High-performance zirconium-titanium binary alloy and preparation method thereof

A binary alloy and titanium alloy technology, applied in the field of new zirconium-titanium alloy and its preparation, can solve the problems of wear resistance, unsatisfactory dimensional stability, low strength, low hardness, etc., and achieve excellent radiation resistance, low The effect of density and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

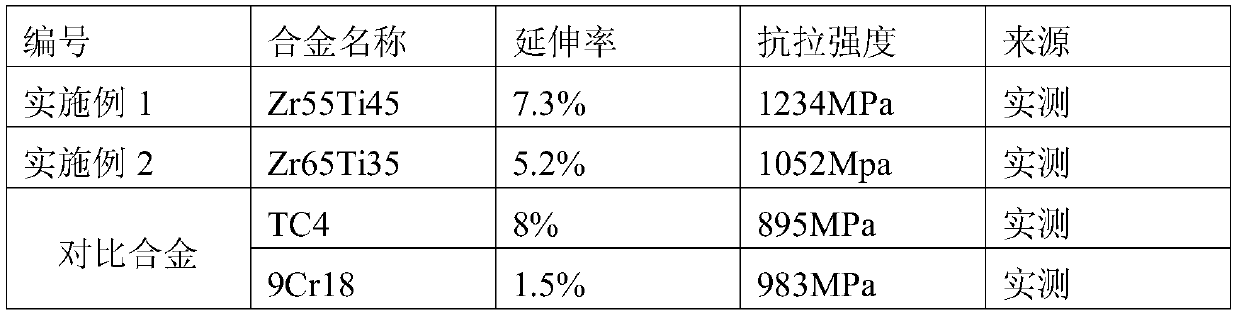

Examples

Embodiment 1

[0018] Industrial-grade zirconium sponge and titanium sponge are used for batching according to the atomic ratio of 55:45. After the surface is treated to remove scale, it is cleaned with ultrasonic waves and dried with a hair dryer. Mix the raw materials evenly and place them in a non-consumable electric arc furnace protected by an argon atmosphere, and turn over and smelt them 5 times for 6 minutes each time to ensure sufficient smelting to obtain an alloy ingot with a uniform composition. The smelted alloy ingot is put into a tube furnace, filled with argon gas for protection, kept at 900°C for 4 hours, and cooled with the furnace to make the composition of the alloy ingot more uniform. Put the zirconium-titanium alloy ingot that has been homogenized and annealed into a box-type resistance furnace, heat it to 700°C, keep it at this temperature for 40 minutes, and then quickly transfer the alloy ingot to a twin-roll mill for multi-pass rolling deformation . After the first ...

Embodiment 2

[0020] Industrial-grade zirconium sponge and titanium sponge are used for ingredients according to the atomic ratio of 65:35. After the surface is treated to remove scale, it is cleaned with ultrasonic waves and dried with a hair dryer. Mix the raw materials evenly and put them into a non-consumable electric arc furnace protected by an argon atmosphere, and turn over and smelt them 5 times, each time for 8 minutes, to ensure sufficient smelting to obtain alloy ingots with uniform composition. The smelted alloy ingot is put into a tube furnace, filled with argon for protection, kept at 1100°C for 4 hours, and cooled with the furnace to make the composition of the alloy ingot more uniform. Put the zirconium-titanium alloy ingot that has been homogenized and annealed into a box-type resistance furnace, heat it to 900°C, keep it at this temperature for 40 minutes, and then quickly transfer the alloy ingot to a twin-roll mill for multi-pass rolling deformation . After the first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com