Degradable carbon felt prepreg and manufacturing process of hood inner plate

A manufacturing process and prepreg technology, which is applied in the field of manufacturing composite material automobile hood inner panels, can solve the problems of increased difficulty in laying composite materials, high cost, and long curing time, and can meet the requirements of low VOC environmental protection and production. High efficiency and good release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

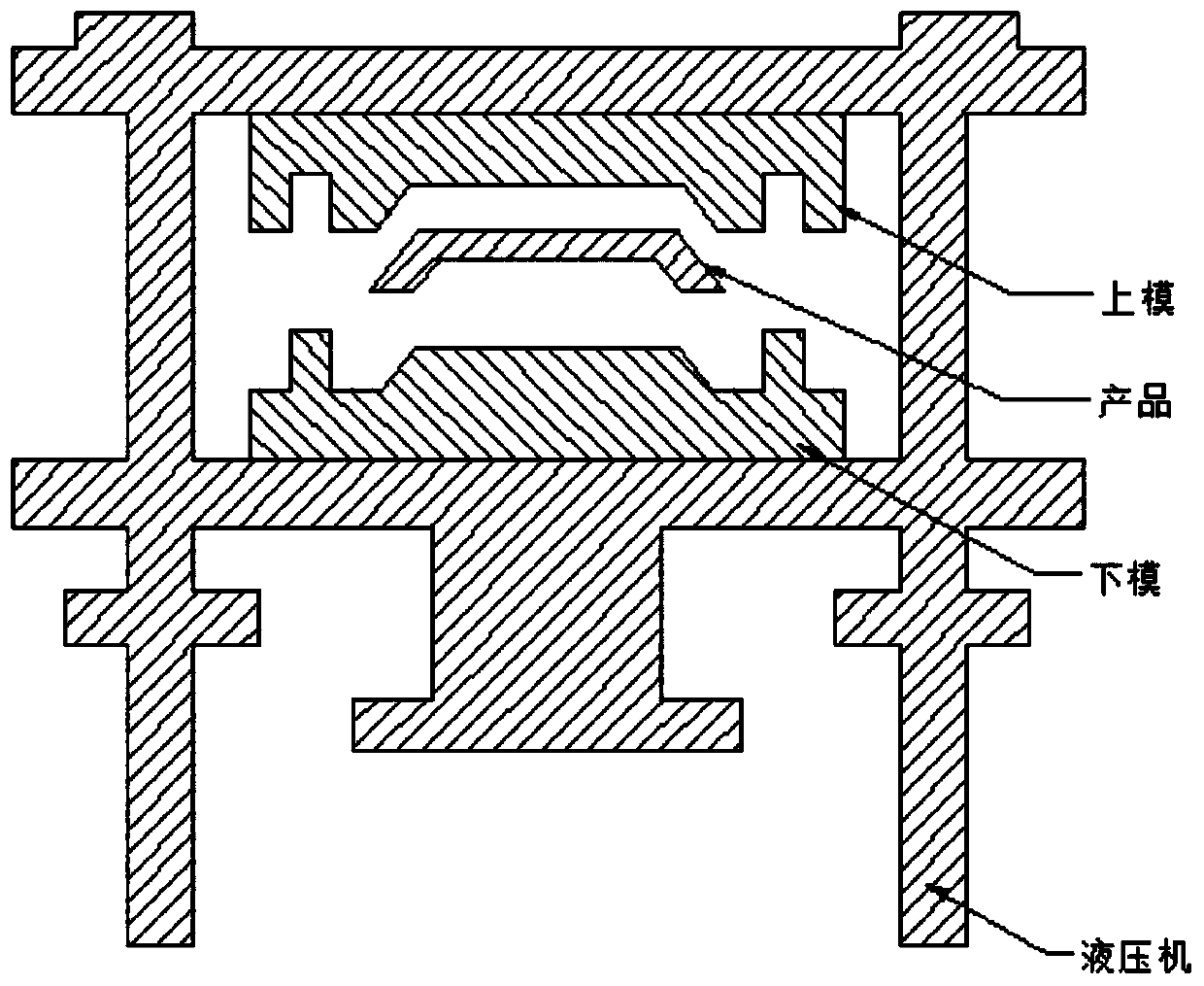

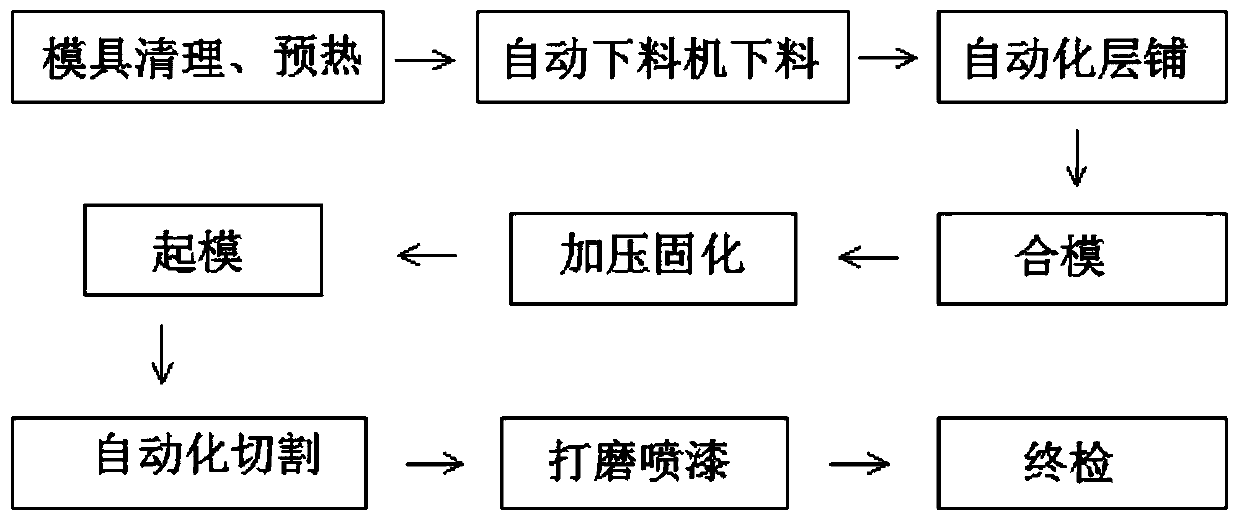

[0027] Such as Figure 1 to Figure 3 Shown, a kind of degradable carbon felt prepreg manufacturing process is characterized in that, comprises the steps:

[0028] Step 1. Add component A of RAF-901 resin to the serial mixer at 900-1200 rpm;

[0029] Step 2: Add component B thickener into the serial mixer and stir evenly to obtain epoxy resin paste;

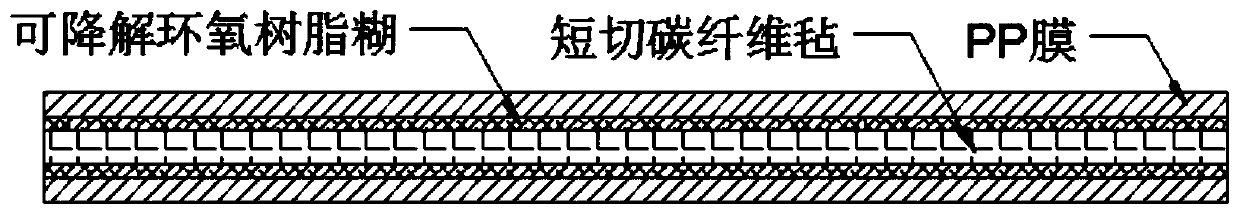

[0030] Step 3: Clean up the RFRT sheet material machine, prepare the PP film, add the mixed epoxy resin paste to the upper and lower glue tanks, turn on the equipment, apply the epoxy resin paste to the inner surface of the upper and lower PP film, and then Composite with chopped carbon fiber mat;

[0031] Step 4: pressurize again, impregnate the carbon fiber felt with resin, and then wind up the resin-impregnated carbon felt with a 6-10-inch inflatable shaft;

[0032] Step 5. Put the carbon fiber felt sheet material prepared above into the drying room for thickening and aging treatment. After the aging treatment is completed, ...

Embodiment 2

[0043] Such as Figure 1 to Figure 3 Shown, a kind of degradable carbon felt prepreg manufacturing process is characterized in that, comprises the steps:

[0044] Step 1. Add component A of RAF-901 resin to the serial mixer at 900-1200 rpm;

