Composite material for processing micro-type bone retention pin and preparation method of composite material

A composite material and a technology of combining materials, which are applied in the field of composite materials for processing miniature bone fixation nails and the field of preparation thereof, can solve the problems of low surface bioactivity, no osteoinductive performance, and increase the pain of patients, and are convenient for popularization and application. The effect of excellent processing performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

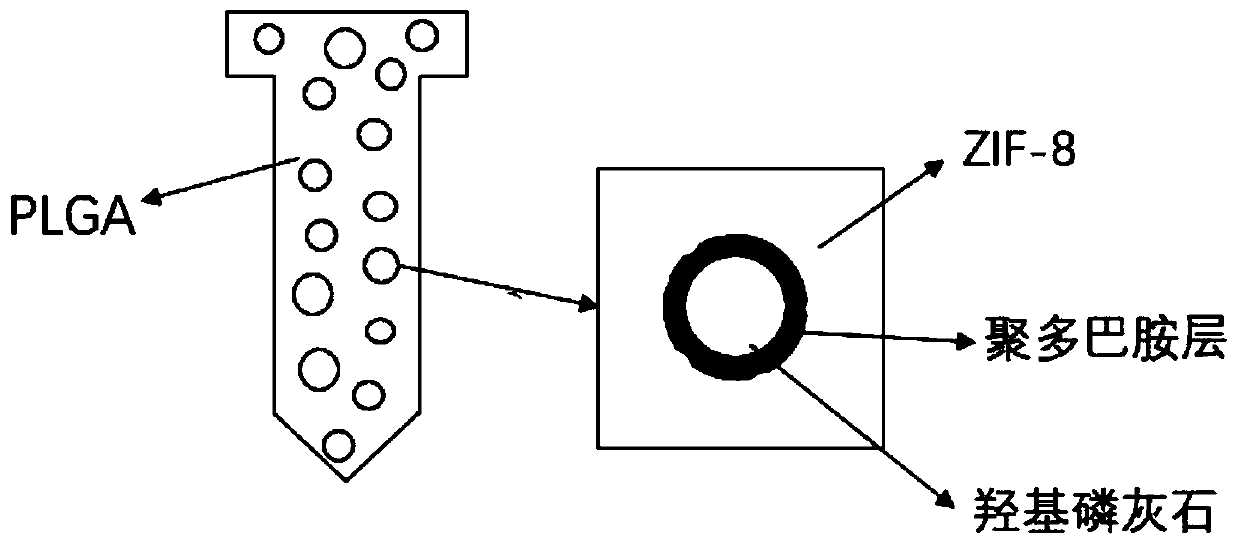

[0040]Add 4.5 parts of hydroxyapatite and 2 parts of zeolite imidazole lipid structure material ZIF-8 to 0.5 part of dopamine hydrochloride solution and stir, and adjust the pH to 8.47, and continue stirring at room temperature for 6 hours, so that dopamine hydrochloride Coat ZIF-8 on hydroxyapatite; first add the material prepared in the above steps into a high-speed blender, then add 93 parts of PLGA to make it uniformly dispersed, and finally carry out the mixture at 180°C The composite material of ZIF-8 / PLGA / β-tricalcium phosphate / polydopamine can be obtained by banburying, blending and granulation; the composite material is processed into miniature bone retention by micro-injection molding machine at 180°C and 300bar pressure nail.

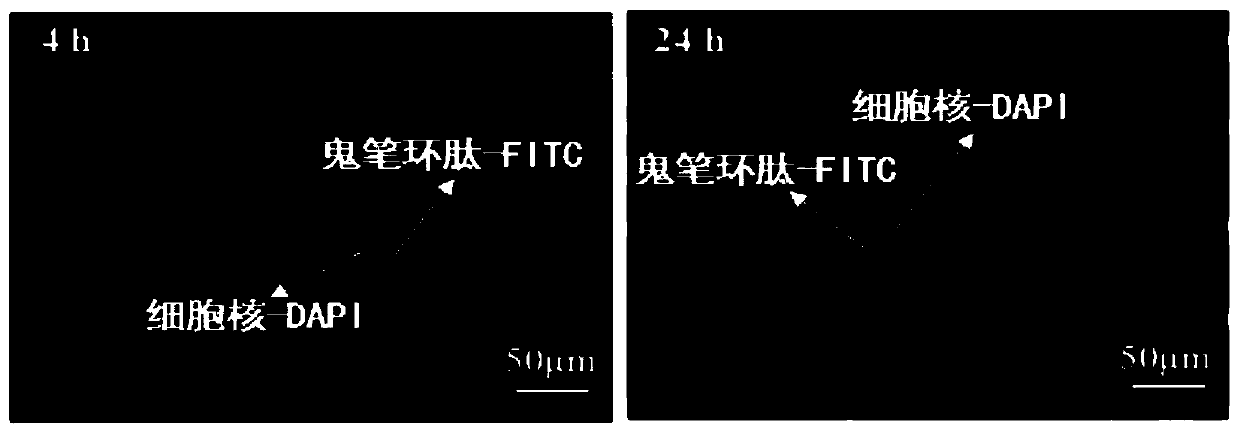

[0041] The tensile strength of the obtained miniature bone fixation nail was 82.71 MPa. Rat mesenchymal stem cells (rBMSCs) were inoculated on the surface of miniature bone fixation nails, and blank control wells containing only medium were ...

Embodiment 2

[0043] Add 4.5 parts of hydroxyapatite and 2 parts of zeolite imidazole lipid structure material ZIF-8 to 0.5 part of dopamine hydrochloride solution and stir, and adjust the pH to 8.47, and continue stirring at room temperature for 6 hours, so that dopamine hydrochloride Coat ZIF-8 on hydroxyapatite; first add the material prepared in the above steps into a high-speed blender, then add 93 parts of PLA to make it uniformly dispersed, and finally carry out the mixture at 180°C The composite material is obtained by banburying, blending and granulating; the composite material is processed into a miniature bone-retaining nail by a micro-injection molding machine at 180° C. and a pressure of 300 bar.

[0044] The tensile strength of the obtained miniature bone fixation nail was 82.56MPa. Rat mesenchymal stem cells (rBMSCs) were inoculated on the surface of miniature bone fixation nails, and blank control wells containing only medium were set up to inoculate the same number of cells...

Embodiment 3

[0046] Add 4.5 parts of hydroxyapatite and 2 parts of zeolite imidazolate structure material ZIF-8 to a solution of 0.5 parts of citric acid and stir, and adjust the pH to 8.47, and continue to stir for 6 hours at room temperature, so that the citric acid Coat ZIF-8 on hydroxyapatite; first add the material prepared in the above steps into a high-speed blender, then add 93 parts of PLGA to make it uniformly dispersed, and finally carry out the mixture at 180°C ZIF-8 / PLGA / hydroxyapatite / polycitric acid composite material is obtained by banburying, blending and granulation; the composite material is processed into a miniature bone retention nail by a micro-injection molding machine at 180°C and a pressure of 300bar .

[0047] The tensile strength of the obtained miniature bone fixation nail was 82.47MPa. Rat mesenchymal stem cells (rBMSCs) were inoculated on the surface of miniature bone fixation nails, and blank control wells containing only medium were set up to inoculate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com