Dried crayfish meat slices and preparation method thereof

A technology for lobster and dried meat, applied in the direction of food science, can solve the problems of increasing defective rate, uneven shape, poor taste, etc., and achieve the effect of reducing pores and promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of dried crayfish meat, comprising:

[0026] A) pretreating the crayfish, and taking the crayfish meat;

[0027] B) Gravity rolling the crayfish meat to obtain the rolled crayfish meat;

[0028] C) mixing the crushed crayfish meat with salt, sugar and transglutaminase, stirring, and marinating to obtain marinated crayfish meat;

[0029] D) spreading the marinated crayfish meat on a bamboo sieve for the first time, and then dehydrating and drying to obtain the once dehydrated and dried crayfish meat;

[0030] E) spreading the crayfish meat after the first dehydration and drying on the bamboo sieve for the second time, and then dehydration and drying to obtain the crayfish meat after the second dehydration and drying;

[0031] F) Roasting the crayfish meat after secondary dehydration and drying, flattening, slicing, cooling, and packaging to obtain dried crayfish meat.

[0032] The invention provides a method for prep...

Embodiment 1

[0073] (1) Crayfish selection: select fresh and live crayfish with uniform individual size, individual weight of 35.0g-40.0g, and net shrimp meat content of 6.0g-8.0g.

[0074] (2) Take the shrimp meat: wash the crayfish, remove the head and the shrimp line, put the shrimp tail in boiling water for 15 seconds, and then remove it.

[0075] (3) Rolling: Gravity crushes the shrimp meat to a thickness of 5.0-8.0 mm, and the muscle fibers of the shrimp meat are naturally loose and connected.

[0076] (4) Pickling: Add 2% salt, 2% sugar, and 2U / g transglutaminase to the processed crayfish meat, mix well, and marinate at 4°C for 2 hours.

[0077] (5) One-time spreading sieve: evenly smear edible vegetable oil on the surface of the bamboo sieve, and spread the marinated crayfish meat on the bamboo sieve, with a thickness of 5.0-8.0mm.

[0078] (6) One-time dehydration and drying: the spread bamboo sieve is placed in an electric blast drying oven at a temperature of 50-60° C., dehydra...

