Carbon-supported ruthenium phosphide nanocluster dual-functional catalyst, and preparation method and application thereof

A bifunctional catalyst and nanocluster technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of expensive carrier, cost limitation, complicated preparation process of Co catalyst, etc., and achieve excellent activity and high performance. Stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

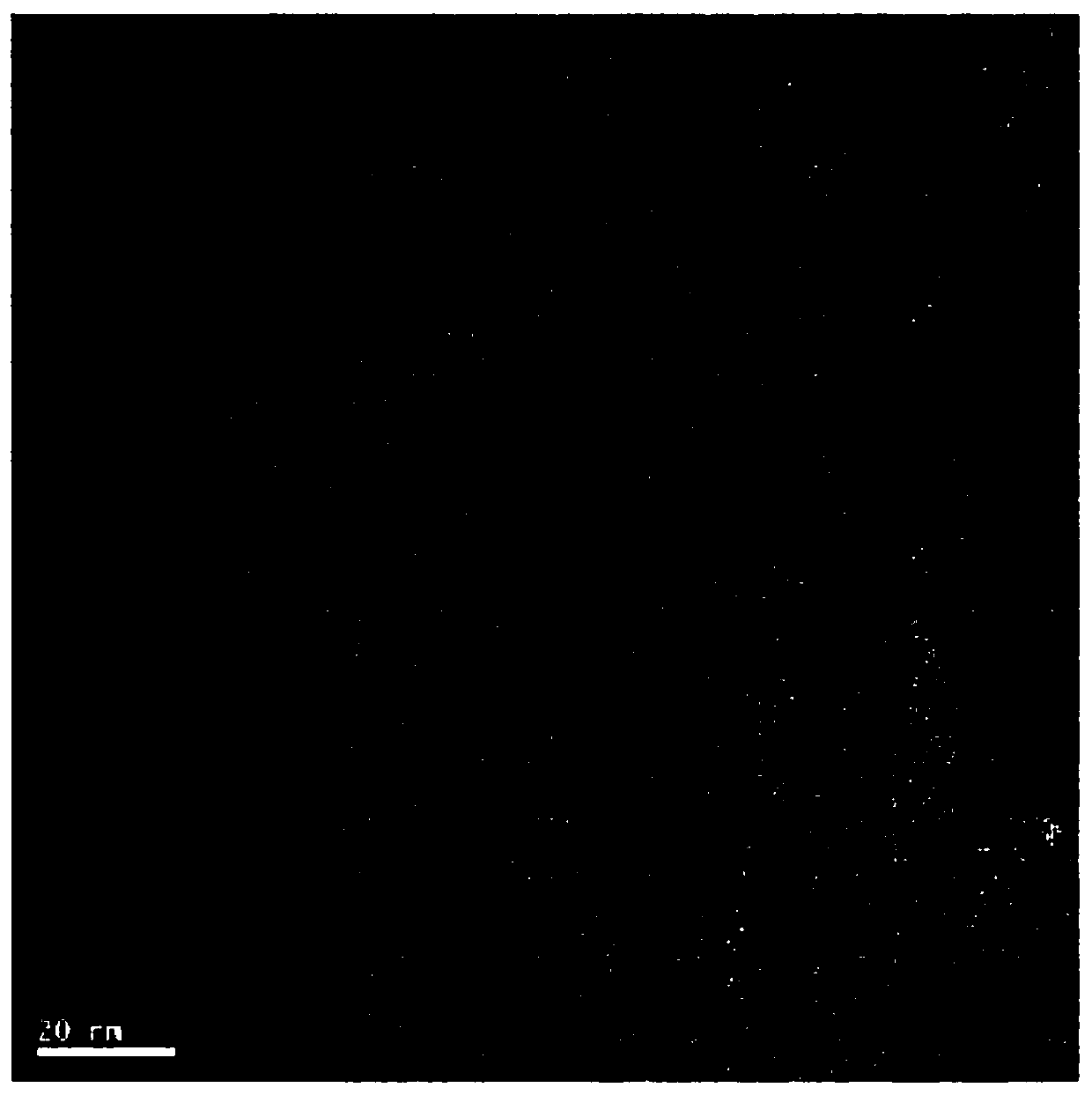

[0030] Add 0.5 g of activated carbon powder (170-220 mesh in particle size) into 50 mL of water at room temperature, and ultrasonically disperse the activated carbon to obtain the first suspension; add 1 mL of 10 mg / mL RuCl 3 The aqueous solution was added dropwise to the first suspension, and stirred at room temperature for 3 h, so that the RuCl 3 Fully adsorbed on the surface of activated carbon to obtain the second suspension.

[0031] At a temperature of 80° C., the second suspension was continuously stirred until all the water was evaporated to obtain the first solid powder. The first solid powder and 100 mg of sodium hypophosphite are fully ground in a mortar, and the ground mixed powder is transferred to a porcelain boat, and the porcelain boat is placed in a tube furnace for calcination under a nitrogen atmosphere. The calcination process is as follows: It was heated from room temperature to 600 °C at a rate of 5 °C / min, and maintained at 600 °C for 5 h, and then natu...

Embodiment 2

[0035] Add 1 g of activated carbon powder (170-220 mesh in particle size) to 120 mL of water at room temperature, and ultrasonically disperse the activated carbon to obtain the first suspension; add 2.2 mL of 10 mg / mL RuCl 3 The aqueous solution was added dropwise to the first suspension, and stirred at room temperature for 4 h, so that the RuCl 3 Fully adsorbed on the surface of activated carbon to obtain the second suspension.

