Completely degradable bone repairing material and preparation method thereof

A repair material and bone repair technology, applied in prosthesis, tissue regeneration, medical science, etc., can solve problems such as easy disinfection, and achieve the effect of promoting adhesion, bone regeneration, and bone defect repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

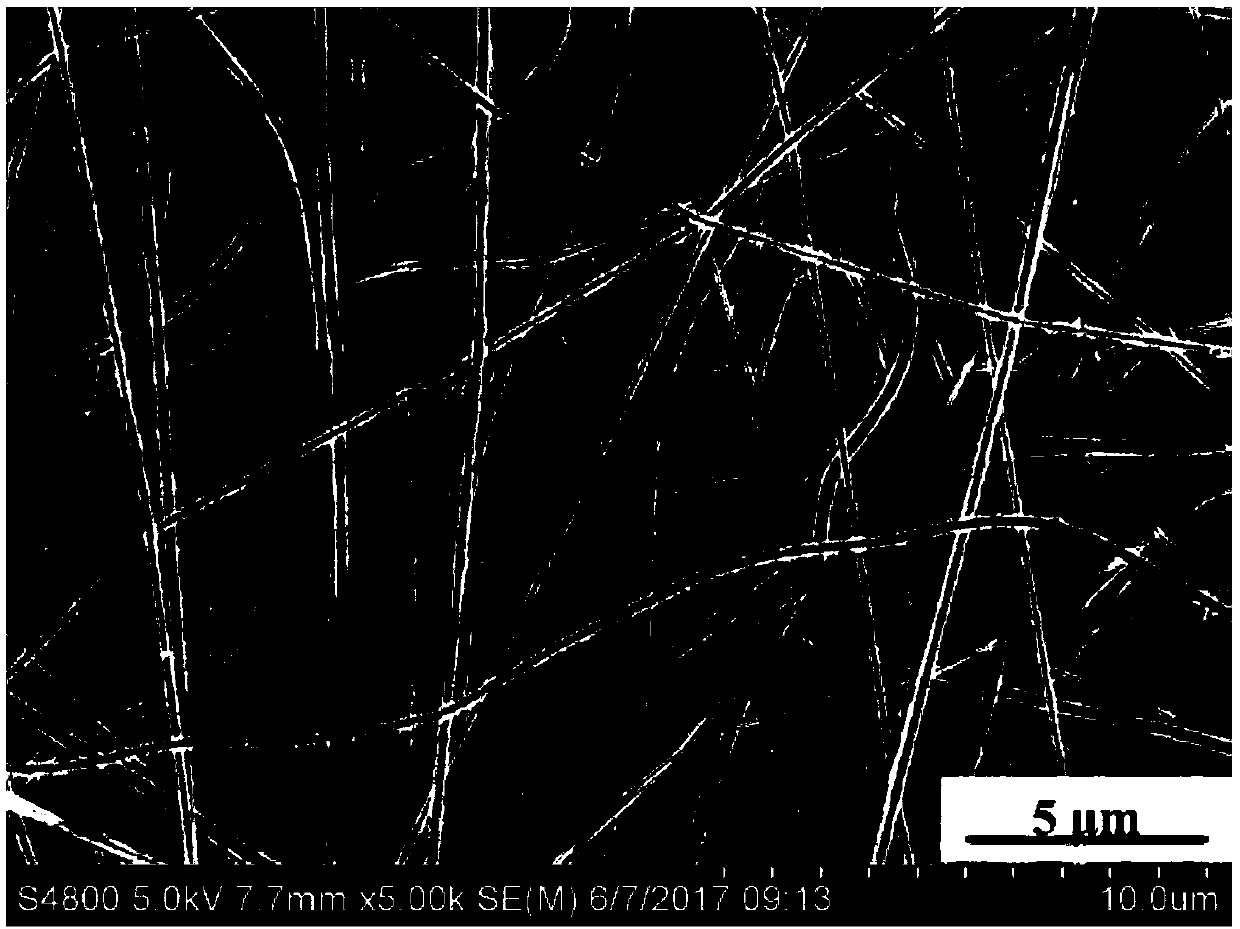

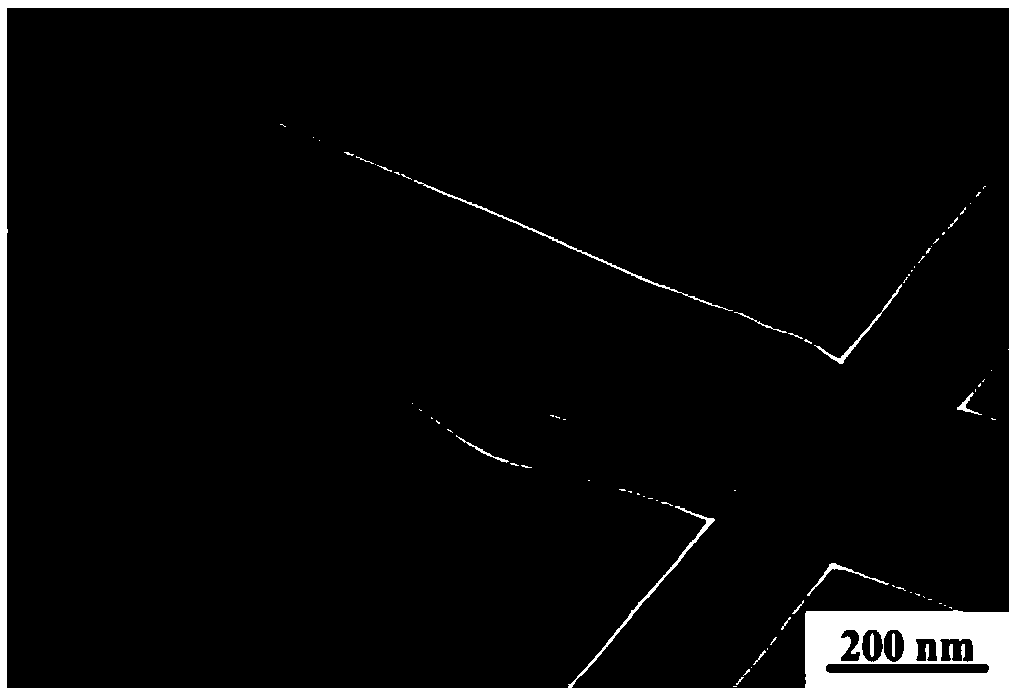

[0055] (1) Take 30 mg of black phosphorus, add 400 mL of N-methylpyrrolidone (NMP) solvent and place it in a cell pulverizer for peeling, the ultrasonic power is 800w, and the solution A is obtained after ultrasonic peeling for 180 minutes;

[0056] (2) Solution A is placed in an ultrasonic machine to continue ultrasonic dispersion, the ultrasonic power is 200w, and the ultrasonic time is 6h, to obtain uniformly dispersed black phosphorus nano-multi-lamellar-NMP solution B;

[0057] (3) Suction filtration is carried out to solution B, and NMP is refluxed, obtains the black phosphorus nanometer multi-sheet C that is dispersed uniformly;

[0058] (4) Take the black phosphorus nano-multi-sheet C and place it in a trifluoroethanol solvent, and fully ultrasonically disperse it to dissolve it to obtain a saturated solution D whose concentration is 2.5 mg / ml;

[0059] (5) 1.08 g of polycaprolactone and 0.72 g of gelatin were dissolved in 28.2 g of trifluoroethanol, and magnetically s...

Embodiment 2

[0064] (1) Take 30 mg of black phosphorus, add 400 mL of N-methylpyrrolidone (NMP) solvent and place it in a cell pulverizer for peeling, the ultrasonic power is 800w, and the solution A is obtained after ultrasonic peeling for 180 minutes;

