Metal surface with efficient dropwise condensation function and preparation method thereof

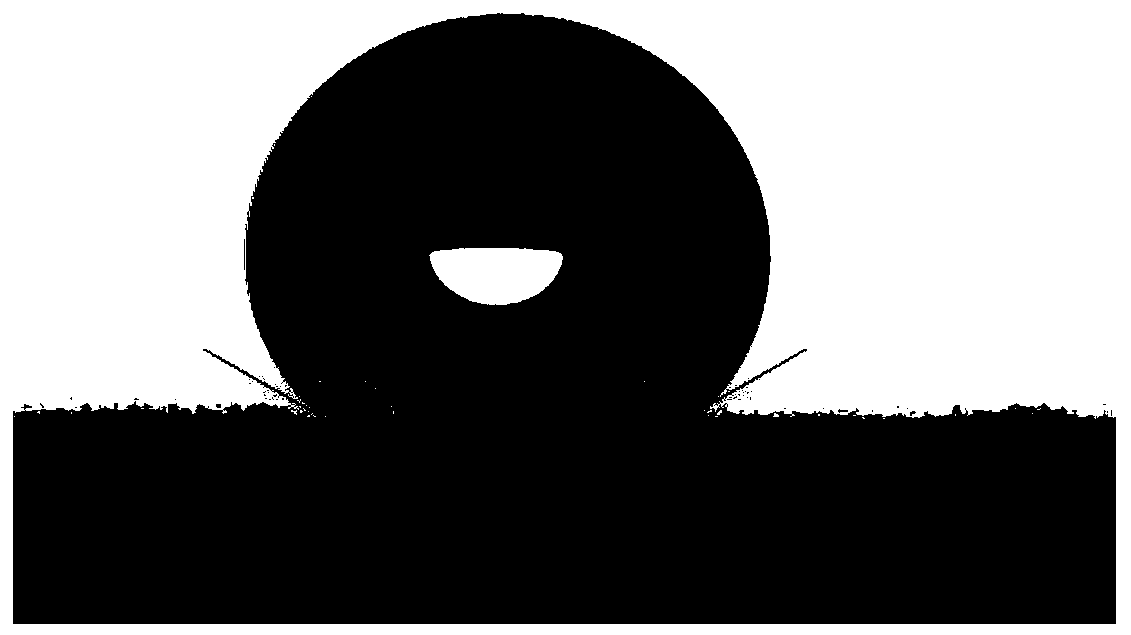

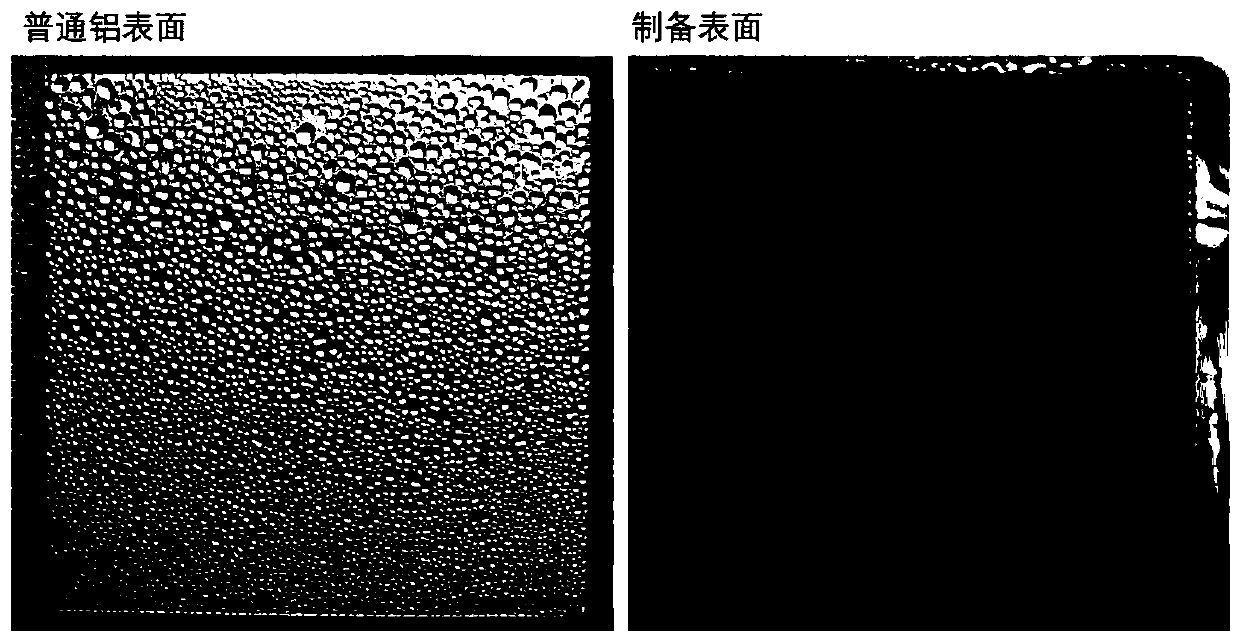

A metal surface, droplet condensation technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of complex technical methods and high application costs, to promote the condensation process, avoid the formation of condensation droplets, and be flexible. The effect of flexibility and designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of the metal substrate: use mechanical processing to smooth the surface of the aluminum sheet, clean and dry it for use;

