Composite process method for strengthening Ti-10V-2Fe-3Al alloy surface layer

A ti-10v-2fe-3al and composite process technology, which is applied in the composite process field of Ti-10V-2Fe-3Al alloy surface layer strengthening, can solve the problems such as the depth of the active layer and the reduction in hardness, and improve the surface structure and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

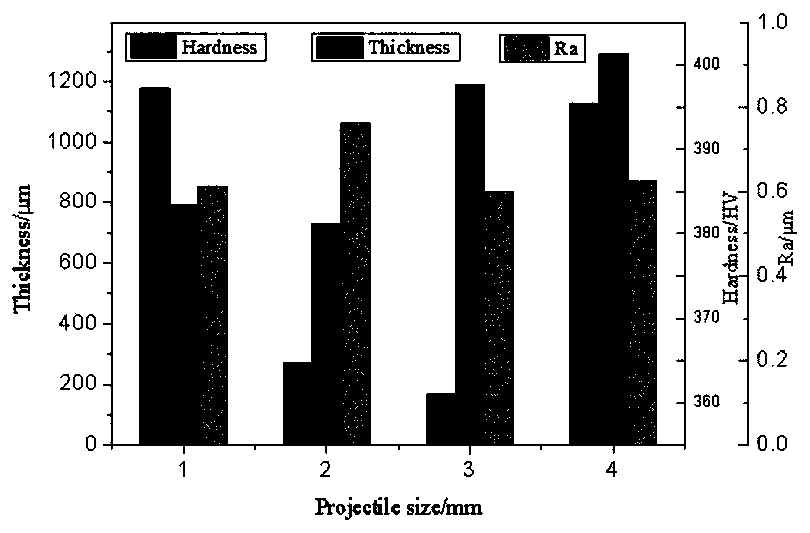

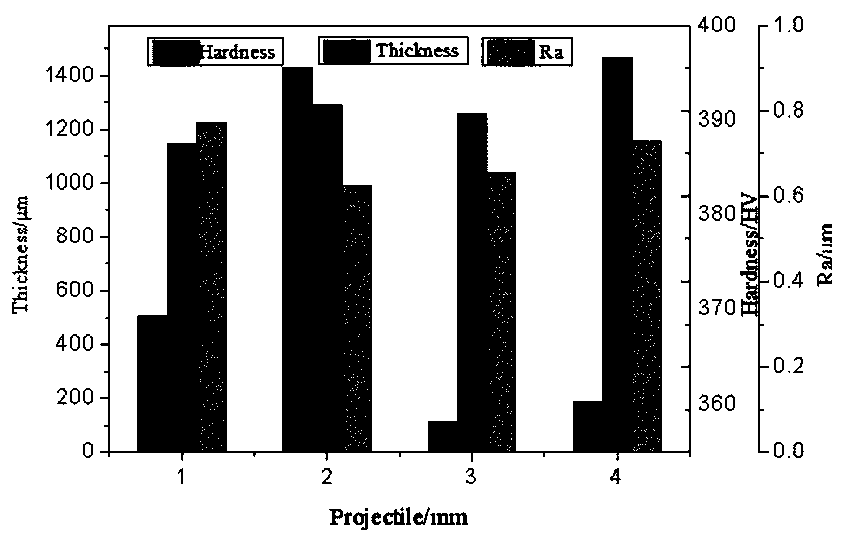

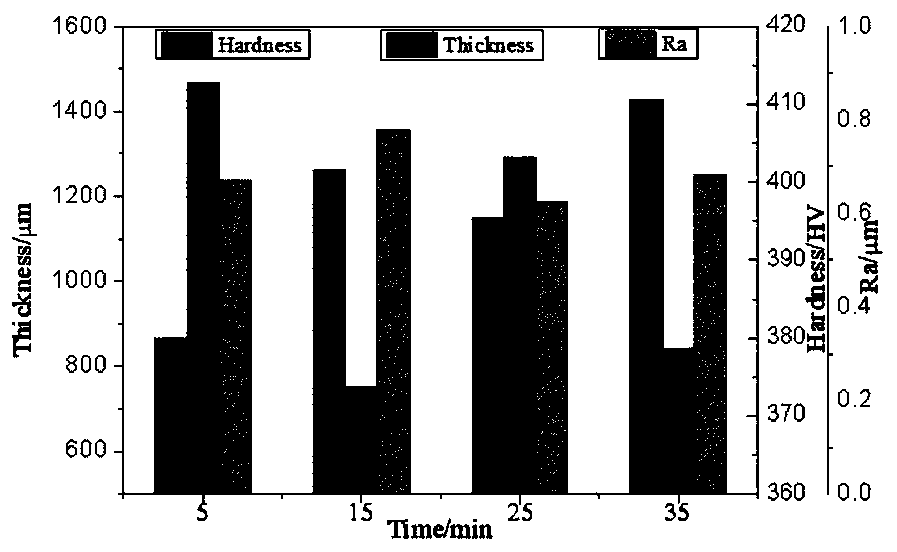

[0024] Step 1. Adopt the method of orthogonal experimental design

[0025] The four factors of dry shot peening size (mm), dry shot peening time (mim), wet shot peening size (mm) and wet shot peening time (min) were selected for orthogonal experiment, and four levels were selected for each factor, which is An experiment with 4 factors and 4 levels, the orthogonal table L16(4 5 ) to arrange the test. The designed orthogonal experiment design scheme and experimental results are shown in Table 1:

[0026] Table 1. Orthogonal experimental design table and results

[0027]

[0028] Step 2. Test result analysis

[0029] According to the range value in range analysis R=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com