A kind of preparation method of environment-friendly rubber and plastic foam product not containing formamide

A rubber-plastic foaming, environmentally friendly technology, applied in the field of foaming materials, can solve the problems of unfavorable foaming process of foaming materials, affecting the absorption effect of formamide, increasing the amount of foaming agent used, etc., to achieve excellent fire resistance, improve The effect of hardness and porosity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

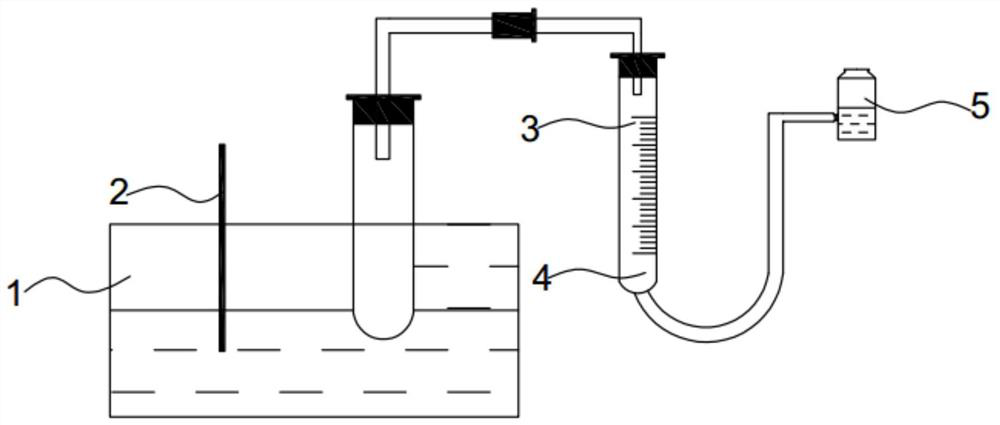

Image

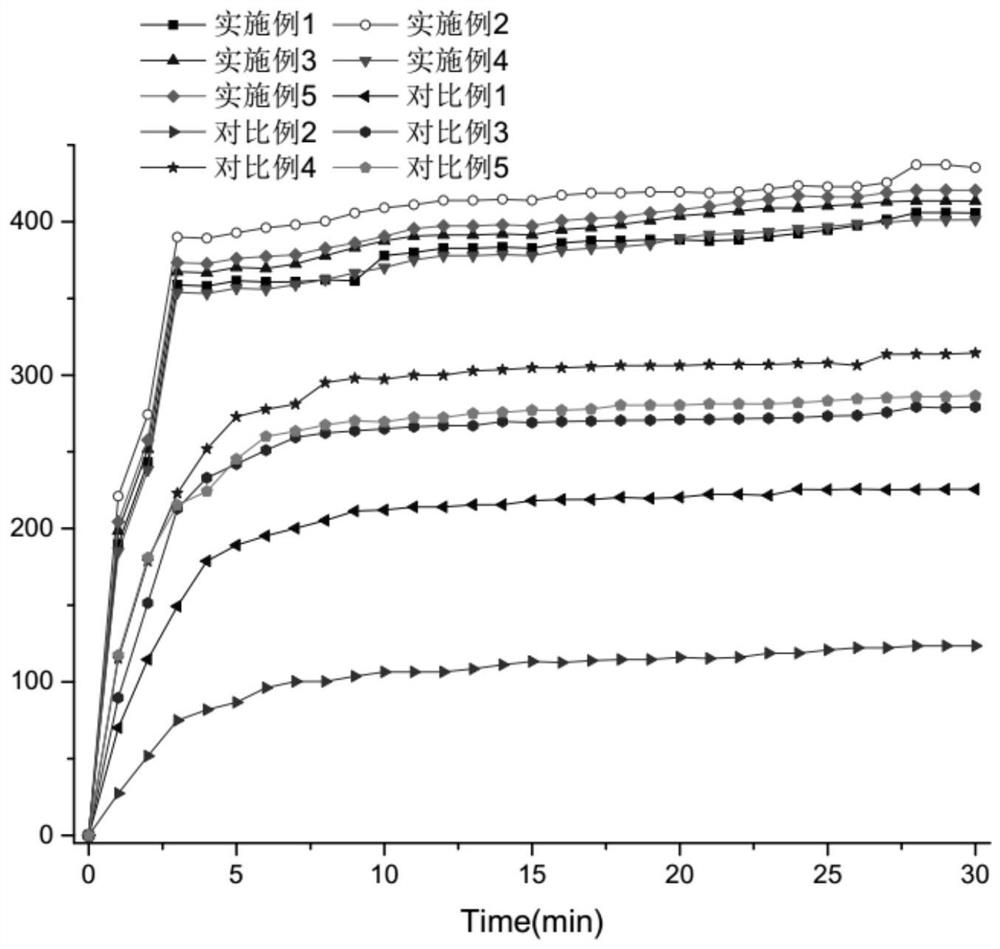

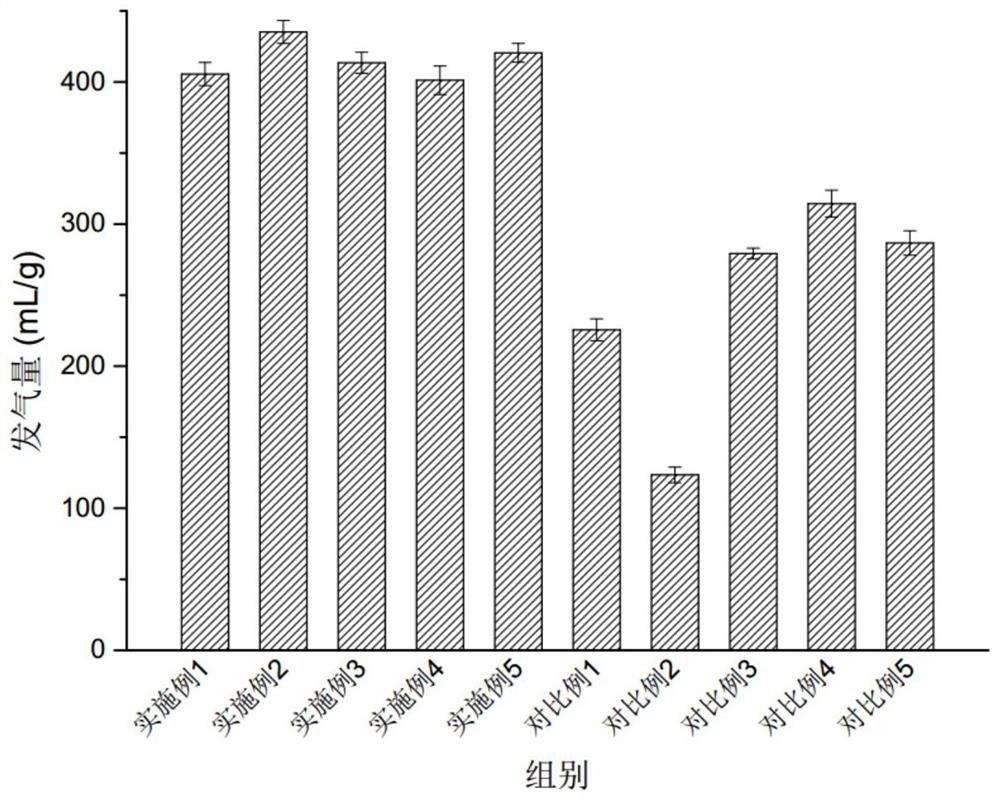

Examples

preparation example Construction

[0048] In one embodiment of the present invention, the preparation method of the foaming agent composition comprises the following steps: in the aqueous dispersion medium containing the dispersion stabilizer, the mixture of the shell material, the polymerizable monomer for the shell material and the crosslinking agent is suspended and polymerized , thereby manufacturing the above-mentioned blowing agent composition.

[0049] In one embodiment of the present invention, the core also contains caffeic acid amide derivatives shown in formula (I) and cinnamic acid derivatives shown in formula (II),

[0050]

[0051] In the formula, -R is selected from one of the following: -CH 3 , -CH-(CH 3 ) 2 、-CH 2 -CH(CH 3 ) 2 、-CH(CH 3 )-CH 2 -CH 3 、-CH 2 -C 6 h 5 .

[0052] The addition of caffeic acid amide derivatives shown in formula (I) and cinnamic acid derivatives shown in formula (II) can adjust the decomposition temperature and rate of the foam shell material, release g...

Embodiment 1

[0077] A foaming agent composition, comprising a core-shell structure, which has: 100 parts by weight of the core and 3 parts by weight of the shell surrounding the core; wherein,