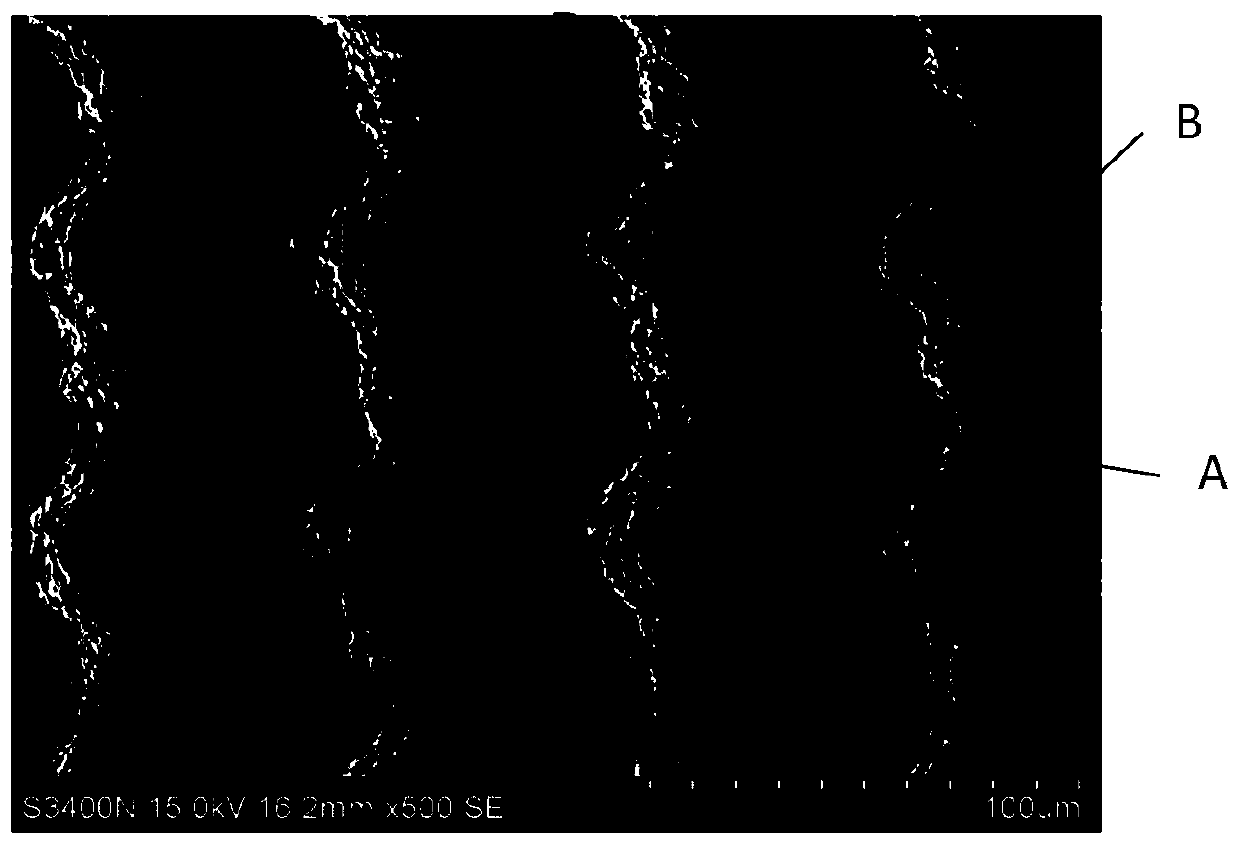

[0032] 2. Laser processing: using a femtosecond laser with a pulse width of 800 femtoseconds (repetition frequency 40kHz, average power 10W), combined with an X-Y scanning galvanometer and a flat field mirror, the laser is focused into a spot with a diameter of 40 μm, so that the laser beam The aluminum surface was ablated row by column at a speed of 100 mm / s, and the scanning pitch of each row and column was 40 μm. After laser treatment, the aluminum surface forms a periodic micro-nano structure with a papillary microstructure, that is, periodically distributed cone-shaped micron protrusions and nanoparticles on the protruding surface (the product of laser ablation), and the period of the micron-scale protrusions is about 40 μm , with a depth of about 30 μm.

[0033] 3. Surface modification: Rinse and dry the aluminum sheet treated ...

Embodiment 2

[0037] 1. Preparation of the metal substrate: firstly, the surface of the aluminum sheet is smoothed by mechanical processing, and then cleaned and dried for use;

[0038]2. Laser processing: Femtosecond pulsed laser (wavelength 532nm, pulse width 300 femtoseconds, repetition frequency 40kHz, average power 10W) is used, combined with X-Y scanning galvanometer and flat field mirror, the focusing spot is 30μm. The copper surface is ablated row by row and column by row, and the spacing between each row and each column is 30 μm. The scanning speed of the laser beam is 60mm / s. After laser treatment, the copper surface forms a periodic micro-nanostructure with a papillary microstructure, that is, periodically distributed micron-scale protrusions and nanoparticles (products of laser ablation) that protrude from the surface. The periods of micron-scale protrusions are all about 30 μm, and the depth of the microstructure is about 25 μm;

[0039] 3. Surface modification: Clean and d...

Embodiment 3

[0042] 1. Preparation of the metal base material: Firstly, the surface of the titanium alloy sheet is ground flat by mechanical processing, cleaned and dried for later use;

[0043] 2. Laser processing: Femtosecond pulsed laser (wavelength 532nm, pulse width 300 femtoseconds, repetition frequency 40kHz, average power 10W) is used, combined with X-Y scanning galvanometer and flat field mirror, the focusing spot is 30μm. The copper surface is ablated row by row and column by row, and the spacing between each row and each column is 30 μm. The scanning speed of the laser beam is 60mm / s. After laser treatment, a periodic micro-nano structure with a papillary microstructure is formed on the surface of the titanium alloy, that is, periodically distributed micron-scale protrusions and nanoparticles (products of laser ablation) that protrude from the surface. The periods of micron-scale protrusions are all about 100 μm, and the depth of the microstructure is about 50 μm;

[0044] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse repetition frequency | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com