Method for batch production of carbon nanotube fibers

A carbon nanotube fiber, mass production technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of increasing production costs, and achieve the effects of reducing production costs and energy consumption, reducing production costs, and low fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

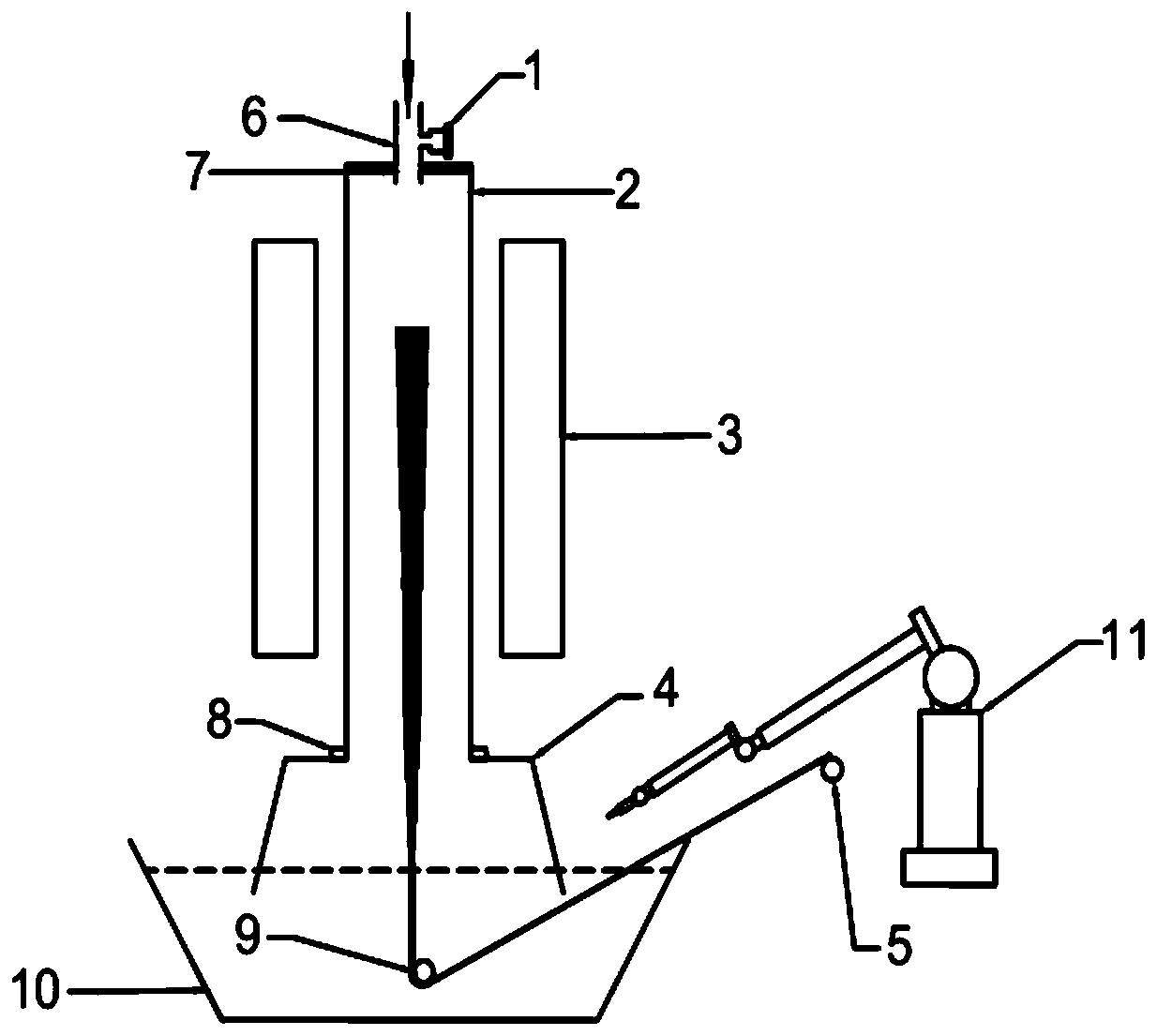

[0036] use as figure 2 The experimental device is a high-temperature reactor using a large quartz tube with three small quartz tubes inside. Carbon nanotube fibers were prepared with ethanol as carbon source, ferrocene as catalyst, thiophene as accelerator, and hydrogen as carrier gas.

