High-performance lithium battery and preparation method thereof

A lithium battery, high-performance technology, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of inconsistent electrical properties of the inner and outer layers of the battery, high risk of manual operation, and high requirements for electrolytes. Improve the appearance and size consistency and stability, good performance consistency and stability, and improve the effect of performance consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In the preparation method of the existing lithium battery, the formation step generally reduces the interface impedance between the positive and negative electrodes and the diaphragm through external conditions such as high temperature and high pressure, improves the permeability of lithium ions, accelerates the formation of the SEI film and increases its density, resulting in the existing The preparation method of lithium battery has the problems of high energy consumption, complex and expensive equipment, special and expensive electrolyte, and poor battery stability.

[0036] For this reason, the present invention provides a kind of preparation method of high-performance lithium battery, and this lithium battery can be the liquid lithium ion battery such as winding type lithium ion battery, laminated lithium ion battery, square lithium ion battery, soft pack lithium ion battery, etc. batteries, polymer lithium batteries, semi-solid lithium-ion batteries and all-solid-s...

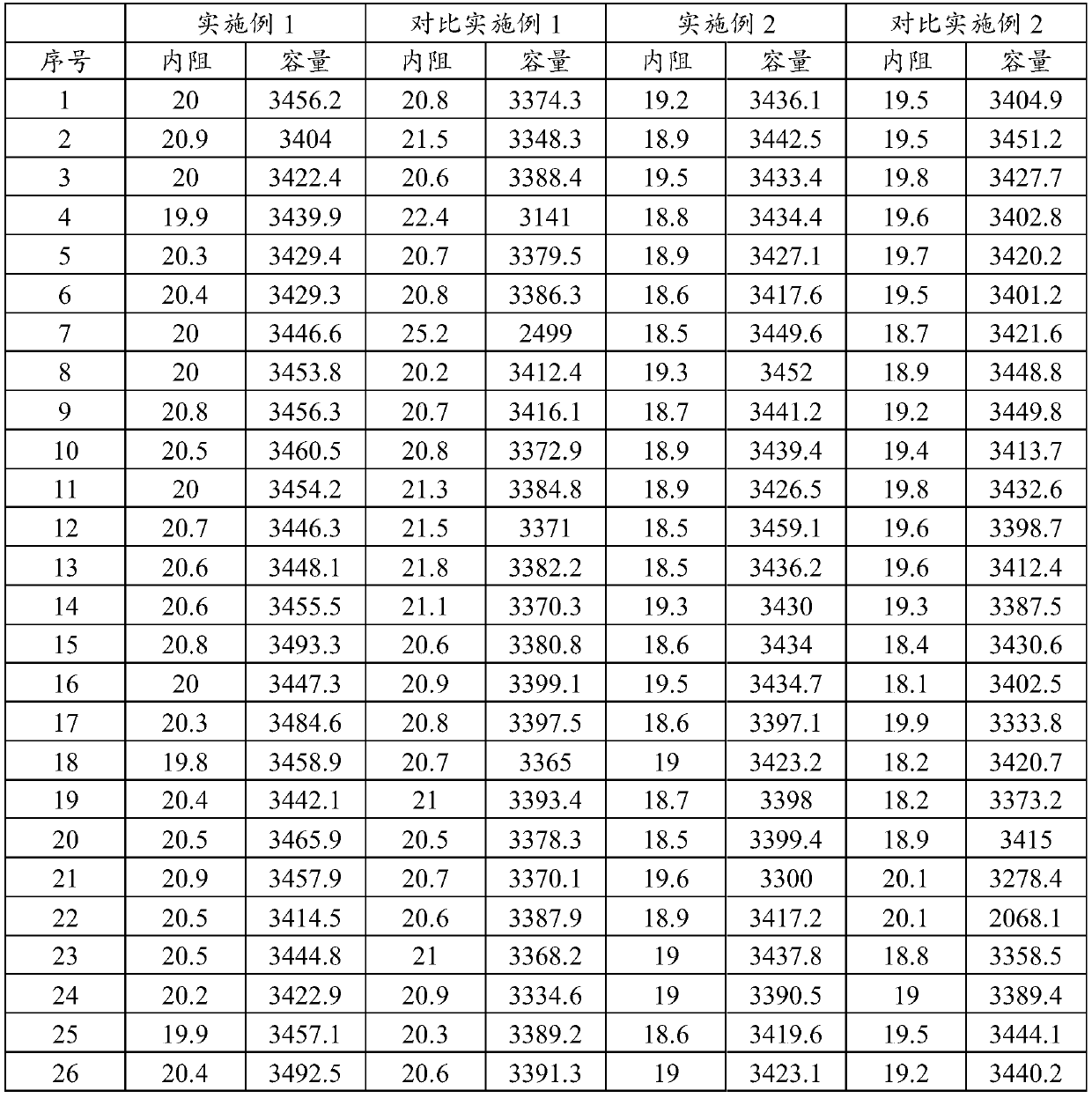

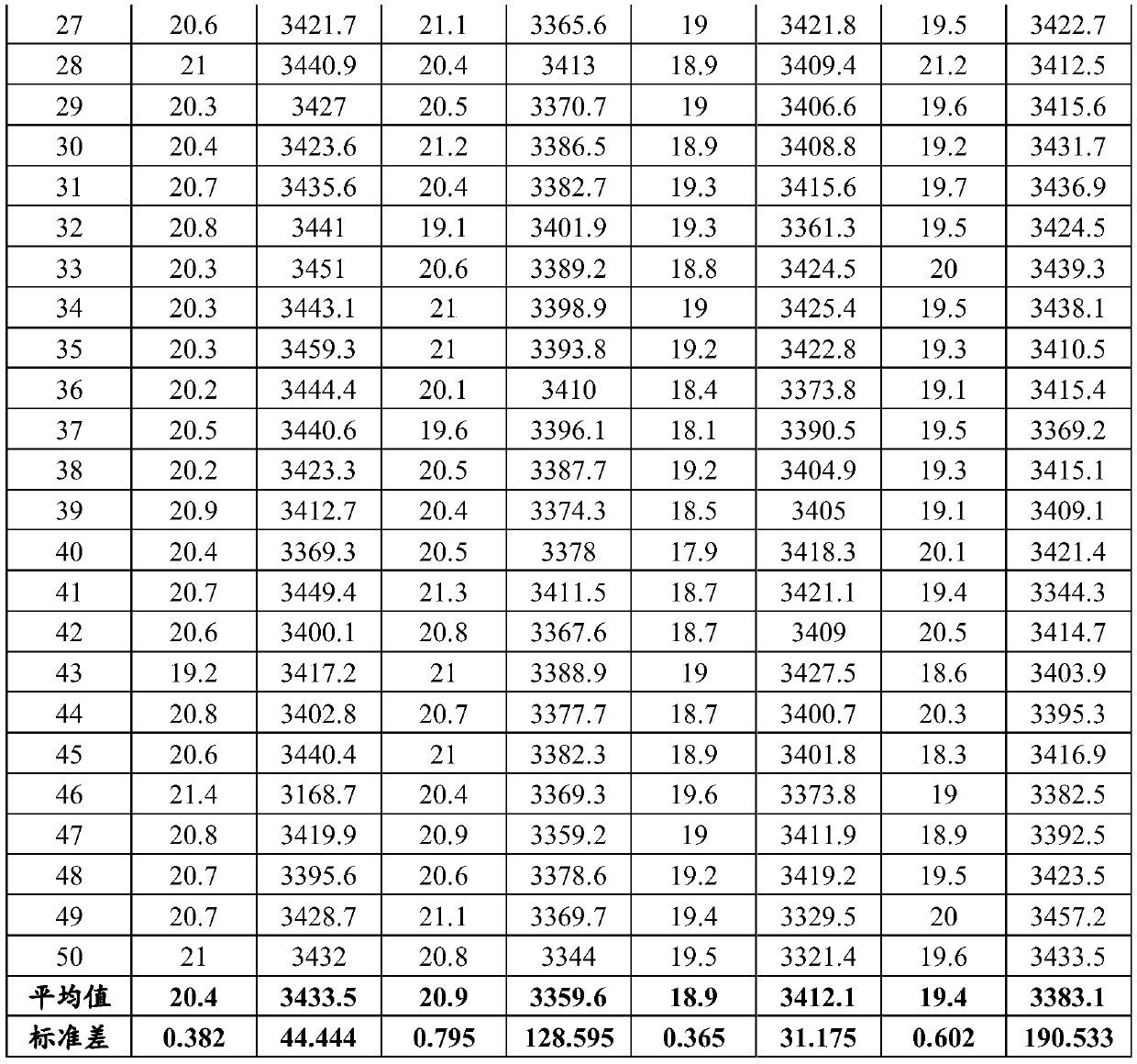

Embodiment 1

[0068] Place the PVDF-HFP coated separator between the positive and negative electrodes, wind it into a flat or oval cell, first preheat it at 60°C for 10 minutes, then shape it at 1Mpa at 60°C for 1min, put it into a steel shell, and inject The electrolyte solution was aged at 45°C for 2 hours, and then formed at room temperature without pressure for 2.5 hours. After volume separation, a high-performance lithium-ion battery was obtained.

Embodiment 2

[0070] Place the acrylic-coated diaphragm between the positive and negative electrodes, and zigzag laminated sheets to form a battery cell. First, preheat it at 80°C for 5 minutes, then shape it at 2MPa 80°C for 1 minute, put it into an aluminum-plastic film package, and inject electrolyte. Aging at 40°C for 4 hours, normal temperature and no pressure for 1.5 hours, and a high-performance lithium-ion battery was obtained after volume separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com