[0045] Step 2: Add component B thickener into the serial mixer and stir evenly to obtain epoxy resin paste;

[0046] Step 3: Clean up the RFRT sheet material machine, prepare the PP film, add the mixed epoxy resin paste to the upper and lower glue tanks, turn on the equipment, apply the epoxy resin paste to the inner surface of the upper and lower PP film, and then Composite with chopped carbon fiber mat;

[0047] Step 4: pressurize again, impregnate the carbon fiber felt with resin, and then wind up the resin-impregnated carbon felt with a 6-10-inch inflatable shaft;

[0048] Step 5. Put the carbon fiber felt sheet material prepared above into the drying room for thickening and aging treatment. After the aging treatment is completed, ...

Embodiment 3

[0060] Such as Figure 1 to Figure 3 Shown, a kind of degradable carbon felt prepreg manufacturing process is characterized in that, comprises the steps:

[0061] Step 1. Add component A of RAF-901 resin to the serial mixer at 900-1200 rpm;

[0062] Step 2: Add component B thickener into the serial mixer and stir evenly to obtain epoxy resin paste;

[0063] Step 3: Clean up the RFRT sheet material machine, prepare the PP film, add the mixed epoxy resin paste to the upper and lower glue tanks, turn on the equipment, apply the epoxy resin paste to the inner surface of the upper and lower PP film, and then Composite with chopped carbon fiber mat;

[0064] Step 4: pressurize again, impregnate the carbon fiber felt with resin, and then wind up the resin-impregnated carbon felt with a 6-10-inch inflatable shaft;

[0065] Step 5. Put the carbon fiber felt sheet material prepared above into the drying room for thickening and aging treatment. After the aging treatment is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com