Preparation method of TiO2-samarium cuprate nano photocatalysis and electrocatalysis powder

A nanophotonic and electrocatalytic technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unsatisfactory preparation methods, complicated and difficult preparation processes, and poor product performance. , to achieve the effects of nano-sized, strong catalytic effect, and good matching of metal atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the medium takes 1mmol copper acetate and 2mmol samarium acetate, dissolves them in deionized water, the volume consumption of deionized water is 6 times of the total molar mass of copper acetate and samarium acetate, and mixes evenly to obtain solution A;

[0035] (2) Add 3 mmol of acetonitrile to solution A, add 2 mmol of dimethylglyoxime, heat and stir at 60° C. for 2 h to obtain solution B;

[0036] (3) Use a pipette gun to add 5ml of lye with a concentration of 1mol / L (the solute is triethylamine, and the solvent is ethanol), into solution B, stir and dissolve, and prepare solution C.

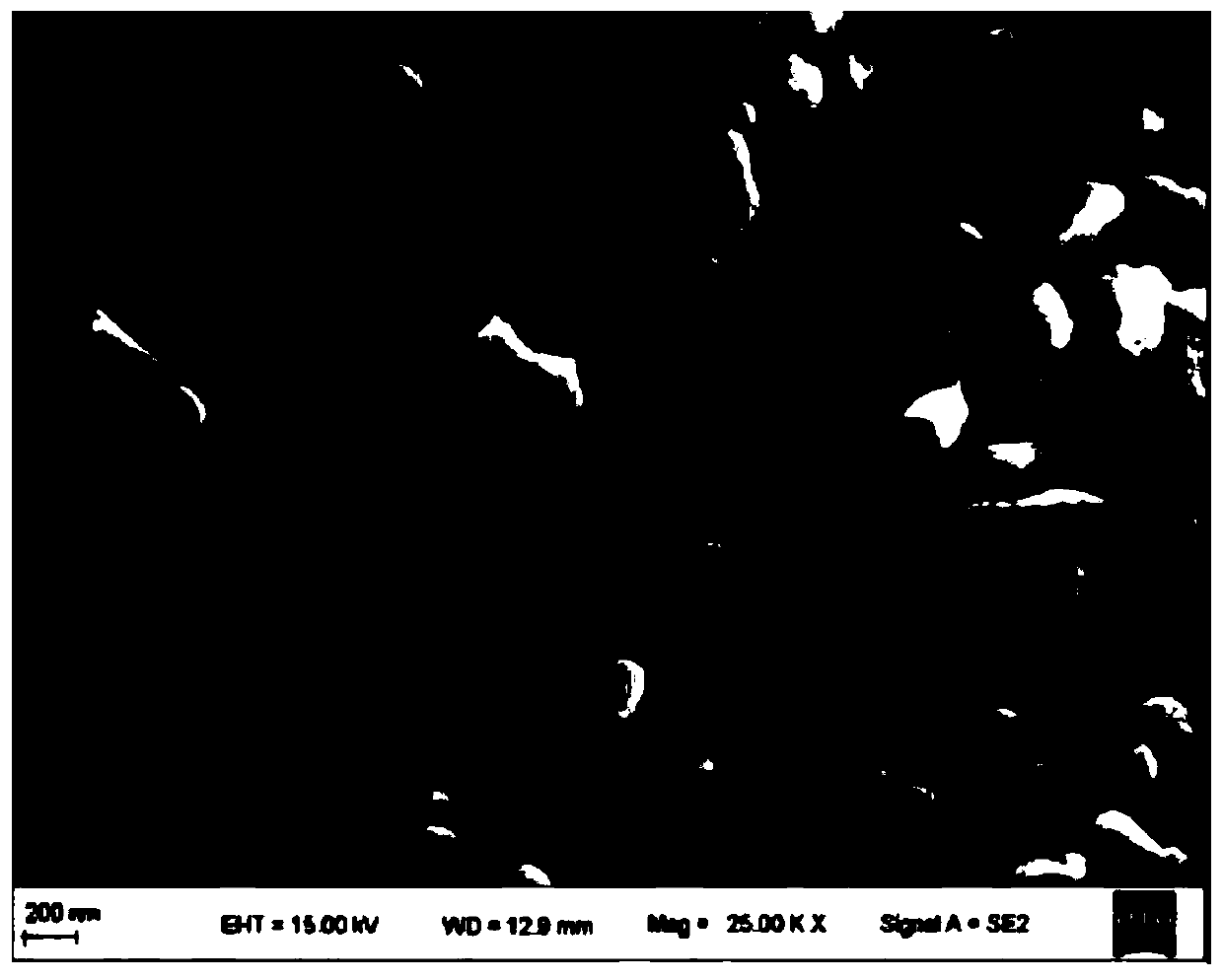

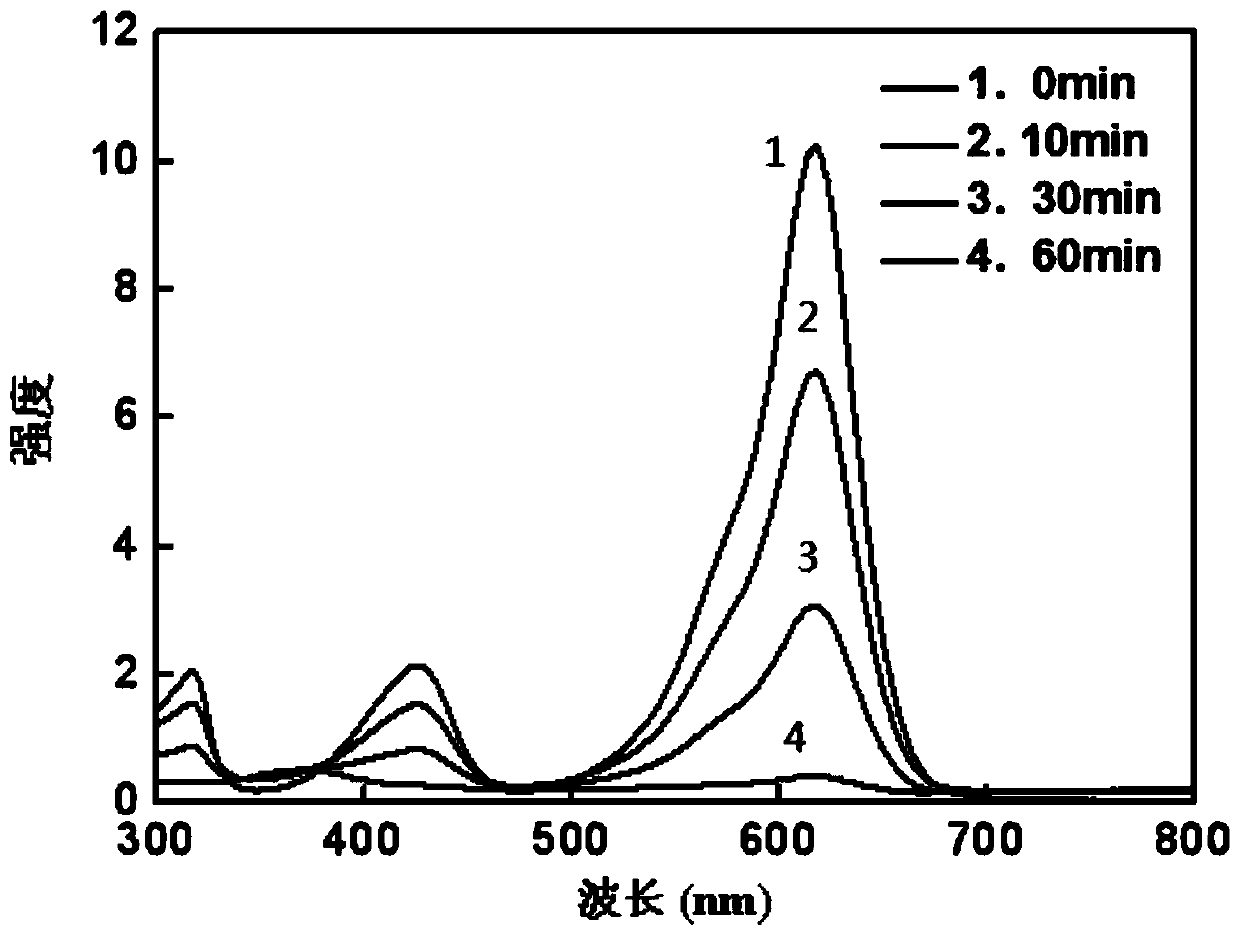

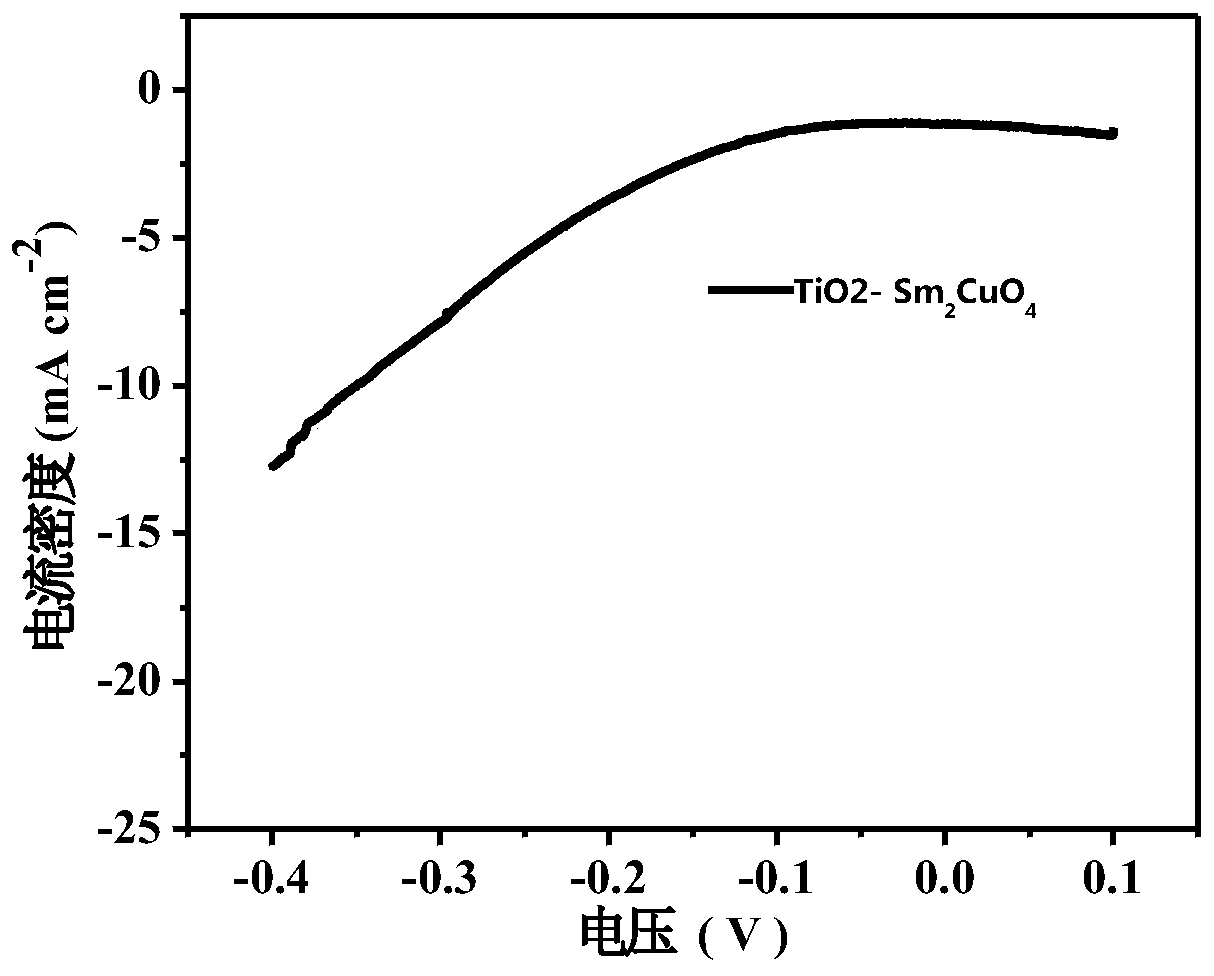

