A method and system for measuring pn junction depth of indium antimonide material

An indium antimonide, PN junction technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of complex process implementation, long cycle, long process time, etc., to simplify the measurement operation process, reduce Measurement cost, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

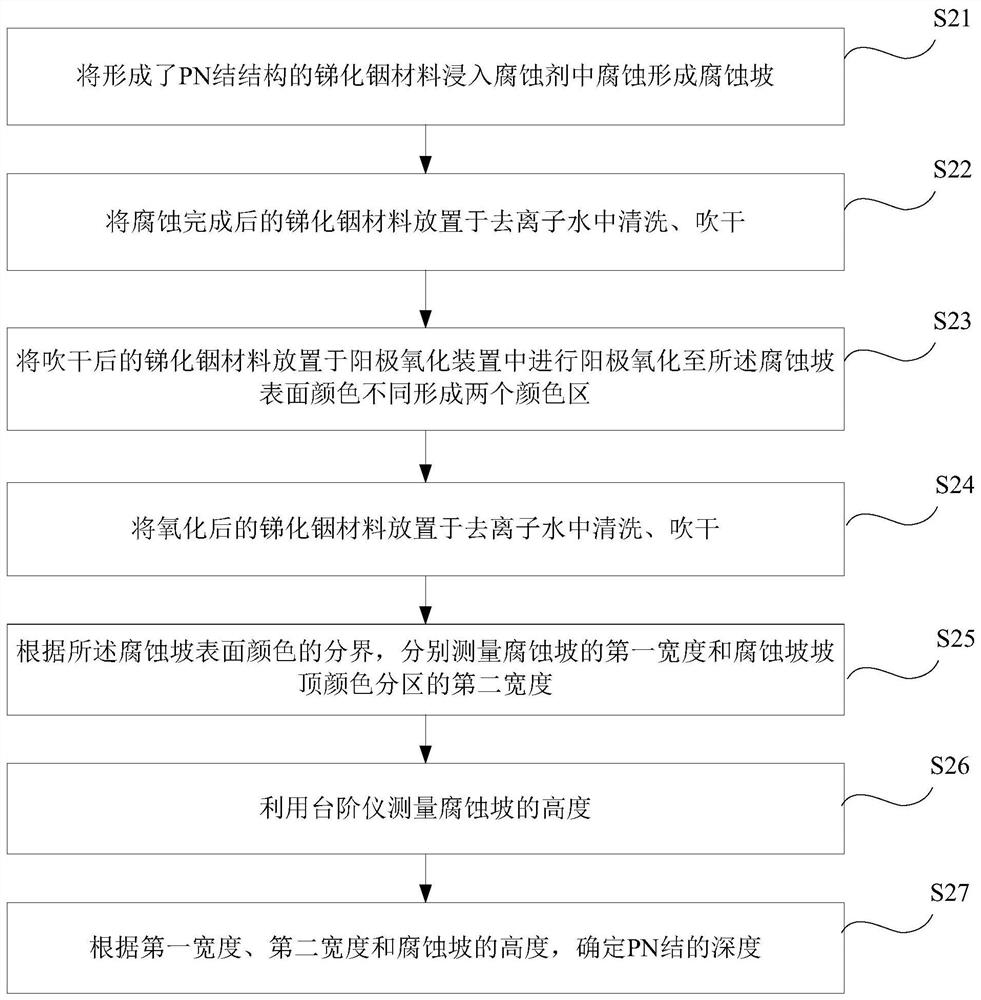

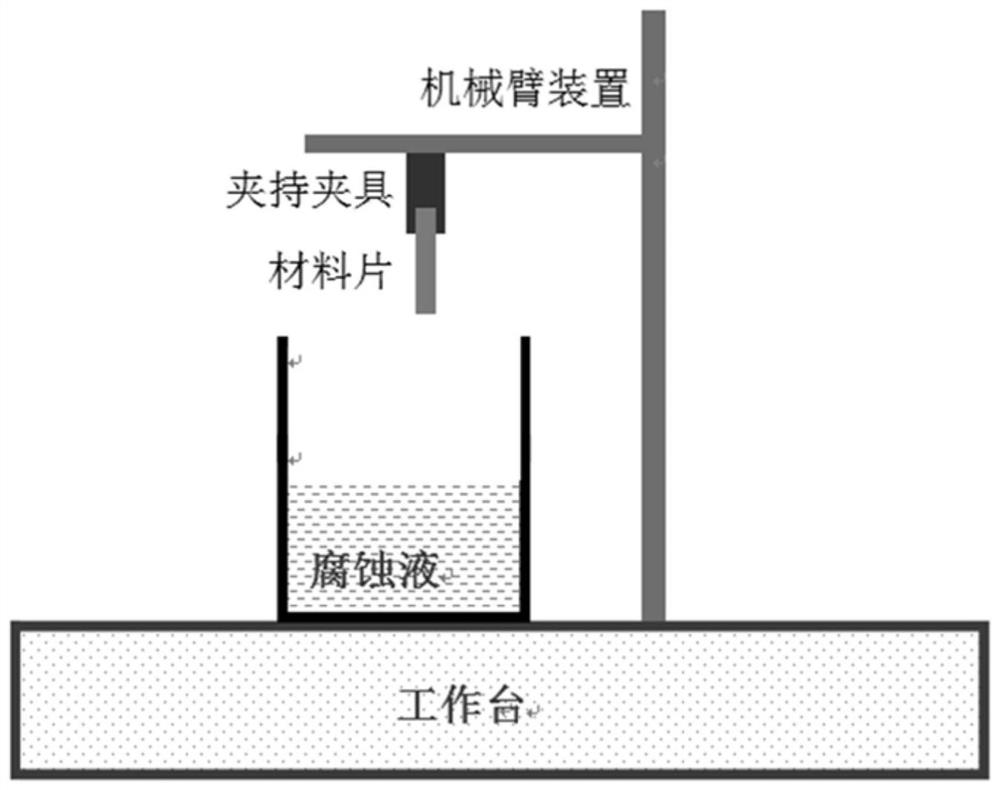

[0049] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0050] First, some terms involved in the embodiments of the present invention are described to facilitate the understanding of those skilled in the art.

