Method for preparing two alkalis and co-producing high-purity gypsum from mirabilite and limestone through PCET reaction

A technology of limestone and reaction, applied in the direction of electrodes, calcium/strontium/barium sulfate, electrolysis process, etc., can solve the problems of high environmental pressure, high energy consumption, high energy consumption of electrolysis, etc., and achieve the goal of reducing manufacturing energy consumption and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

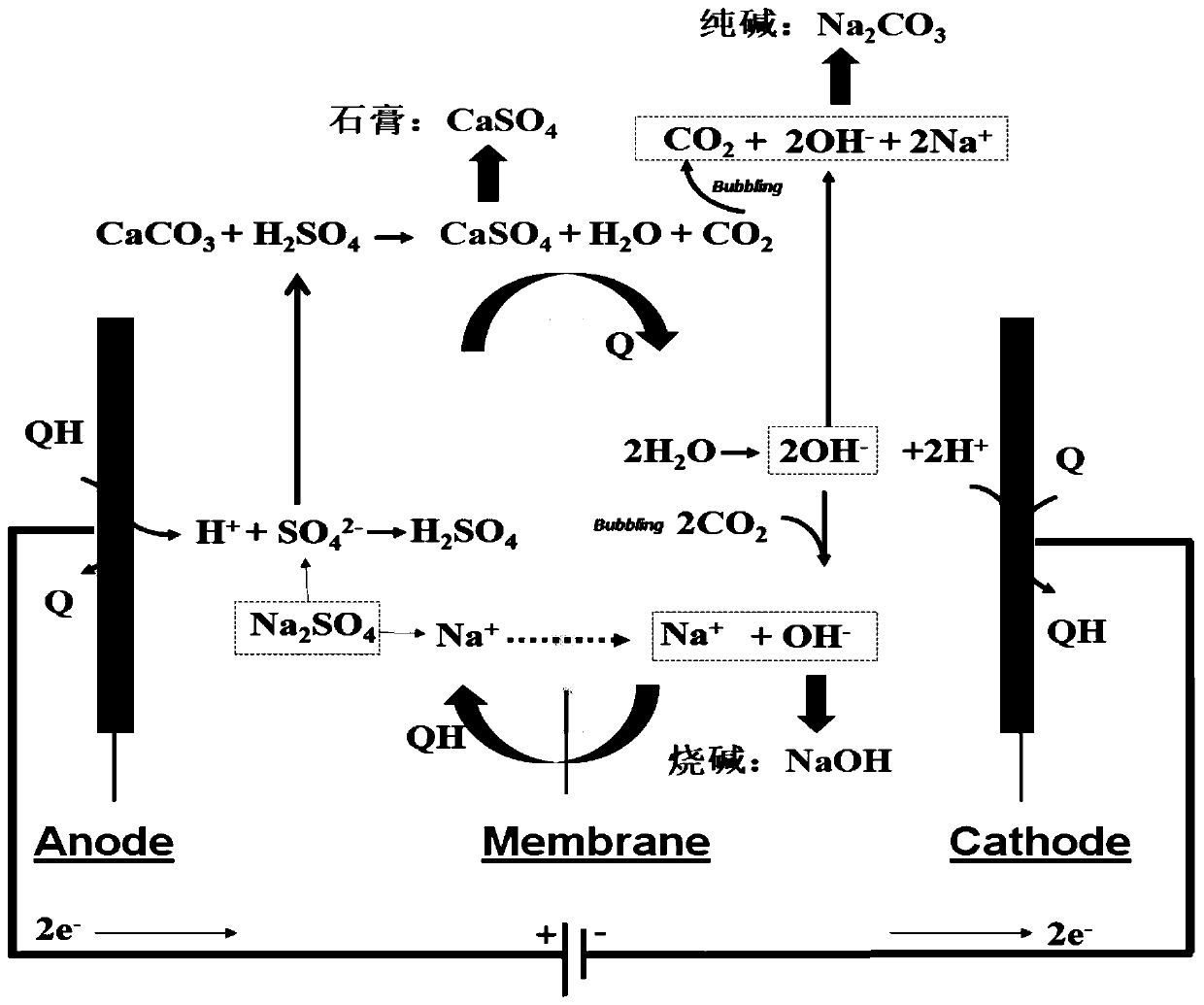

[0089] In this embodiment, the process of producing soda ash and co-producing high-purity gypsum with Glauber's salt and limestone by PCET reaction is as follows:

[0090] The cation exchange membrane is placed in the electrolytic cell and the electrolytic cell is divided into an anode area and a cathode area. The anode area adds 50ml sodium acetate solution (concentration is 2M) as the anolyte, and the cathode area adds 50ml sodium carbonate (concentration is 3M). Bubble CO into the cathode area at a rate of 10ml / min 2 Gas for 5 minutes, the electrolyte is continuously circulated into the electrode chamber of the electrolytic cell by a peristaltic pump at a flow rate of 20mL / min, and 0.3mol / L riboflavin-5-phosphate (FMN, ) as the cathode electrocatalyst, adding 0.3mol / L reduced riboflavin (FMNH 2 , ) as the anode electrocatalyst, and a DC power supply (IT6932A, Itech) was applied between the anode electrode and the cathode electrode to provide the current.

[0091] Among...

Embodiment 2

[0100] In this embodiment, the process of producing soda ash and co-producing high-purity gypsum with Glauber's salt and limestone by PCET reaction is as follows:

[0101] The cation exchange membrane is placed in the electrolytic cell and the electrolytic cell is divided into an anode area and a cathode area. The anode area adds 50ml sodium formate solution (concentration is 3M) as the anolyte, and the cathode area adds 50ml sodium carbonate (concentration is 2M). The cathode area was bubbled into CO at a rate of 20ml / min 2 gas, the electrolyte is continuously circulated into the electrode chamber of the electrolytic cell through a peristaltic pump at a flow rate of 20mL / min, and 0.1mol / L of As the cathode electrocatalyst Q, add 0.1mol / L of As the anode electrocatalyst QH, a DC power supply (IT6932A, Itech) was applied between the anode and cathode electrodes to provide current.

[0102] Among them, the anode electrode is carbon felt, the cathode electrode is carbon felt,...

Embodiment 3

[0111] The present embodiment utilizes PCET reaction to produce caustic soda co-production process of high-purity gypsum with Glauber's salt and limestone as follows:

[0112] The cation exchange membrane is placed in the electrolytic cell and the electrolytic cell is divided into an anode area and a cathode area. The anode area adds 50ml sodium formate solution (concentration is 3M) as the anolyte, and the cathode area adds 50ml sodium hydroxide (concentration is 1M). The peristaltic pump continuously circulates the electrolyte into the electrode chamber of the electrolytic cell at a flow rate of 20mL / min, and at the same time adds 2mol / L of As the cathode electrocatalyst Q, add 2mol / L of As the anode electrocatalyst QH, a DC power supply (IT6932A, Itech) was applied between the anode and cathode electrodes to provide current.

[0113] Among them, the anode electrode is carbon cloth, the cathode electrode is carbon cloth, and the current density is 55.6mA / cm 2 When the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com