Coin-making copper alloy blank cake electrolyte plasma polishing solution and polishing process

A copper alloy and electrolyte technology, which is applied in the field of ion polishing liquid and polishing technology, can solve the problems of low brightness, unsuitable copper alloy for coinage, roughness of copper alloy blank cake that cannot meet the requirements for coinage, etc., and achieve short polishing time , The surface of the flat cake is bright, and the effect of meeting the surface quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The material of the flat cake polished in the present embodiment is that the grade is CuAl 6 Ni 2 Mint Aluminum Bronze.

[0034] The electrolyte plasma polishing solution prepared in this embodiment has the following components and concentrations: 1% ammonium phosphate, 1% potassium aluminum sulfate, 0.2% citric acid, 0.4% sodium citrate, 0.1% brightener, and the rest is water, polishing The pH range of the liquid is 6~7.

[0035] Concrete polishing process is as follows in the present embodiment:

[0036] 1) Add the polishing solution into the polishing tank in the electrolyte plasma polishing machine and heat it to 65°C.

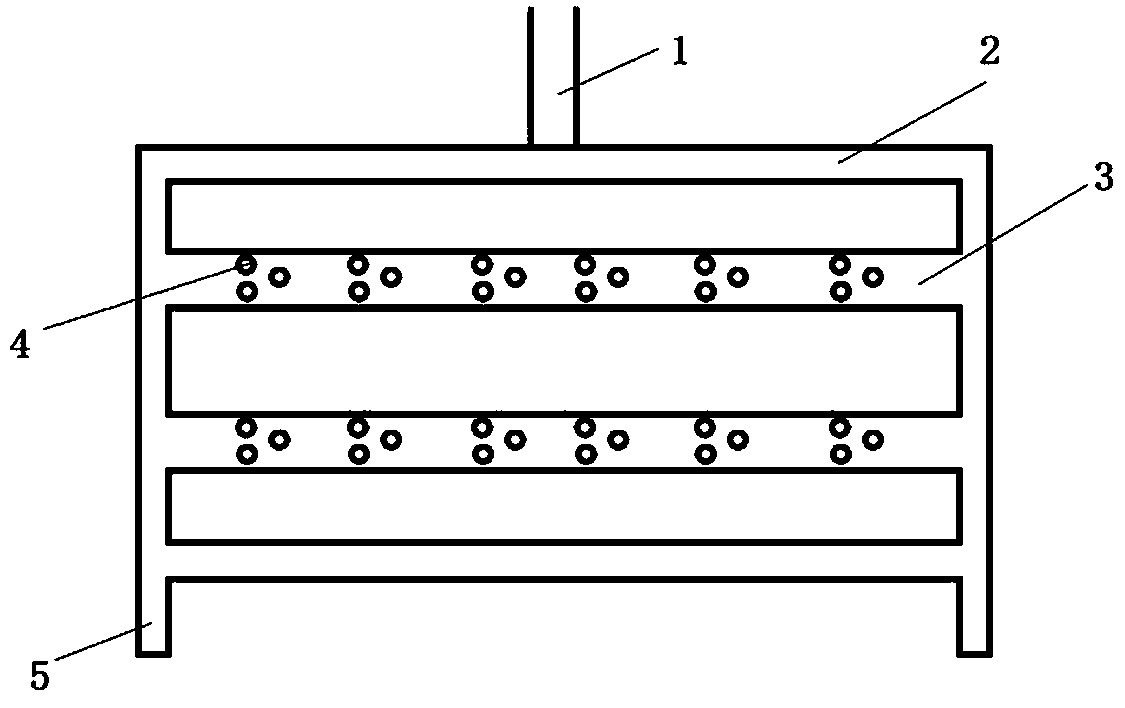

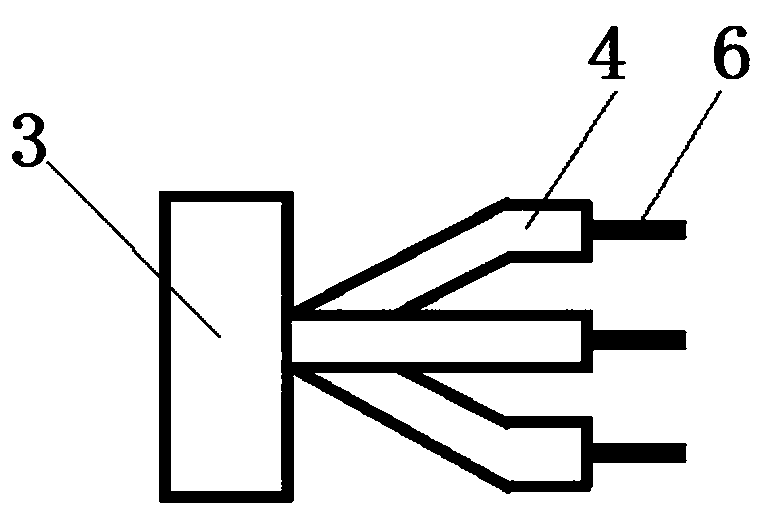

[0037] 2) Clamp the copper alloy blank cake to be polished on the special polishing hanger.

[0038] 3) Hang the hanger full of copper alloy blank cakes on the bracket in the electrolyte plasma polishing machine, lower the bracket so that the blank cake on the hanger is immersed in the polishing liquid, and keep it at a position 40mm below the l...

Embodiment 2

[0043] The material of the polished flat cake in this embodiment is coinage tin brass with the grade of HSn72-1-1.

[0044] The electrolyte plasma polishing solution prepared in this embodiment has the following components and concentrations: 2% ammonium phosphate, 3.5% potassium aluminum sulfate, 0.8% citric acid, 0.7% sodium citrate, 0.8% brightener, and the rest is water, polishing The pH range of the solution is 7.

[0045] Concrete polishing process is as follows in the present embodiment:

[0046] 1) Add the polishing solution into the polishing tank in the electrolyte plasma polishing machine and heat it to 85°C.

[0047] 2) Clamp the copper alloy blank cake to be polished on the special polishing hanger.

[0048] 3) Hang the hanger full of copper alloy blank cakes on the bracket in the electrolyte plasma polishing machine, lower the bracket so that the blank cake on the hanger is immersed in the polishing liquid, and keep it at a position 50mm below the liquid surfac...

Embodiment 3

[0053] The material of the polished cake in this embodiment is coinage zinc-nickel-nickel copper with a brand name of BZn15-17.

[0054] The electrolyte plasma polishing solution prepared in the present embodiment has the following components and concentrations: 3% ammonium phosphate, 5% aluminum potassium sulfate, 1.5% citric acid, 1% sodium citrate, 1.5% brightener, and the rest are water. The pH range of the liquid is 7~8.

[0055] Concrete polishing process is as follows in the present embodiment:

[0056] 1) Add the polishing solution into the polishing tank in the electrolyte plasma polishing machine and heat it to 105°C.

[0057] 2) Clamp the copper alloy blank cake to be polished on the special polishing hanger.

[0058] 3) Hang the hanger full of copper alloy blank cakes on the bracket in the electrolyte plasma polishing machine, lower the bracket so that the blank cake on the hanger is immersed in the polishing liquid, and keep it at a position 50mm below the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com