Photo-thermal dual-curing polyolefin packaging adhesive film and preparation method thereof

A technology for encapsulating adhesive films and polyolefins, applied to film/sheet without carrier, adhesives, photovoltaic power generation, etc., can solve problems such as poor appearance, achieve good appearance, reduce poor appearance, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

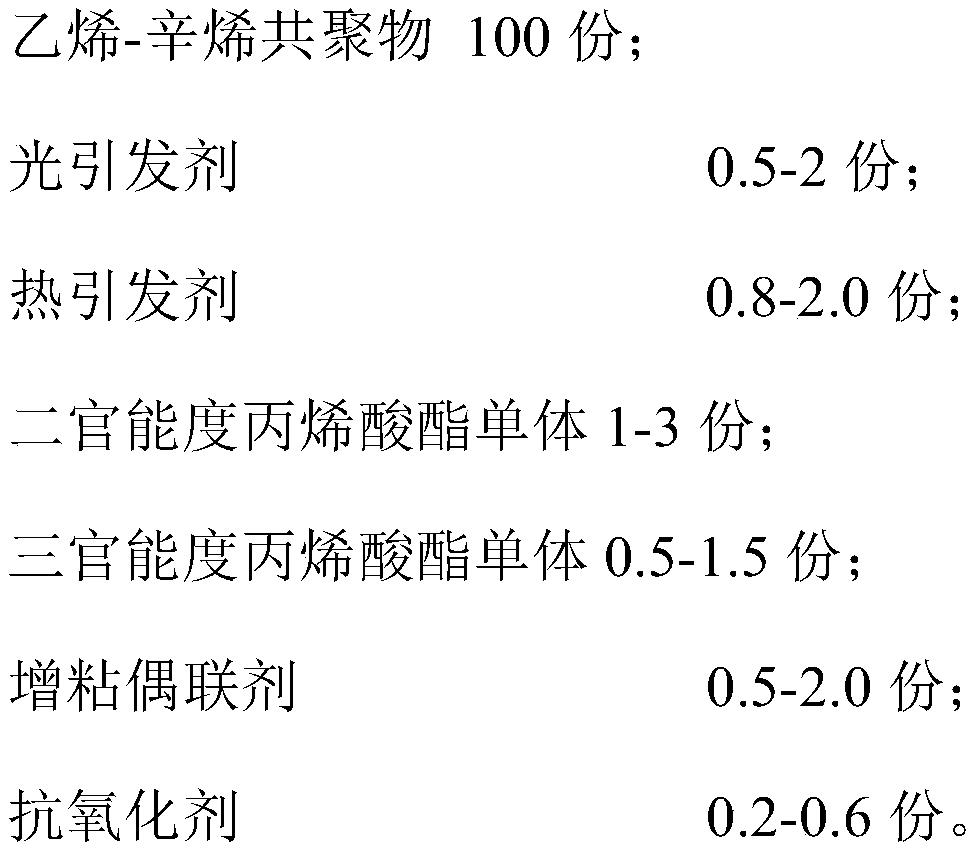

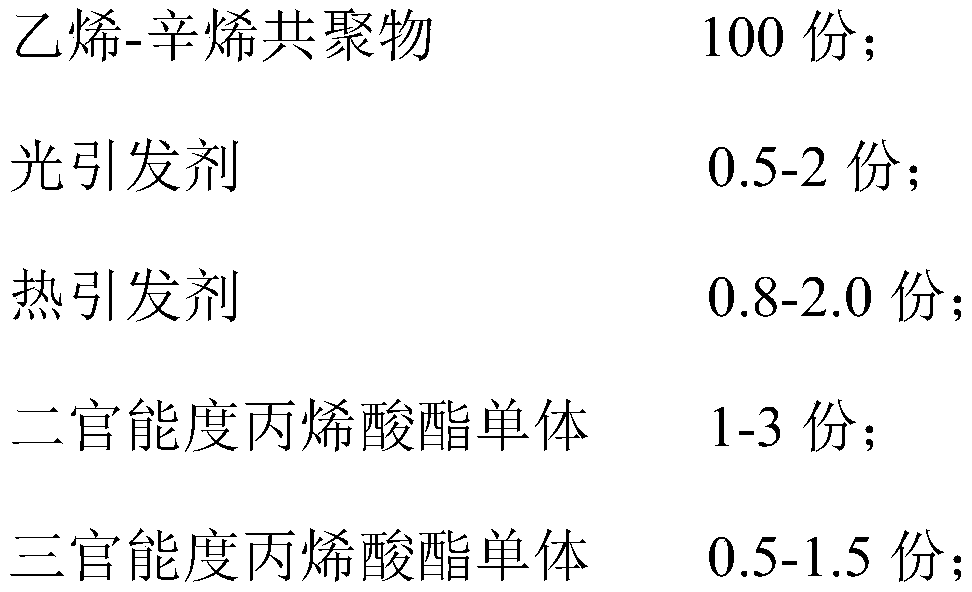

[0029] A photothermal dual-curing polyolefin encapsulation film is prepared from the following components calculated in parts by weight:

[0030] 100 parts of ethylene-octene copolymer;

[0031] 0.5 part of benzophenone;

[0032] 0.8 part of tert-butyl peroxycarbonate-2-ethylhexyl;

[0033] 1 part of tripropylene glycol diacrylate;

[0034] 1.5 parts of triisopropyl isocyanurate;

[0035] 0.5 part of vinyl triethoxysilane;

[0036] 0.2 part of a polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol.

[0037] Among them, the melt index of the ethylene-octene copolymer is 10 g / 10min.

[0038] The preparation method of the above-mentioned photothermal dual-cured polyolefin encapsulation adhesive film comprises the following steps:

[0039] S1. The ethylene-octene copolymer, benzophenone, t-butyl peroxycarbonate-2-ethylhexyl ester, tripropylene glycol diacrylate, triisopropyl isocyanurate, vinyl Triethoxysilane and succinic acid are premixed with a polymer ...

Embodiment 2

[0043] A photothermal dual-curing polyolefin encapsulation film is prepared from the following components calculated in parts by weight:

[0044] 100 parts of ethylene-octene copolymer;

[0045] 1.0 part of thiophenyl-p-oxazapine;

[0046] 2.0 parts of tert-butyl peroxide 2-ethylhexyl carbonate;

