A kind of synthetic method of cubic boron nitride

A cubic boron nitride and synthesis method technology, applied in chemical instruments and methods, ultra-high pressure process, single crystal growth, etc., can solve the problem of thermal shock toughness decline, catalytic performance decline, and affect the conversion rate of cubic boron nitride and other problems, to achieve the effect of complete crystal form and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of synthetic method of cubic boron nitride, concrete process is as follows:

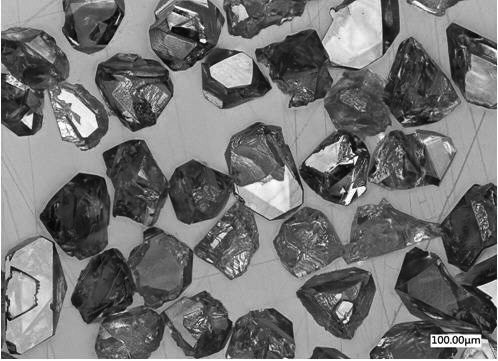

[0019] LiAlH 4 Powder, Li 3 N powder and Li 3 BN 2 Powder is catalyst, and commercially available hBN is raw material (BN content 99.0wt%, B 2 o 3 0.3wt%), by mass ratio LiAlH 4 : Li 3 N: Li 3 BN 2 : hBN=2︰4︰8︰100 The ratio is to take the materials separately, mix them evenly and press them into a cylinder, put them into a graphite heating tube to make a composite rod, assemble them with pyrophyllite and other components to form an assembly block, and put the assembly block into six In the synthesis cavity of the surface-top press, pressurize to 5.2GPa, keep the temperature for 8 minutes after the temperature reaches 1450°C, stop heating after the synthesis, wait for 3 minutes and then release the pressure. The composition was taken out, crushed, soaked in water, and treated with conventional acid and alkali to obtain pure cubic boron nitride, and sieved with a sieve to obtain ...

Embodiment 2

[0021] A kind of synthetic method of cubic boron nitride, concrete process is as follows:

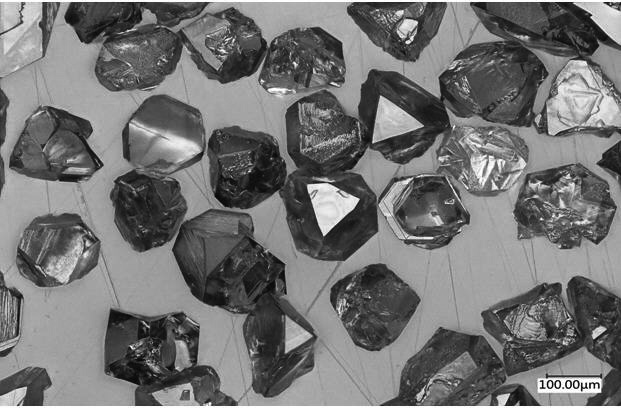

[0022] LiAlH 4 Powder, Li 3 N powder and Li 3 BN 2 Powder is catalyst, and commercially available hBN is raw material (BN content 98.5wt%, B 2 o 3 0.4wt%), by mass ratio LiAlH 4 : Li 3 N: Li 3 BN 2 : hBN=5︰9︰6︰100 The ratio is to take the materials separately, mix them evenly and press them into a cylinder, put them into a graphite heating tube to make a composite rod, assemble them with pyrophyllite and other components to form an assembly block, and put the assembly block into six In the synthesis cavity of the surface-top press, pressurize to 5GPa, and keep the temperature at 1500°C for 10 minutes. After the synthesis, stop heating first, and wait for 3 minutes before releasing the pressure. The composition was taken out, crushed, soaked in water, and treated with conventional acid and alkali to obtain pure cubic boron nitride crystals, and sieved with a sieve to obtain cubi...

Embodiment 3

[0024] A kind of synthetic method of cubic boron nitride, concrete process is as follows:

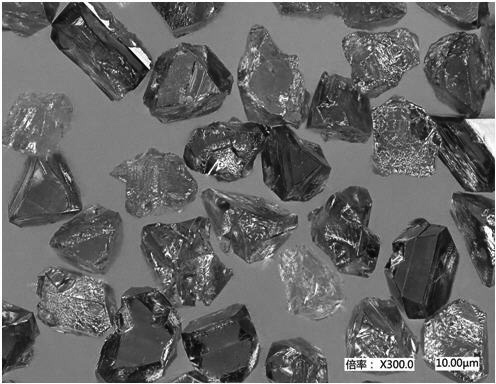

[0025] LiAlH 4 Powder, Li 3 N powder and Li 3 BN 2 Powder is catalyst, and commercially available hBN is raw material (BN content 98.5wt%, B 2 o 3 0.4%), by mass ratio NaAlH 4 : Li 3 N: Li 3 BN 2: hBN=2︰5︰8︰100 The ratio is to take the materials separately, mix them uniformly and press them into a cylinder, put them into a graphite heating tube to make a composite rod, assemble with pyrophyllite and other components to form an assembly block, and put the assembly block into six In the synthesis cavity of the surface-top press, pressurize to 4.9GPa, keep it for 7 minutes after the temperature reaches 1500°C, stop heating after the synthesis, wait for 3 minutes and then release the pressure. The composition was taken out, crushed, soaked in water, and treated with conventional acid and alkali to obtain pure cubic boron nitride, and sieved with a sieve to obtain cubic boron nitrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com