Method for manufacturing raw material balls and cement raw materials by reusing industrial waste mud titanium gypsum

An industrial technology of titanium gypsum, which is applied in the field of industrial waste mud titanium gypsum to make raw material balls and cement raw materials, to achieve the effects of convenient transportation, increased strength and density, and convenient measurement and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Titanium gypsum wet material and titanium gypsum dry material are used to make raw material balls. The titanium gypsum wet material is the filter mud titanium gypsum discharged from the current production, with a water content greater than 40%. The dry titanium gypsum material contains less than 15%. Blocky titanium gypsum.

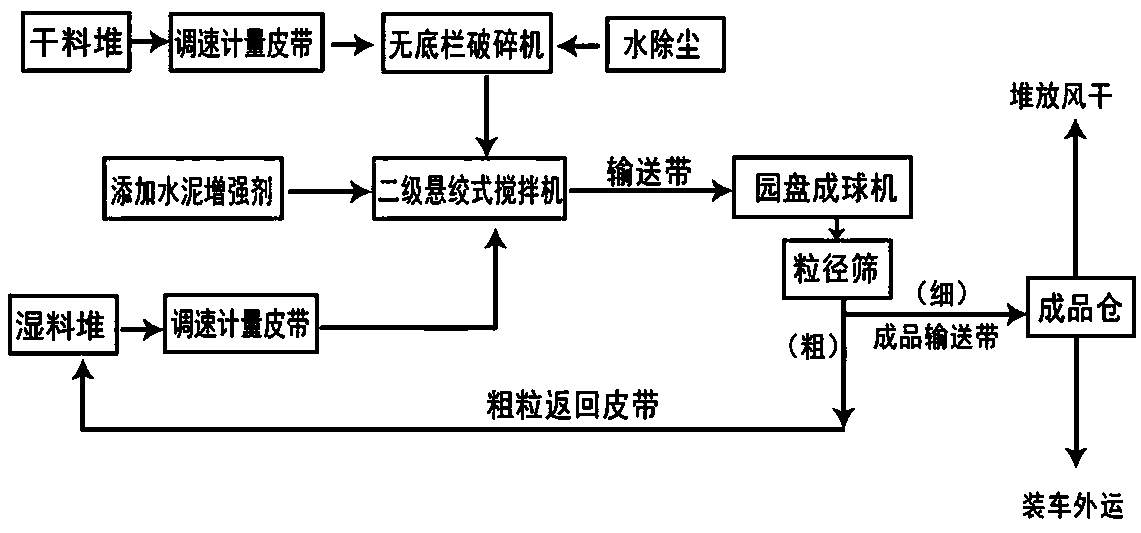

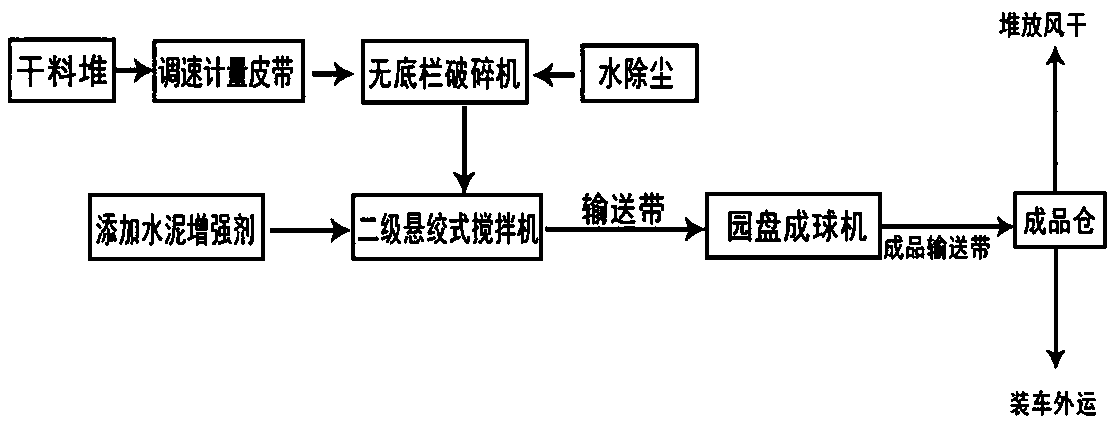

[0027] Production steps such as figure 1 Shown:

[0028] Step 1); The titanium gypsum wet material and the titanium gypsum dry material are conveyed and measured by speed-regulating metering belts respectively. After the titanium gypsum dry material is measured, it is crushed into fine powder with a bottomless crusher. When the titanium gypsum dry material is crushed, it can pass Water dedusting collects and treats the dust in the crusher to avoid dust pollution. The fine powder granular titanium gypsum dry material and the measured titanium gypsum wet material are put into the secondary suspension mixer, and the secondary suspension mixer mixes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com