[0036] At a temperature of 78° C., the second suspension was continuously stirred until all the water was evaporated to obtain the first solid powder. The first solid powder and 500 mg sodium hypophosphite are fully ground in a mortar, and the ground mixed powder is transferred to a porcelain boat, and the porcelain boat is placed in a tube furnace for calcination under a nitrogen atmosphere. The calcination process is as follows: It was heated from room temperature to 650 °C at a rate of 7 °C / min, and maintained at 650 °C for 4.5 h, and then natura...

Embodiment 3

[0038] Add 0.3 g of activated carbon powder (170-220 mesh in particle size) to 50 mL of water at room temperature, and ultrasonically disperse the activated carbon to obtain the first suspension; add 0.7 mL of 10 mg / mL tris(acetylacetonate ) ruthenium(III) aqueous solution was added dropwise to the first suspension, and stirred at room temperature for 3 h, so that tris(acetylacetonate)ruthenium(III) was fully adsorbed on the surface of activated carbon to obtain a second suspension.

[0039] At a temperature of 90° C., the second suspension was continuously stirred until all the water was evaporated to obtain the first solid powder. The first solid powder and 60 mg of sodium hypophosphite are fully ground in a mortar, and the ground mixed powder is transferred to a porcelain boat, and the porcelain boat is placed in a tube furnace for calcination under a nitrogen atmosphere. The calcination process is as follows: It was heated from room temperature to 700 °C at a rate of 7 °C / ...

PUM

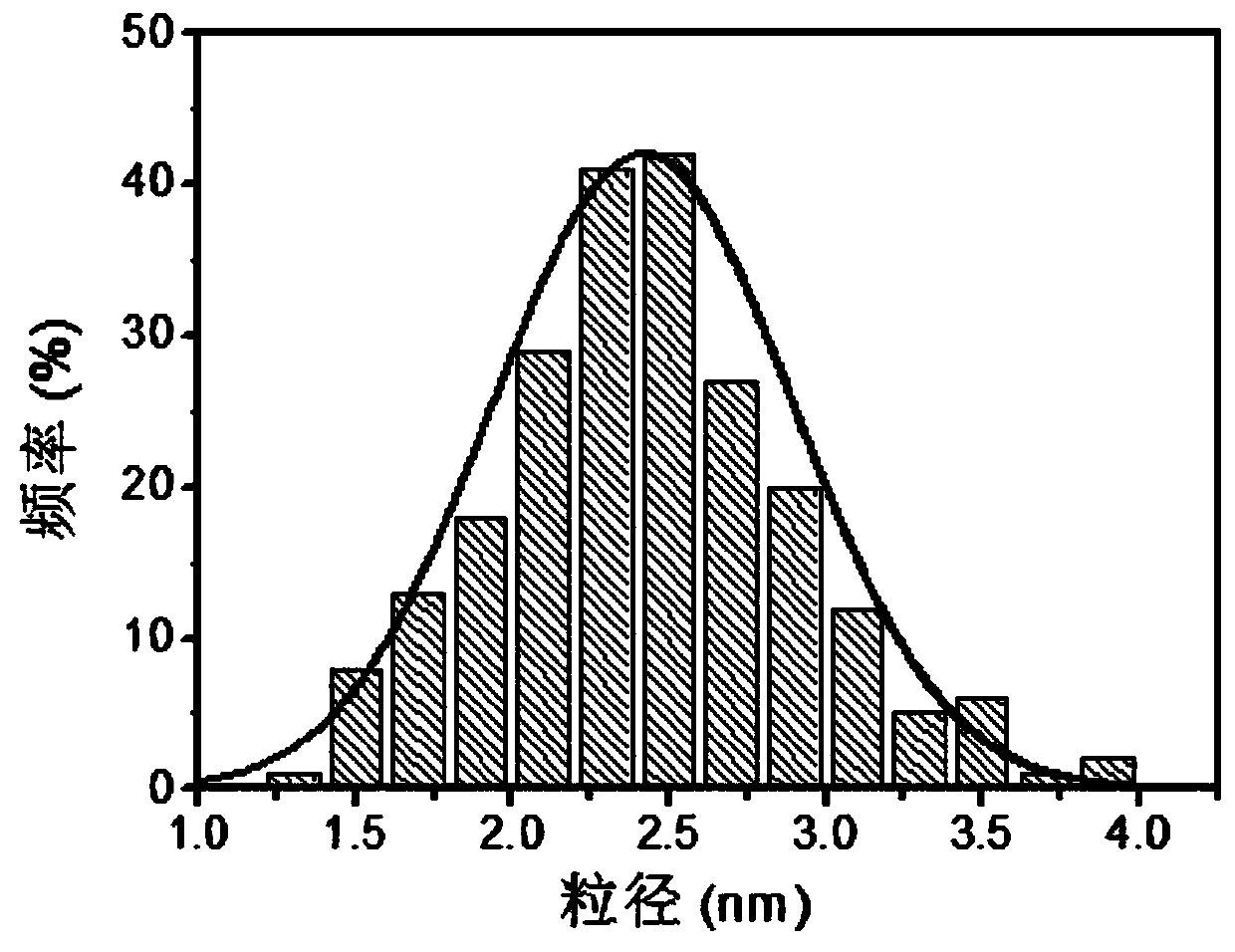

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com