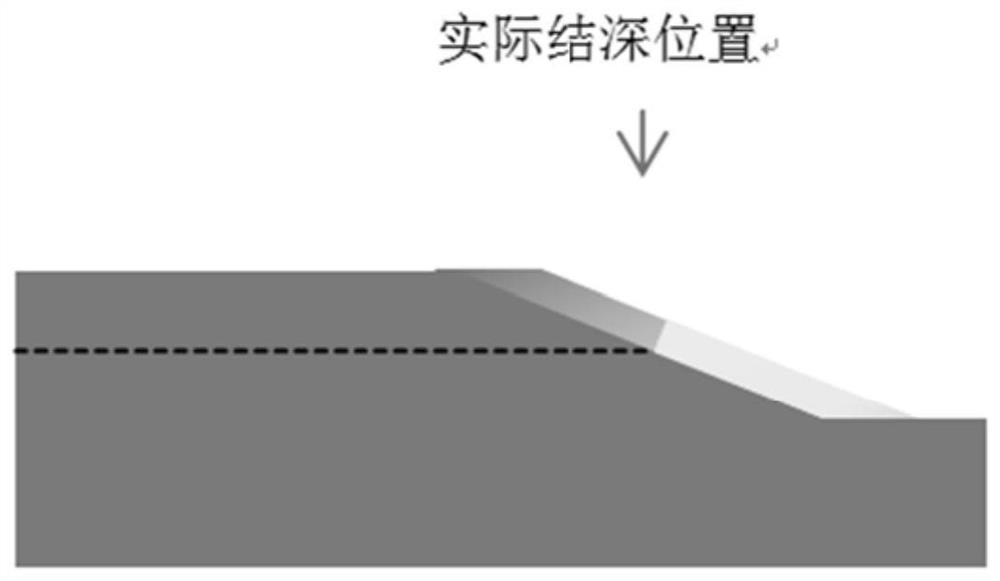

[0051] PN junction: Different doping processes are used to combine P-type semiconductors (P is the prefix of Positive, which is named because the holes are positively charged) and N-type semiconductors (N is the prefix of Negative, due to the effect of diffusion) Electrons are negatively charged to get this name) are fabricated on the same semiconductor (usually silicon or germanium) substrate, and a space charge region is formed at their interface called a PN junction. The PN junction has unidirectional conductivity, which is a characteristic used by many devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com