Method for manufacturing multifunctional nano bed sheet

A production method and multi-functional technology, which is applied in the field of fabric processing, can solve the problems of bed sheet performance degradation, etc., and achieve the effects of keeping clean and tidy, inhibiting microbial reproduction, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

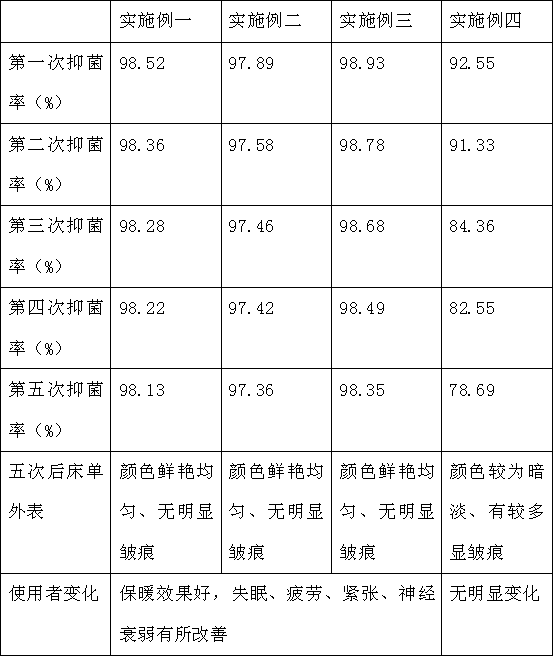

Examples

Embodiment 1

[0021] A method for making a multifunctional nano sheet, comprising a multifunctional nano sheet, the multifunctional nano sheet includes main materials and auxiliary materials, the main material includes warp yarns and weft yarns, and the warp yarns and weft yarns are made of synthetic fibers, cotton linen, cotton fibers, wool One or more of fiber, flax fiber, silk and bamboo fiber are mixed, and the auxiliary materials include nano inorganic antibacterial agent and far-infrared ceramic powder;

[0022] The preparation method of described multifunctional nano sheet, comprises the following steps:

[0023] Step 1: Prepare the warp yarn and weft yarn required for the bed sheet through the loom. During the preparation process, add an appropriate amount of far-infrared ceramic powder to the limit spinning solution of the surface raw materials of the warp yarn and weft yarn. The weight of the far-infrared ceramic powder and the main material is according to 1:80 specific gravity a...

Embodiment 2

[0028] A method for making a multifunctional nano sheet, comprising a multifunctional nano sheet, the multifunctional nano sheet includes main materials and auxiliary materials, the main material includes warp yarns and weft yarns, and the warp yarns and weft yarns are made of synthetic fibers, cotton linen, cotton fibers, wool One or more of fiber, flax fiber, silk and bamboo fiber are mixed, and the auxiliary materials include nano inorganic antibacterial agent and far-infrared ceramic powder;

[0029] The preparation method of described multifunctional nano sheet, comprises the following steps:

[0030] Step 1: Prepare the warp yarn and weft yarn required for the bed sheet through the loom. During the preparation process, add an appropriate amount of far-infrared ceramic powder to the limit spinning solution of the surface raw materials of the warp yarn and weft yarn. The weight of the far-infrared ceramic powder and the main material is according to 1:100 specific gravity ...

Embodiment 3

[0035] A method for making a multifunctional nano sheet, comprising a multifunctional nano sheet, the multifunctional nano sheet includes main materials and auxiliary materials, the main material includes warp yarns and weft yarns, and the warp yarns and weft yarns are made of synthetic fibers, cotton linen, cotton fibers, wool One or more of fiber, flax fiber, silk and bamboo fiber are mixed, and the auxiliary materials include nano inorganic antibacterial agent and far-infrared ceramic powder;

[0036] The preparation method of described multifunctional nano sheet, comprises the following steps:

[0037] Step 1: Prepare the warp yarn and weft yarn required for the bed sheet through the loom. During the preparation process, add an appropriate amount of far-infrared ceramic powder to the limit spinning solution of the surface raw materials of the warp yarn and weft yarn. The weight of the far-infrared ceramic powder and the main material is according to Addition of 1:90 specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com