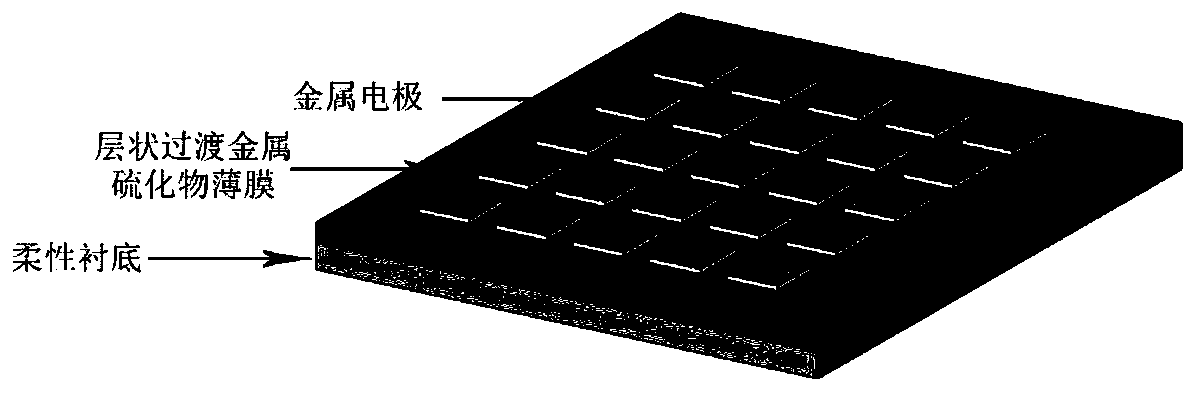

Flexible photoelectric detector based on layered transition metal sulfide and preparation method thereof

A photodetector and transition metal technology, applied in the field of microelectronics, can solve the problems of difficult control of the distance of the metal electrode channel, irregular pattern of the patterned metal electrode, uneven thickness of the photosensitive film, etc., and achieves low cost and simple preparation process. , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