[0047] 1.0 part of neopentyl glycol diacrylate;

[0048] 0.8 part of triallyl isocyanurate;

[0049] 2.0 parts of vinyltrimethoxysilane;

[0050] 0.3 part of bis(2,2,6,6-tetramethyl-4-piperidinol) sebacate.

[0051] Among them, the ethylene-octene copolymer melt index is 14g / 10min.

[0052] The preparation method of the above-mentioned photothermal dual-curing polyolefin encapsulation film is the same as that in Example 1, except that the components in step S1 are replaced, the casting temperature in step S2 is adjusted to 100°C, and step S3 is adjusted to a high temperature of 150°C Cured in an autoclave for 12 min to obtain a photothermally cured polyolefin photovoltaic encap...

Embodiment 3

[0054] A photothermal dual-curing polyolefin encapsulation film is prepared from the following components calculated in parts by weight:

[0055] 100 parts of ethylene-octene copolymer;

[0056] 1.3 parts of methyl benzoylformate;

[0057] 1.4 parts of 2-ethylhexyl tert-butyl peroxyformate;

[0058] 2.5 parts of dipropylene glycol diacrylate;

[0059] 1.2 parts of 1,3,5-tri-2-propenyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione;

[0060] 0.7 part of 3-(methacryloyloxy)propyltrimethoxysilane;

[0061] 0.5 part of 1-(methyl)-9-(1,2,2,6,6-pentamethyl-4-piperidine) sebacic acid ester.

[0062] Among them, the melt index of the ethylene-octene copolymer is 16g / 10min.

[0063] The preparation method of the above-mentioned photothermal dual-curing polyolefin encapsulation film is the same as that of Example 1, the difference is that the components of step S1 are replaced, the casting temperature in step S2 is adjusted to 90 ° C, and step S3 is adjusted to be at 155 ° C. After curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com