[0078] The core contains the blowing agent of potassium bicarbonate and 1,2-dinitroguanidine with a weight ratio of 1:1.2, and caffeic acid amide derivatives shown in (I) and cinnamic acid derivatives shown in formula (II),

[0079]

[0080] In formula (I), -R is -CH 3 ; The amount of caffeic acid amide derivatives is 4.2wt% of the amount of whipping agent, the amount of cinnamic acid derivatives is 15.5wt% of the amount of foaming agent; the particle size of potassium bicarbonate is 200-300 mesh;

[0081] The shell was a polymer comprising 63 wt% acrylonitrile and 27 wt% vinylidene chloride monomer.

[0082] The preparation method of above-mentioned whipping agent composition is:

[0083] 1) Mix 210g of 20wt% colloidal silicon dioxide, 9.8g of 50wt% diethanolamine-adipic acid condensation pro...

Embodiment 2

[0087] A foaming agent composition, comprising a core-shell structure, which has: 100 parts by weight of the core and 3 parts by weight of the shell surrounding the core; wherein,

[0088] The core contains the blowing agent of potassium bicarbonate and 1,2-dinitroguanidine with a weight ratio of 1:1.2, and caffeic acid amide derivatives shown in (I) and cinnamic acid derivatives shown in formula (II),

[0089]

[0090] In formula (I), -R is -CH-(CH 3 ) 2 ; The amount of caffeic acid amide derivatives is 4.2wt% of the amount of whipping agent, the amount of cinnamic acid derivatives is 15.5wt% of the amount of foaming agent; the particle size of potassium bicarbonate is 200-300 mesh;

[0091] The shell was a polymer comprising 63 wt% acrylonitrile and 27 wt% vinylidene chloride monomer.

[0092] The preparation method of above-mentioned blowing agent composition is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com