A processing technology for producing refractory board from modified kraft paper

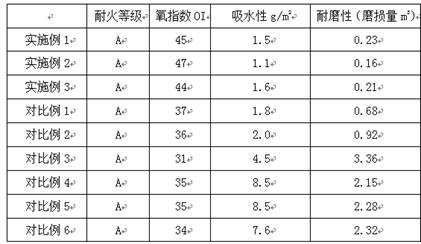

A processing technology and technology of kraft paper, which can be used in the addition of fire retardants, papermaking, paper, etc., can solve the problems of reducing the fire resistance of refractory boards, low service life of refractory boards, and prone to cracks, etc., to improve service life, excellent fire resistance and The effect of abrasion resistance and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A modified kraft paper produces fire-resistant sheet processing processes, and the specific processing methods are as follows:

[0030] 1) Production of modified kraft paper

[0031] S1, 1 part of the polyethylene glycol, added to 30 parts of deionized water, stirred and dissolved, 3 parts of high polymerization zone, 2 parts of pentaerythyl alcohol, 1 melamine, mixed, mix well, then ground 1 h, then join 15 parts of acrylic resin, 10 urea resins, 1 polydimethylsiloxane, continued to ground 2 h, then add 2 sodium dodecyl benzene sulfonate, and emulsified at 10,000 R / min with a high speed emulsifier for 8 min. Refractory emulsion;

[0032]S2, the kraft paper is deesed, and the pulverizer is pulverized after the pulverizer is passed, and the plant fiber slurry having a solution of 15 ° SR is obtained. Dehydration to a water content of 40%, and the water is low-temperature at -20 ° C under -20 ° C. After 30 h, the room temperature was balanced at the end of the frozen, and t...

Embodiment 2

[0048] A modified kraft paper produces fire-resistant sheet processing processes, and the specific processing methods are as follows:

[0049] 1) Production of modified kraft paper

[0050] S1, 1.5 parts of polyethylene glycol, add 40 parts of deionized water, stirred and dissolved, 4 parts of high polymerization zone, 3 parts of the pentaerythyl alcohol, 1.5 parts of melamine, mixed, mix well, then ground 1.5 h on the ball mill, then An acrylic resin was added, 13 parts of urea resin, and 1.5 parts of polydimethylsiloxane were added, and 2.5 parts of sodium dodecyl benzene sulfonate was added, and 7Min was emulsified under 11000 r / min with a high speed emulsifier. Refractory emulsion;

[0051] S2, the kraft paper is deesed, and the pulverizer is pulverized after the pulverizer is bleached, and the plant fiber slurry with a dummy is 18 ° SR is obtained. Dehydration to a water content of 45%, and the balance is 15 h after -40 ° C low temperature freezing treatment. At 25h, the ro...

Embodiment 3

[0067] A modified kraft paper produces fire-resistant sheet processing processes, and the specific processing methods are as follows:

[0068] 1) Production of modified kraft paper

[0069] S1, 2 parts of polyethylene glycol, added to 50 parts of deionized water, and then dissolve 5 parts of high polymerization zone, 4 parts of pentaerythol, 2 parts of pentaerythrol, and mix hard, mix well in the ball mill, then joined 20 parts of the acrylic resin, 15 parts of urea resin, 2 parts of polydimethylsiloxane, continued to ground 3 parts of sodium dodecyl benzene sulfonate, and emulsified at 13000 r / min with a high speed emulsifier for 5 min. Refractory emulsion;

[0070] S2, delamination of kraft paper, pulverized after the pulverizer is pulverized, then obtaining a plant fiber slurry of 20 ° SR by the grinding, dehydration to a water content of 50%, equilibrium at -50 ° C low temperature freezing treatment At 20 h, the room temperature was 25 h after freezing, and then the crystali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com