Embodiment 2

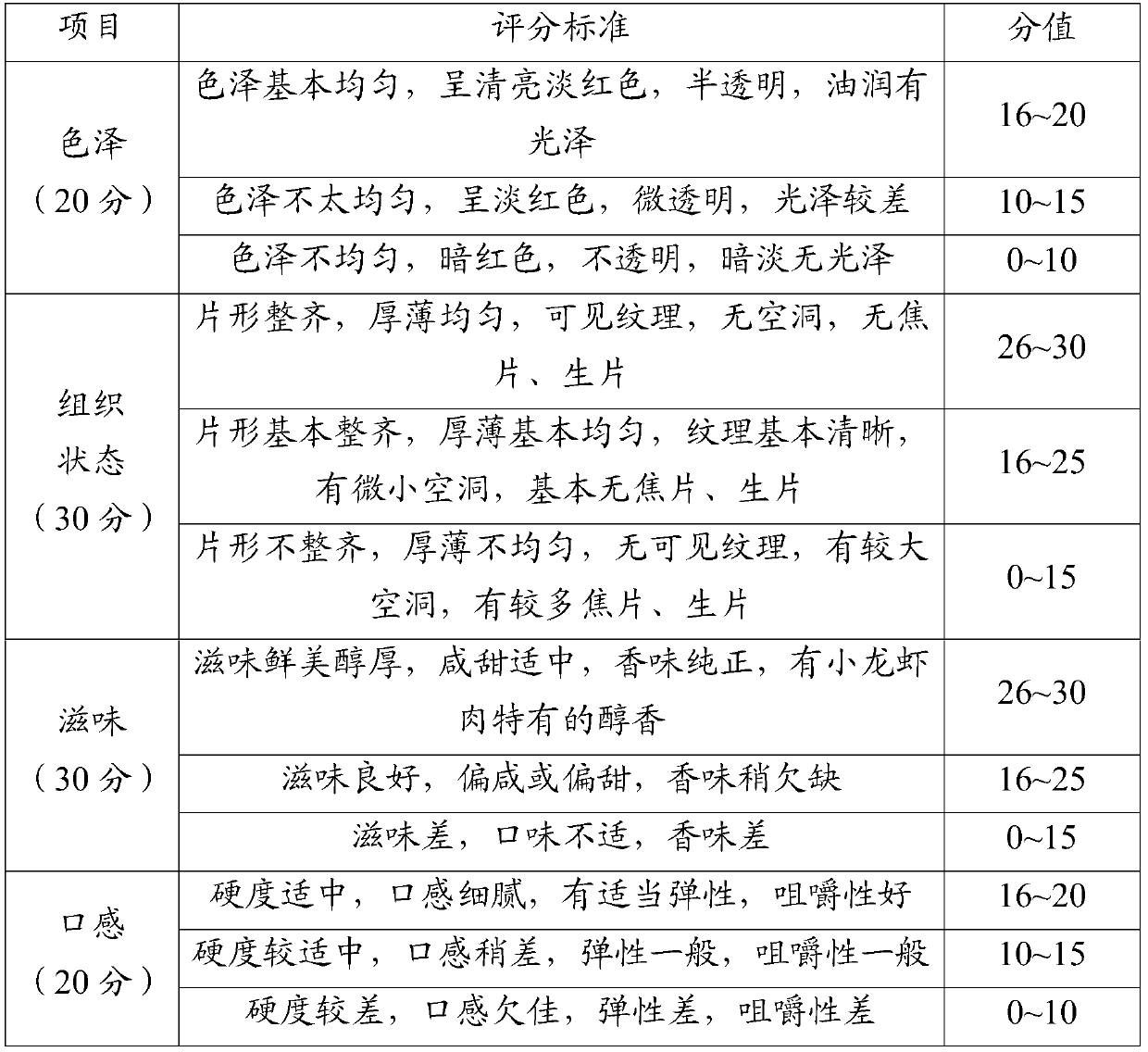

[0123] Evaluation method for the sensory quality of dried crayfish meat: under the guidance of "Guidelines for Sensory Analysis of Food Sensory Quality Control" (GB / T29605-2013), an appraisal team composed of 10 experienced food experts conducted an evaluation of Example 1 and Comparative Example 1. 1. Evaluate the color, texture, taste and mouthfeel of the dried crayfish meat prepared in Comparative Example 2. The weights of each index are 0.2, 0.3, 0.3, 0.2 respectively, and the full score is 100 points, and the average value of 10 expert scores is taken as a scoring result. Table 1 The sensory evaluation criteria of crayfish dried shrimp refer to GB / T31406-2015 dried meat.

[0124] Table 1 Sensory evaluation criteria of crayfish preserved shrimp

[0125]

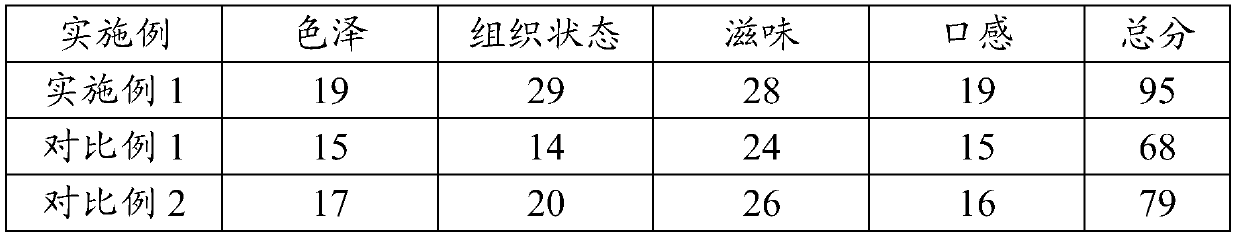

[0126] Table 2 Example 1 and Comparative Example 1, Comparative Example 2, Comparative Example 3 Crayfish Jerky Sensory Evaluation Results

[0127]

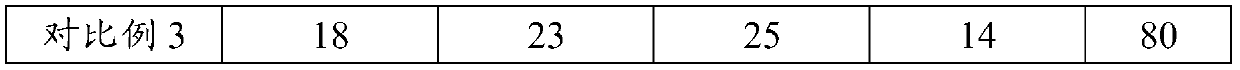

[0128]

[0129] In the present invention, the gravitational ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com