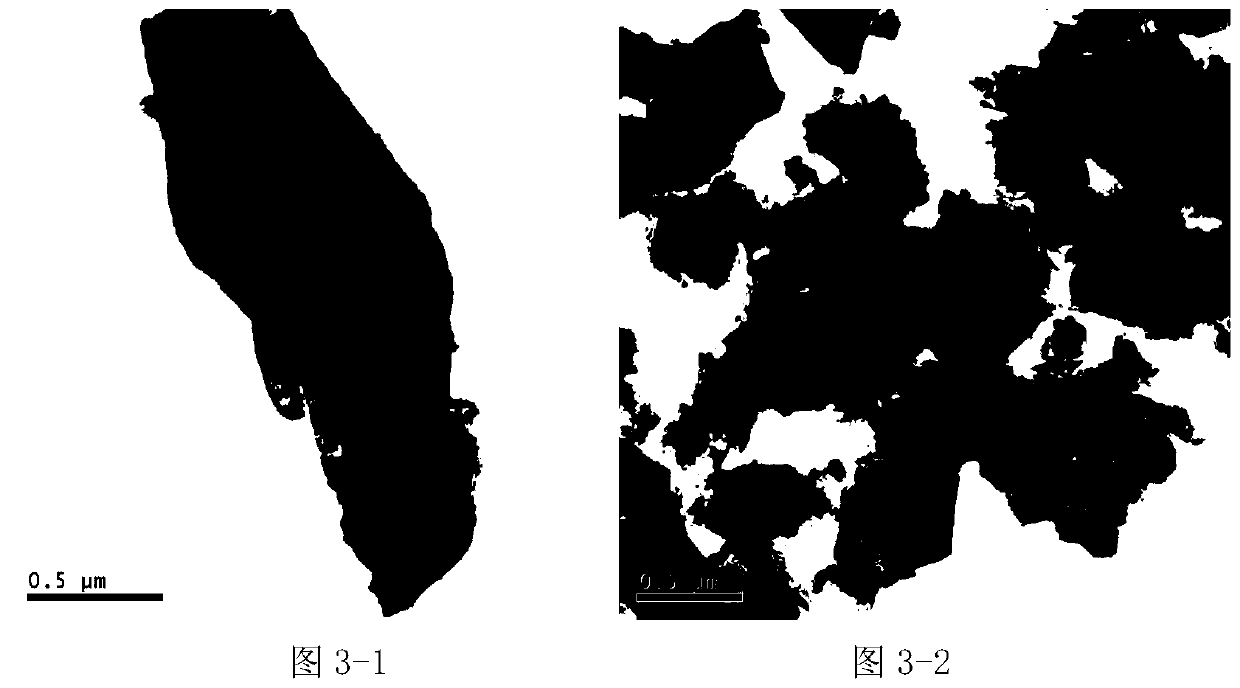

[0079] 1) MoS prepared by physical vapor deposition 2 (Shanghai Aladdin Biochemical Technology Co., Ltd.), isopropanol, and ethyl cellulose are configured in a polytetrafluoroethylene planetary ball mill jar with a capacity of 100ml according to the ratio of 1g: 10ml: 0.1g;

[0080] 2) Add 10 agate grinding balls with a diameter of 10mm and 70 agate balls with a diameter of 5mm, and put them into a planetary ball mill for sealing;

[0081] 3) Adjust the rotational speed of the ball mill to 300r / min, use the forward rotation for 25min, stop for 5min, reverse for 25min, stop for 5min, cycle operation mode, and ball mill for 72h to obtain MoS 2 suspension;

[0082] 4) Cut the flexible PET into a square of 1cm×1cm, ultrasonically clean it with absolute ethanol and deionized water for 10 minutes, and dry it with a nitrogen gun to obtain a flexible PET substrate;

[0083] 5) The flexible PET substrate is vacuum-adsorbed at the center of the homogenizer, and the speed of the homoge...

Embodiment 2

[0092] 1) WS prepared by supersonic jet milling 2 (Shanghai Aladdin Biochemical Technology Co., Ltd.), isopropanol, and ethyl cellulose are configured in a polytetrafluoroethylene planetary ball mill jar with a capacity of 100ml according to the ratio of 1.55g: 10ml: 0.1g;

[0093] 2) Add 10 agate grinding balls with a diameter of 10mm and 75 agate balls with a diameter of 5mm, and put them into a planetary ball mill for sealing;

[0094] 3) Adjust the rotational speed of the ball mill to 200r / min, use the forward rotation for 20min, stop for 8min, reverse for 20min, stop for 8min, cycle operation mode, ball mill for 80h, and get WS 2 suspension;

[0095]4) Cut the flexible PVC into a square of 1cm×1cm, ultrasonically clean it with absolute ethanol and deionized water for 10 minutes, and dry it with a nitrogen gun to obtain a flexible PVC substrate;

[0096] 5) Vacuum absorb the flexible PVC substrate at the center of the homogenizer, set the speed of the homogenizer to 3000...

Embodiment 3

[0105] 1) Preparation of MoS by hydrothermal method 2 For flower-shaped nanospheres, dissolve 4mmol ammonium paramolybdate and 6.3mmol thiourea in 30ml deionized water, use concentrated hydrochloric acid to adjust the pH value to 2, seal it in a high-pressure reactor, and react at 200°C for 24h to obtain water Thermally prepared MoS 2 ;

[0106] 2) MoS 2 , isopropanol, and ethyl cellulose are configured in a polytetrafluoroethylene planetary ball mill jar with a capacity of 100ml according to the ratio of 1g: 10ml: 0.1g;

[0107] 3) Add 10 agate grinding balls with a diameter of 10mm and 70 agate balls with a diameter of 5mm, and put them into a planetary ball mill for sealing;

[0108] 4) Adjust the rotational speed of the ball mill to 450r / min, use the forward rotation for 30min, stop for 10min, reverse for 30min, stop for 10min, cycle operation mode, and ball mill for 3h to obtain MoS 2 suspension;

[0109] 5) Cut the flexible PI into a square of 1cm×1cm, ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com