A gradient transition type anti-icing full heat recovery core and its working method

A technology of total heat recovery and heat recovery core, which is applied in the field of total heat recovery core and gradual transitional anti-icing total heat recovery core, which can solve the problems that the core area cannot be effectively used for heat exchange and moisture transfer, etc. To achieve the effect of flexible and convenient use, change of area, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

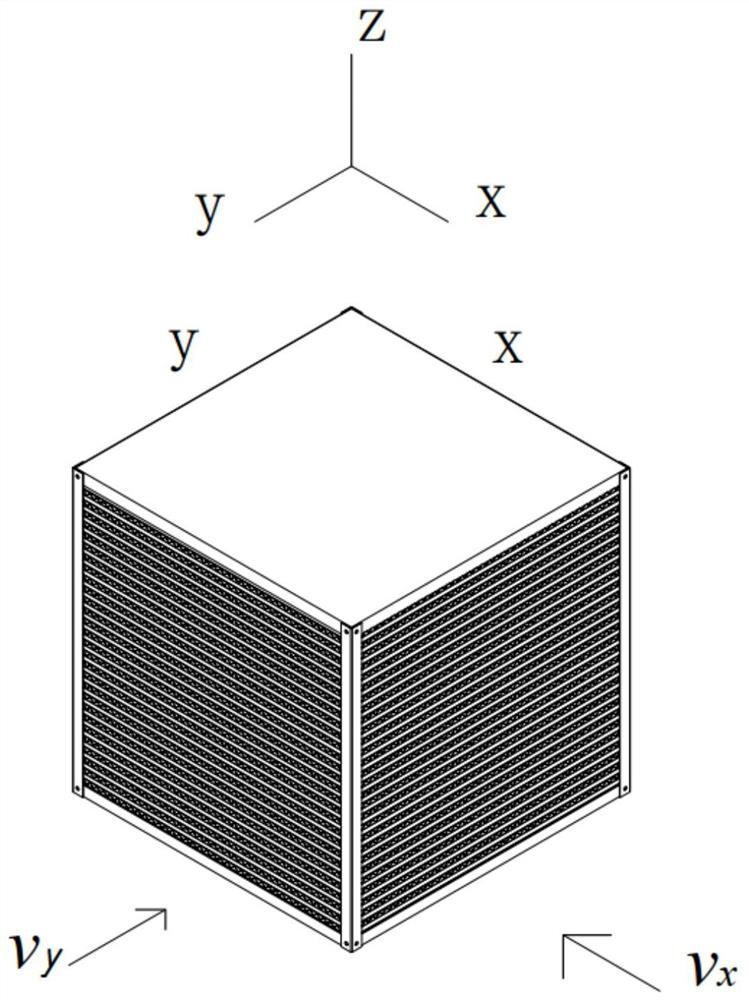

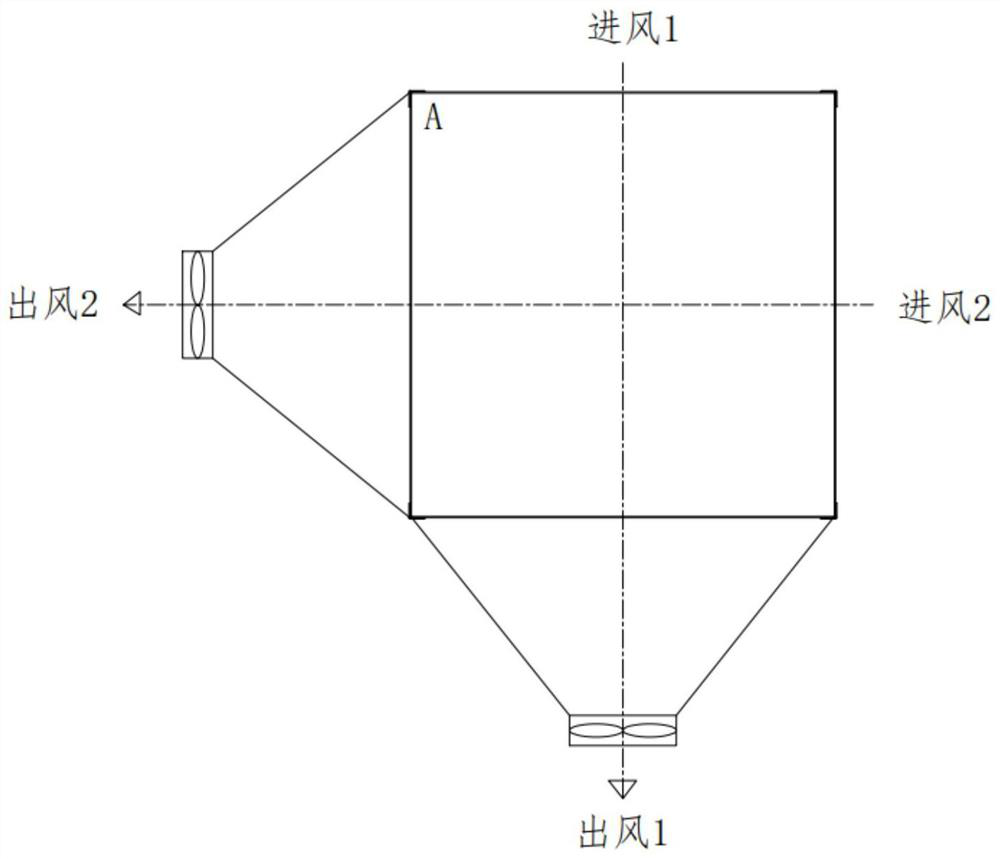

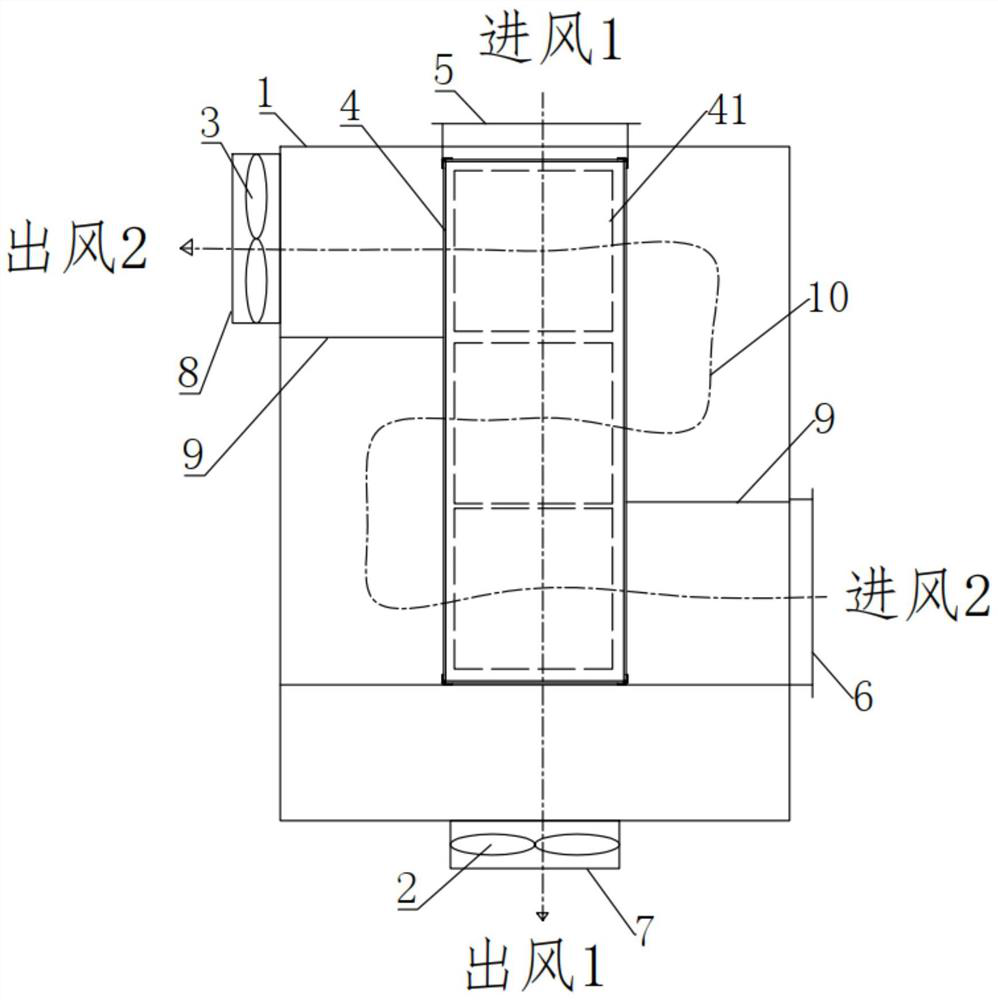

[0041] Such as image 3 The gradual and transitional anti-icing total heat recovery core body shown includes an outer casing 1, fan 1 2, fan 2 3, heat recovery unit 4, air inlet 1 5, air inlet 2 6, air outlet 1 7 and outlet Air outlet two 8, the heat recovery unit 4 is arranged in the outer casing 1, and the heat recovery unit 4 is located in the middle of the outer casing 1, the air inlet one 5, the air inlet two 6, the air outlet one 7 and the air outlet two 8 are all arranged on the outer wall of the outer casing 1, the air inlet-5 and the air outlet-7 are arranged facing each other, the two ends of the heat recovery unit 4 communicate with the air inlet-5 and the air outlet-7 respectively, the The air inlet one 5 and the air outlet two 8 are located on the same side of the outer casing 1, the air inlet two 6 and the air outlet one 7 are located on the other side of the outer casing 1 away from the air inlet one 5, and the fan one 2 is arranged at the air outlet One 7, the...

Embodiment 2

[0053] Such as Figure 5 The outer walls of the cold fin frame 415 and the hot fin frame 417 are provided with extension plates 20, and the ends of both sides of the extension plate 20 are provided with fin distance adjustment assemblies 30, and the cold fin frame 415 The fin distance adjustment assembly 30 on the frame 417 is connected to a set of cold fins 414 , and the fin distance adjustment assembly 30 on the heat fin frame 417 is connected to a set of heat fins 416 .

[0054] Such as Figure 6-8 The fin distance adjustment assembly 30 shown includes a telescopic cylinder 301, a fixed base 302, a linear optical axis 1 303, a linear optical axis 2 304, a set of upper spacing adjustment blocks 305 and a set of lower spacing adjustment blocks 306. The seat 302 is fixedly arranged on the upper end surface of the extension plate 20, the telescopic cylinder 301 is fixedly arranged on the fixed base 302, and the piston rod of the telescopic cylinder 301 passes through the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com