[0037] (4) Put solution C into an oven, and react at a constant temperature for 3 hours at a temperature of 120° C., then cool to room temperature in the air; after the solution system is stable, filter the resulting mixed solution, and wash the resulting solid with water twice, The obtained crys...

Embodiment 2

[0041] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the middle takes 1mmol copper nitrate and 2mmol samarium nitrate, dissolves them in deionized water, the volume consumption of deionized water is 6 times of the total molar mass of copper nitrate and samarium nitrate, mixes evenly, obtains solution A;

[0042] (2) Add 4 mmol of acetonitrile to solution A, add 2 mmol of dimethylglyoxime, heat and stir at 80° C. for 2.5 h to obtain solution B;

[0043] (3) Use a pipette gun to add 5ml of lye with a concentration of 1mol / L (the solute is triethylamine, and the solvent is ethanol) into solution B, stir until dissolved, and prepare solution C.

[0044] (4) Put solution C into an oven, and react at a constant temperature for 4 hours at a temperature of 150° C., then cool to room temperature in the air; after the solution system is stable, filter the resulting mixed solution, and wash the resulting solid with water for 3 times, The obtained...

Embodiment 3

[0050] (1) According to samarium cuprate Sm 2 CuO 4 The stoichiometric ratio of Cu and Sm in the middle takes by weighing 1mmol cupric chloride and 2mmol samarium chloride, is dissolved in deionized water, and the volume consumption of deionized water is 5 times of the total molar mass of cupric chloride and samarium chloride, mixes evenly, Obtain solution A;

[0051] (2) Add 9 mmol of acetonitrile to solution A, add 3 mmol of dimethylglyoxime, heat and stir at 80° C. for 2 h to obtain solution B;

[0052] (3) Use a pipette gun to add 5ml of lye with a concentration of 1mol / L (the solute is triethylamine, and the solvent is ethanol) into solution B, stir until dissolved, and prepare solution C.

[0053] (4) Put solution C into an oven, and react at a constant temperature for 6 hours at a temperature of 130° C., then cool to room temperature in the air; after the solution system is stable, filter the resulting mixed solution, and wash the resulting solid with water 4 times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com