU Escherichia coli / mL, continue to culture for 75 days, and turn over every other day during this period.

Embodiment 3

[0057] Soil source is with embodiment 1.

[0058] Preparation of biochar:

[0059] Dry the rice straw, grind it into powder, put it into a horse boiling furnace, and heat it to 450°C for 2 hours to decompose.

[0060] The fix is:

[0061] first step,

[0062] Mix 2.0g / m of biochar into the soil 3 , while adding water until the water content reaches 50%, stir well, and cultivate for 35 days.

[0063] second step,

[0064] Then add bacteria solution 35L / m 3 Soil and calcium phosphate 6.5g / m 3 Soil, the concentration of bacteria solution is 2.5×10 8 CFU Escherichia coli / mL, continue to culture for 75 days, and turn over every other day during this period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com