[0065] (2) Solution A is placed in an ultrasonic machine to continue ultrasonic dispersion, the ultrasonic power is 200w, and the ultrasonic time is 6h, to obtain nano-multi-lamellar-NMP solution B of uniformly dispersed black phosphorus;

[0066] (3) Suction filtration is carried out to solution B, and NMP is refluxed, obtains the black phosphorus nanometer multi-sheet C that is dispersed uniformly;

[0067] (4) Take the nano-multi-sheet C of black phosphorus and place it in a trifluoroethanol solvent, and fully ultrasonically disperse it to dissolve it to obtain a saturated solution D whose concentration is 2.0 mg / ml;

[0068] (5) 1.44 g of polycaprolactone and 0.96 g of gelatin were dissolved in 27.6 g of trifluoroethanol, and magnetic...

Embodiment 3

[0073] (1) Take 30 mg of black phosphorus, add 400 mL of N-methylpyrrolidone (NMP) solvent and place it in a cell pulverizer for peeling, the ultrasonic power is 800w, and the solution A is obtained after ultrasonic peeling for 180 minutes;

[0074] (2) Solution A is placed in an ultrasonic machine to continue ultrasonic dispersion, the ultrasonic power is 200w, and the ultrasonic time is 6h, to obtain uniformly dispersed black phosphorus nano-multi-lamellar-NMP solution B;

[0075] (3) Suction filtration is carried out to solution B, and NMP is refluxed, obtains the black phosphorus nanometer multi-sheet C that is dispersed uniformly;

[0076] (4) Take the black phosphorus nanometer multi-sheet C and place it in a trifluoroethanol solvent, and fully ultrasonically disperse it to dissolve it to obtain a saturated solution D whose concentration is 2.0 mg / ml;

[0077] (5) Dissolve 1.8 g of polylactic acid and 1.2 g of gelatin in 27 g of trifluoroethanol, and stir magnetically at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Vertical size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com