Bionic extracellular matrix bioactive substance coated polyester reticular lamellar stent

A technology of bioactive substances and extracellular matrix, which is applied in the field of biomimetic extracellular matrix bioactive substance-coated polyester mesh sheet scaffolds, can solve the problems of biocompatibility defects and the inability to fundamentally eliminate the influence of shear force , to achieve long-term function maintenance, high porosity and specific surface area, and promote adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present application, and are not construed as limiting the present application.

[0028] This application relates to a bionic extracellular matrix bioactive substance-coated polyester mesh sheet scaffold, which uses bionic extracellular matrix components to construct a microenvironment that simulates the growth of cells in vivo, has good structural stability and mechanical properties, and is suitable for Large-scale three-dimensional culture of adherent cells in vitro can realize large-scale cell culture and promote cell biological activity and function maintenance.

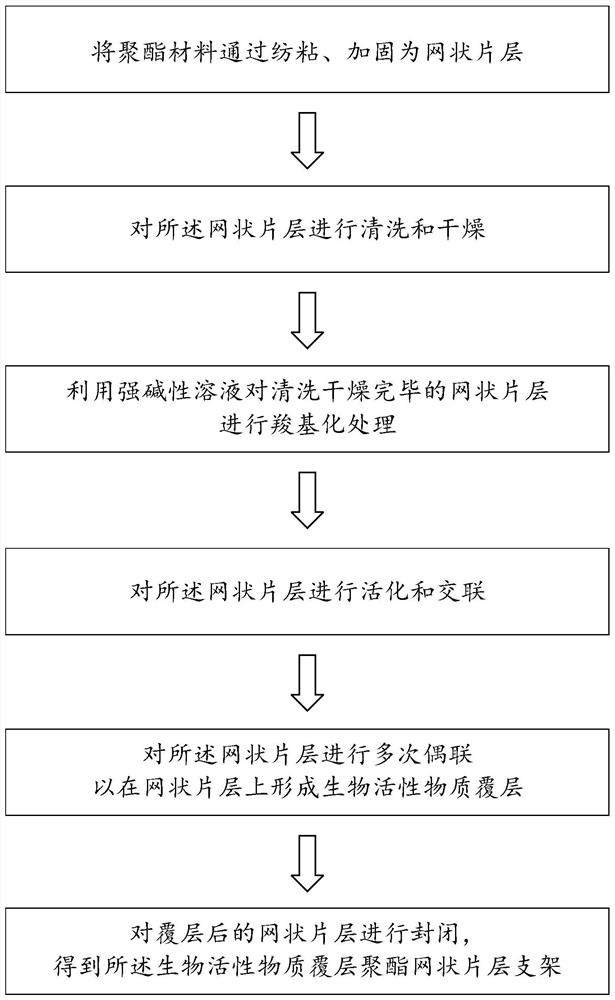

[0029] The biomimetic extracellular matrix biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com