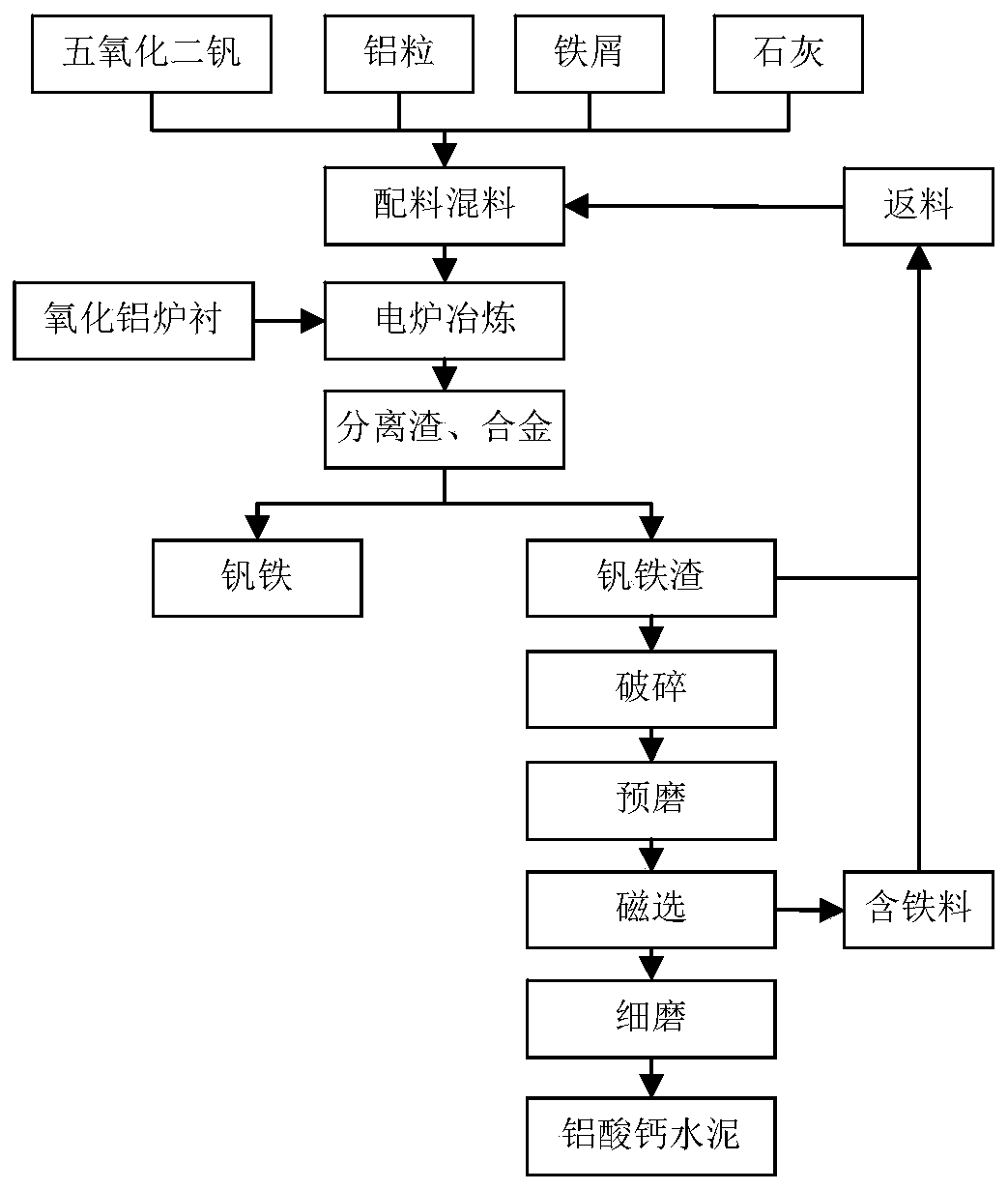

Method for co-producing ferrovanadium and calcium aluminate cement

A technology of calcium aluminate cement and ferrovanadium, which is applied in the direction of cement production, etc., can solve the problems of restricting the application of high added value and the fluctuation of magnesium oxide content, so as to improve the added value of utilization, reduce the melting point, and reduce the loss of vanadium Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