[0037] 50g of ethanol, 0.50g of ferrocene, 0.28g of thiophene, and 1g of water were ultrasonically dispersed and mixed, put into a micro syringe, and installed at one end of the reactor. Pass hydrogen into the large quartz tube (2), the gas flow rate is 900ml / min, the temperature of the upper furnace of the tubular resistance furnace (3) is adjusted to 500 ° C, the temperature of the middle and lower furnaces is adjusted to 1170 ° C, and a micro injection pump ( 1) Inject the mixed solution in the syringe into the large quartz tube at a rate of 13.3ml per hour, and crack in area A to produce a white airgel-like mist, which enters into the small In the quartz tube or honeycomb, black translu...

Embodiment 2

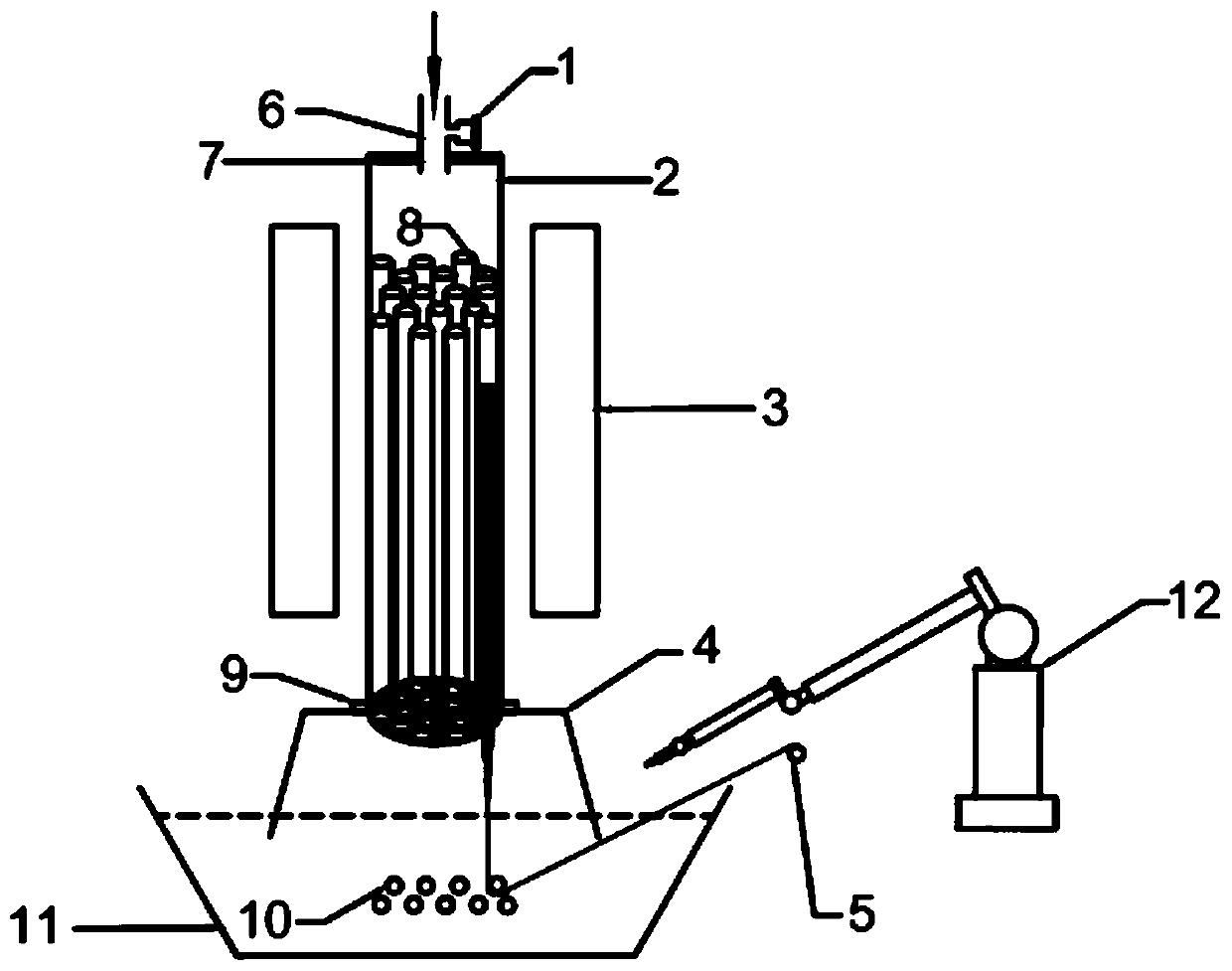

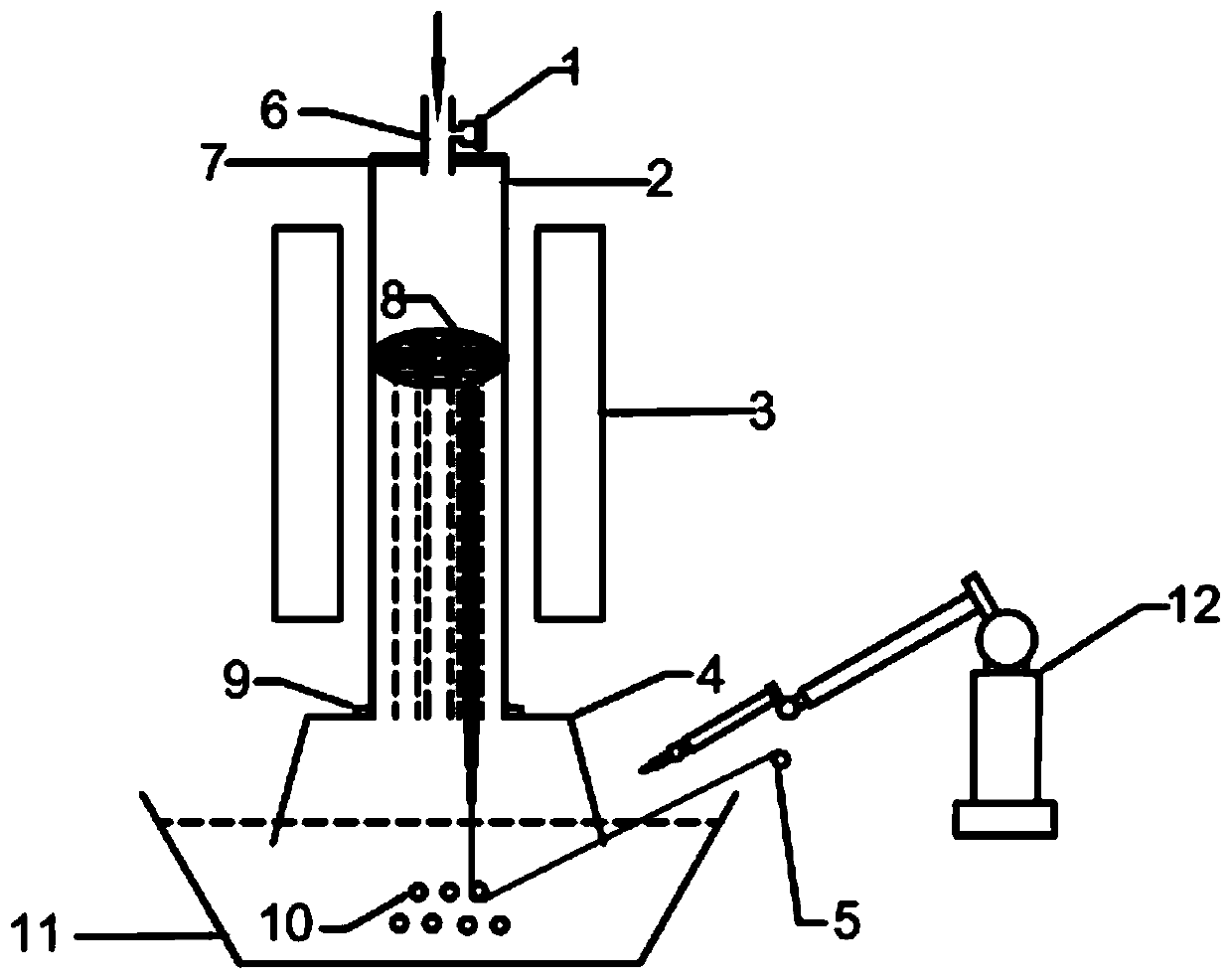

[0039] use as image 3 In the experimental device shown, a large quartz tube with a honeycomb structure is used as a high-temperature reactor, and the number of honeycombs is 5. Carbon nanotube fibers were prepared with ethanol as carbon source, ferrocene as catalyst, thiophene as accelerator, and hydrogen as carrier gas.

[0040] The operation process is the same as that in Example 1. 50 g of ethanol, 0.50 g of ferrocene, 0.28 g of thiophene, and 1 g of water are ultrasonically dispersed and mixed, put into a micro syringe, and installed at one end of the reactor. Pass hydrogen into the large quartz tube (2), the gas flow rate is 900ml / min, the temperature of the upper furnace of the tubular resistance furnace (3) is adjusted to 500 ° C, the temperature of the middle and lower furnaces is adjusted to 1170 ° C, and a micro injection pump ( 1) Inject the mixed solution in the syringe into the large quartz tube at a rate of 13.3ml per hour, and crack in area A to produce a whit...

Embodiment 3

[0042] The process is the same as in Example 1, except that the catalyst is replaced by cobaltocene, and the reaction is carried out under this condition. It is observed that continuous carbon nanotube fibers are formed, and the quality of the obtained fibers is not much different from that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com