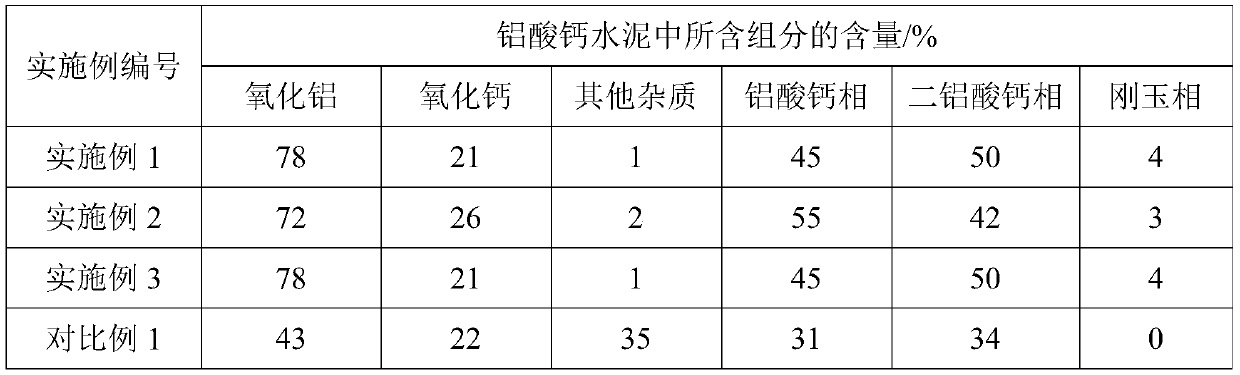

Embodiment 1

[0050] (1) After mixing the fused corundum aggregate of 65 parts by weight, the corundum fine powder of 20 parts by weight, the CA-70 calcium aluminate cement of 12 parts by weight and the aluminum dihydrogen phosphate of 3 parts by weight, the furnace lining is knotted, Then the knotted furnace lining is maintained for 3 days, and it is used after drying, wherein the particle size of the fused corundum aggregate is 0.5mm, and the particle size of the corundum fine powder is less than 0.1mm;

[0051] (2) Vanadium pentoxide, aluminum particles, lime and iron filings are made into a mixture, wherein, the total amount of the mixture is 100 parts by weight, and the content of the lime is 20 parts by weight, and the composition The aluminum coefficient is 100%, and the iron distribution coefficient is 105%;

[0052] (3) The mixture in step (2) is added in the electric furnace, and the electric furnace is turned on to smelt at 1850°C. During the smelting process, detect the content ...

Embodiment 2

[0055] (1) After mixing the fused corundum aggregate of 65 parts by weight, the corundum fine powder of 20 parts by weight, the CA-70 calcium aluminate cement of 10 parts by weight and the aluminum dihydrogen phosphate of 5 parts by weight, the furnace lining is knotted, Then the knotted furnace lining is maintained for 4 days, and it is used after drying, wherein the particle size of the fused corundum aggregate is 5mm, and the particle size of the corundum fine powder is less than 0.08mm;

[0056] (2) Vanadium pentoxide, aluminum particles, lime and iron filings are made into a mixture, wherein, based on 100 parts by weight of the total amount of the mixture, the content of the lime is 25 parts by weight, and the mixture The aluminum coefficient is 106%, and the iron distribution coefficient is 22%;

[0057] (3) The mixture in step (2) is added in the electric furnace, and the electric furnace is turned on to smelt at 1900°C. During the smelting process, detect the content o...

Embodiment 3

[0060] Co-production of ferrovanadium and calcium aluminate cement according to the method described in Example 1, the difference is that in step (3), the smelting temperature is 1800°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com